Air-breathing engines, such as jet and ramjet engines, rely on atmospheric oxygen to combust fuel, making them more efficient for sustained flight within Earth's atmosphere. Rocket engines carry both fuel and oxidizer onboard, enabling operation in space where there is no ambient oxygen, but this results in higher fuel consumption and weight. Air-breathing engines offer advantages in specific impulse and fuel economy during atmospheric travel, while rocket engines provide the thrust necessary for orbital insertion and interplanetary missions.

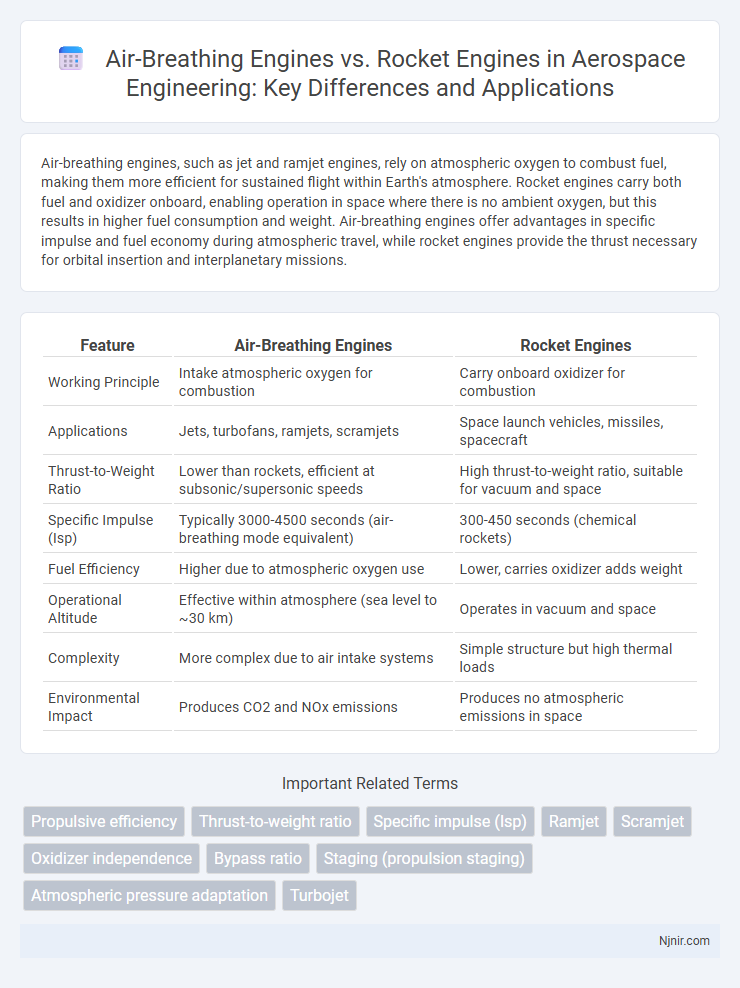

Table of Comparison

| Feature | Air-Breathing Engines | Rocket Engines |

|---|---|---|

| Working Principle | Intake atmospheric oxygen for combustion | Carry onboard oxidizer for combustion |

| Applications | Jets, turbofans, ramjets, scramjets | Space launch vehicles, missiles, spacecraft |

| Thrust-to-Weight Ratio | Lower than rockets, efficient at subsonic/supersonic speeds | High thrust-to-weight ratio, suitable for vacuum and space |

| Specific Impulse (Isp) | Typically 3000-4500 seconds (air-breathing mode equivalent) | 300-450 seconds (chemical rockets) |

| Fuel Efficiency | Higher due to atmospheric oxygen use | Lower, carries oxidizer adds weight |

| Operational Altitude | Effective within atmosphere (sea level to ~30 km) | Operates in vacuum and space |

| Complexity | More complex due to air intake systems | Simple structure but high thermal loads |

| Environmental Impact | Produces CO2 and NOx emissions | Produces no atmospheric emissions in space |

Introduction to Propulsion Systems in Aerospace

Air-breathing engines, such as turbojets and ramjets, utilize atmospheric oxygen to combust fuel, enabling efficient propulsion within Earth's atmosphere and offering lower fuel consumption for subsonic and supersonic flight. Rocket engines carry both fuel and oxidizer onboard, allowing operation in the vacuum of space and providing the high thrust necessary for orbital insertion and deep-space missions. Understanding the distinct performance characteristics and operational environments of air-breathing versus rocket propulsion systems is crucial for designing efficient aerospace vehicles.

Fundamentals of Air-Breathing Engines

Air-breathing engines operate by ingesting atmospheric oxygen to combust fuel, enabling continuous propulsion without carrying oxidizers onboard, which significantly reduces launch mass. These engines rely on high-speed air intake, compression, combustion, and exhaust processes to generate thrust, with turbojets, ramjets, and scramjets as common types. Fundamental challenges include maintaining efficient combustion at varying speeds and altitudes, managing thermal loads, and optimizing the air-fuel mixture for maximum propulsion efficiency.

Rocket Engines: Core Principles

Rocket engines operate on the principle of Newton's third law, expelling high-speed exhaust gases to generate thrust independent of external air. These engines carry both fuel and oxidizer onboard, enabling operation in the vacuum of space where air-breathing engines cannot function. Their ability to produce massive thrust through controlled combustion makes them essential for spacecraft propulsion and launch vehicles.

Propellant Sources: Atmosphere vs. Onboard

Air-breathing engines utilize atmospheric oxygen as the oxidizer, allowing them to carry only fuel onboard, which reduces vehicle weight and increases efficiency during flight within the atmosphere. Rocket engines, in contrast, carry both fuel and oxidizer onboard, enabling operation in the vacuum of space but resulting in higher propellant mass and lower efficiency. The reliance on atmospheric oxygen makes air-breathing engines ideal for sustained flight within Earth's atmosphere, while rocket engines are essential for space travel and maneuvers beyond atmospheric boundaries.

Thrust Generation Mechanisms

Air-breathing engines generate thrust by ingesting atmospheric oxygen to combust fuel, producing high-velocity exhaust gases expelled through a nozzle to propel the aircraft forward. Rocket engines create thrust by combusting onboard propellants, generating high-pressure gases that are expelled at supersonic speeds through a rocket nozzle, independent of atmospheric oxygen. The efficiency of air-breathing engines is limited by atmospheric conditions, whereas rocket engines provide thrust in a vacuum by carrying both fuel and oxidizer.

Efficiency Across Altitude and Velocity

Air-breathing engines, such as jet and ramjet engines, achieve higher efficiency at lower altitudes and subsonic to supersonic speeds by utilizing atmospheric oxygen for combustion, reducing onboard oxidizer weight and increasing specific impulse. Efficiency declines significantly at higher altitudes and hypersonic velocities due to thinner air and decreased oxygen availability, where rocket engines maintain performance by carrying both fuel and oxidizer, enabling operation in a vacuum. Thus, air-breathing engines excel in terrestrial and near-space atmospheric flight regimes, while rocket engines dominate efficiency and thrust in space and extreme velocity conditions.

Applications in Aerospace Missions

Air-breathing engines, such as turbojets and ramjets, excel in atmospheric flight due to their efficient oxygen intake for combustion, making them ideal for commercial airliners and military aircraft operating within Earth's atmosphere. Rocket engines carry both fuel and oxidizer, enabling propulsion in the vacuum of space, which is essential for launching satellites, interplanetary missions, and space exploration vehicles. Hybrid propulsion systems combining air-breathing and rocket engines are increasingly used in aerospace missions to optimize performance across different flight regimes.

Engineering Challenges and Limitations

Air-breathing engines face engineering challenges related to efficient air intake design at varying speeds, thermal management due to oxygen combustion, and limitations in operating altitude and speed because they rely on atmospheric oxygen. Rocket engines overcome atmospheric dependence by carrying both fuel and oxidizer, but they require robust materials to withstand extreme temperatures and pressures, and managing fuel efficiency and thrust-to-weight ratio remains complex. Both engine types exhibit limitations in scalability and durability under prolonged operational stress, influencing their respective applications in aerospace engineering.

Advancements in Hybrid Propulsion

Hybrid propulsion systems combine the efficiency of air-breathing engines with the high thrust of rocket engines, optimizing fuel consumption and extending operational range. Recent advancements in materials science and combustion technology have enabled seamless transitions between atmospheric oxygen intake and onboard oxidizer use, enhancing performance in various flight regimes. These innovations facilitate versatile propulsion solutions for aerospace applications, notably improving payload capacity and mission flexibility.

Future Trends in Aerospace Propulsion

Future trends in aerospace propulsion emphasize the integration of air-breathing engines with advanced rocket technology to enhance efficiency and reduce emissions. Developments in combined cycle engines, such as SABRE and turbine-based combined cycle (TBCC) systems, aim to enable hypersonic travel by transitioning smoothly from atmospheric oxygen intake to onboard oxidizer combustion. These innovations promise to revolutionize space access by lowering launch costs and increasing reusability through hybrid propulsion architectures.

Propulsive efficiency

Air-breathing engines achieve higher propulsive efficiency than rocket engines by utilizing atmospheric oxygen for combustion, reducing onboard oxidizer weight and improving thrust-to-fuel consumption ratios at subsonic and supersonic speeds.

Thrust-to-weight ratio

Air-breathing engines typically achieve lower thrust-to-weight ratios than rocket engines, with values around 5-10 compared to rocket engines' 50-100, due to their reliance on atmospheric oxygen which reduces onboard oxidizer weight.

Specific impulse (Isp)

Air-breathing engines achieve higher Specific Impulse (Isp) than rocket engines by using atmospheric oxygen for combustion, reducing onboard oxidizer weight and increasing fuel efficiency.

Ramjet

Ramjet engines achieve efficient high-speed air-breathing propulsion by compressing incoming air without moving parts, unlike rocket engines that carry onboard oxidizers to operate in space.

Scramjet

Scramjet engines optimize hypersonic air-breathing propulsion by efficiently compressing and combusting atmospheric oxygen at speeds above Mach 5, contrasting with rocket engines that carry onboard oxidizers for operation in space.

Oxidizer independence

Air-breathing engines extract atmospheric oxygen for combustion, making them oxidizer-independent, whereas rocket engines carry onboard oxidizers, enabling operation in oxygen-free environments like space.

Bypass ratio

Air-breathing engines have high bypass ratios that improve fuel efficiency by utilizing atmospheric oxygen, whereas rocket engines have a bypass ratio of zero as they carry both fuel and oxidizer for operation in space.

Staging (propulsion staging)

Air-breathing engines enable initial flight stages by utilizing atmospheric oxygen for fuel combustion, reducing onboard oxidizer mass, while rocket engines provide higher thrust and operate independently of the atmosphere during upper stages, making propulsion staging critical for efficient orbital insertion.

Atmospheric pressure adaptation

Air-breathing engines optimize performance by utilizing atmospheric oxygen and adjusting to varying atmospheric pressure, whereas rocket engines carry oxidizers onboard, enabling consistent thrust independent of atmospheric pressure fluctuations.

Turbojet

Turbojet engines operate by compressing and combusting atmospheric air to generate thrust efficiently at subsonic and transonic speeds, whereas rocket engines carry both fuel and oxidizer, enabling propulsion in the vacuum of space but with higher fuel consumption and complexity.

air-breathing engines vs rocket engines Infographic

njnir.com

njnir.com