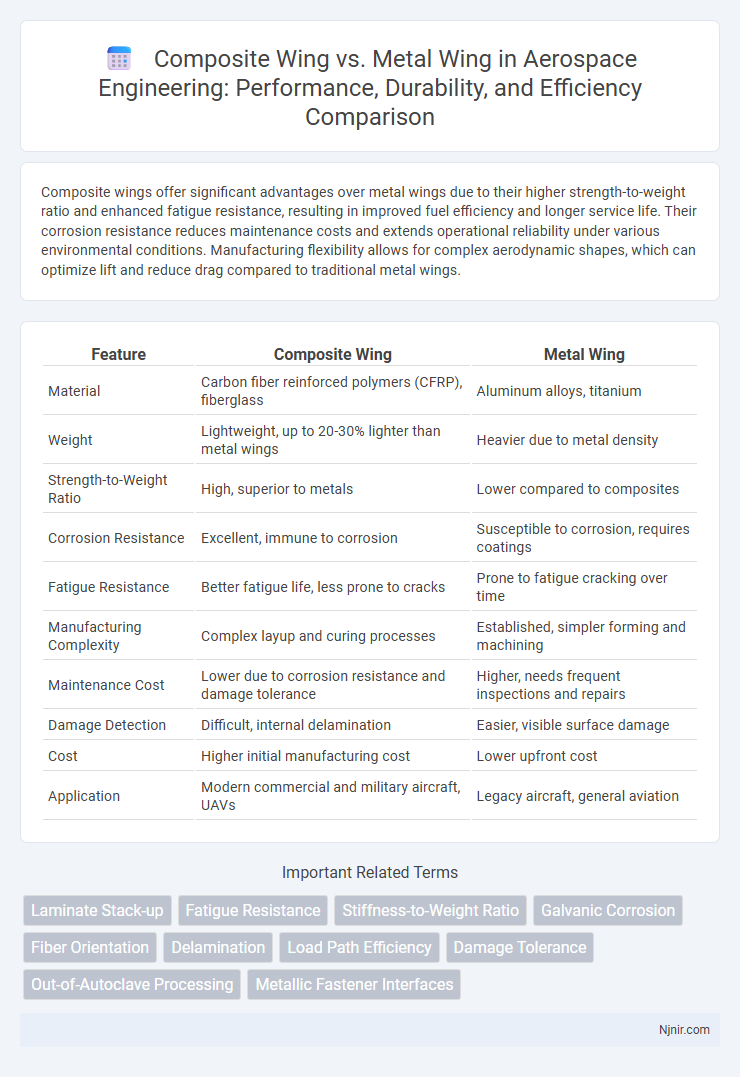

Composite wings offer significant advantages over metal wings due to their higher strength-to-weight ratio and enhanced fatigue resistance, resulting in improved fuel efficiency and longer service life. Their corrosion resistance reduces maintenance costs and extends operational reliability under various environmental conditions. Manufacturing flexibility allows for complex aerodynamic shapes, which can optimize lift and reduce drag compared to traditional metal wings.

Table of Comparison

| Feature | Composite Wing | Metal Wing |

|---|---|---|

| Material | Carbon fiber reinforced polymers (CFRP), fiberglass | Aluminum alloys, titanium |

| Weight | Lightweight, up to 20-30% lighter than metal wings | Heavier due to metal density |

| Strength-to-Weight Ratio | High, superior to metals | Lower compared to composites |

| Corrosion Resistance | Excellent, immune to corrosion | Susceptible to corrosion, requires coatings |

| Fatigue Resistance | Better fatigue life, less prone to cracks | Prone to fatigue cracking over time |

| Manufacturing Complexity | Complex layup and curing processes | Established, simpler forming and machining |

| Maintenance Cost | Lower due to corrosion resistance and damage tolerance | Higher, needs frequent inspections and repairs |

| Damage Detection | Difficult, internal delamination | Easier, visible surface damage |

| Cost | Higher initial manufacturing cost | Lower upfront cost |

| Application | Modern commercial and military aircraft, UAVs | Legacy aircraft, general aviation |

Introduction to Wing Materials in Aerospace Engineering

Composite wings, primarily made from carbon fiber reinforced polymers, offer superior strength-to-weight ratios and enhanced fatigue resistance compared to traditional metal wings, predominantly constructed from aluminum alloys. These advanced composite materials enable significant weight reduction, improved aerodynamic efficiency, and increased corrosion resistance, essential for modern aerospace engineering. Metal wings, while historically dominant due to their ease of manufacturing and repair, present limitations in weight and susceptibility to corrosion, motivating the industry's shift towards composite technology for next-generation aircraft design.

Evolution of Wing Design: From Metal to Composite

The evolution of wing design from metal to composite materials has revolutionized aerospace engineering by significantly enhancing strength-to-weight ratios and fatigue resistance. Composite wings, made primarily from carbon fiber reinforced polymers, offer superior aerodynamic efficiency and corrosion resistance compared to traditional aluminum wings. This transition has enabled the development of lighter, more fuel-efficient aircraft with improved performance and reduced maintenance costs.

Structural Strength and Weight Comparison

Composite wings exhibit superior structural strength-to-weight ratios compared to traditional metal wings, enabling enhanced load-bearing capacity while reducing overall aircraft weight. The use of advanced carbon fiber reinforced polymers allows composite wings to resist fatigue and corrosion better than aluminum alloys commonly used in metal wings. Lightweight composite structures contribute to improved fuel efficiency and increased payload capacity, making them a preferred choice for modern aerospace applications.

Durability and Fatigue Resistance

Composite wings exhibit superior durability and fatigue resistance compared to traditional metal wings due to their resistance to corrosion and ability to distribute stress more evenly across materials like carbon fiber reinforced polymers. Metal wings, typically made from aluminum alloys, are prone to stress corrosion cracking and fatigue cracking over time, requiring more frequent inspections and maintenance. The enhanced fatigue performance of composite materials contributes to longer service life and reduced lifecycle costs in modern aircraft design.

Manufacturing Processes and Costs

Composite wings utilize advanced fabrication techniques such as automated fiber placement and resin transfer molding, significantly reducing part count and assembly time compared to traditional metal wings, which require complex machining and riveting processes. The raw material costs for composites are higher, but lower labor and maintenance expenses can offset these initial investments over the aircraft lifecycle. Metal wings involve well-established manufacturing infrastructure and lower upfront material costs but incur higher labor-intensive assembly and corrosion prevention expenses, impacting overall production efficiency and long-term operational costs.

Aerodynamic Performance and Design Flexibility

Composite wings offer superior aerodynamic performance due to their ability to be molded into complex, optimized shapes that reduce drag and improve lift-to-drag ratio compared to traditional metal wings. The inherent design flexibility of composite materials allows for weight reduction and integration of advanced wing features like winglets and morphing surfaces, enhancing fuel efficiency and maneuverability. Metal wings, while structurally reliable and easier to inspect, are limited by manufacturing constraints that restrict aerodynamic optimization and result in heavier structures.

Maintenance, Inspection, and Repair Considerations

Composite wings offer reduced maintenance due to corrosion resistance and fatigue durability compared to metal wings, which require frequent corrosion checks and structural inspections. Inspection of composite wings involves advanced non-destructive testing methods such as ultrasonic and thermography techniques, whereas metal wings primarily rely on visual and dye penetrant inspections. Repairing composite wings demands specialized materials and expertise to restore structural integrity, while metal wing repairs are generally more straightforward with established riveting and welding processes.

Environmental Impact and Sustainability

Composite wings reduce environmental impact by offering lighter structures, which enhance fuel efficiency and decrease carbon emissions during aircraft operation. Unlike traditional metal wings, composites require less energy-intensive manufacturing processes and generate less waste, contributing to greater sustainability. Additionally, the corrosion resistance and durability of composite materials extend aircraft lifespan, reducing resource consumption and environmental footprint over time.

Case Studies: Aircraft Utilizing Composite vs Metal Wings

The Boeing 787 Dreamliner exemplifies successful use of composite wings, featuring 50% composite materials that reduce weight and improve fuel efficiency compared to traditional metal wings. In contrast, the Boeing 737, constructed primarily with metal wings, demonstrates durability and lower manufacturing costs but suffers from higher fuel consumption and maintenance needs. Case studies highlight that composite wings provide superior aerodynamic performance and corrosion resistance, while metal wings remain favored for cost-effective manufacturing in short-range aircraft.

Future Trends in Wing Material Technologies

Composite wings dominate future trends in aerospace due to their superior strength-to-weight ratio and corrosion resistance, enabling enhanced fuel efficiency and longer airframe life. Advanced materials like carbon fiber-reinforced polymers (CFRP) and innovative manufacturing techniques, such as automated fiber placement, drive significant reductions in production costs and structural weight compared to traditional metal wings. Emerging hybrid designs integrating composites with lightweight metals offer optimized performance, balancing durability and flexibility while meeting stringent environmental regulations and sustainability goals.

Laminate Stack-up

Composite wing laminate stack-up enables precise fiber orientation and tailored thickness for optimal strength-to-weight ratio, surpassing traditional metal wing structures with uniform material properties.

Fatigue Resistance

Composite wings exhibit superior fatigue resistance compared to metal wings due to their enhanced ability to distribute stress and resist crack propagation under cyclic loading.

Stiffness-to-Weight Ratio

Composite wings offer a significantly higher stiffness-to-weight ratio than metal wings, enhancing aircraft performance by reducing weight while maintaining structural rigidity.

Galvanic Corrosion

Composite wings resist galvanic corrosion better than metal wings due to their non-metallic matrix, reducing the risk of electrochemical reactions between dissimilar metals in aircraft structures.

Fiber Orientation

Composite wings feature customizable fiber orientation to optimize strength and stiffness along load paths, whereas metal wings rely on isotropic material properties with uniform strength in all directions.

Delamination

Composite wings have a higher risk of delamination under stress compared to metal wings, which typically exhibit more uniform deformation and lower susceptibility to internal layer separation.

Load Path Efficiency

Composite wings offer superior load path efficiency compared to metal wings due to their ability to tailor fiber orientations for optimal stress distribution and reduced weight.

Damage Tolerance

Composite wings exhibit superior damage tolerance compared to metal wings due to their ability to resist crack propagation and maintain structural integrity under impact and fatigue conditions.

Out-of-Autoclave Processing

Out-of-autoclave processing enables composite wings to be manufactured with reduced weight and improved fatigue resistance compared to traditional metal wings, enhancing aerospace efficiency and performance.

Metallic Fastener Interfaces

Composite wings exhibit reduced corrosion and fatigue at metallic fastener interfaces compared to conventional metal wings, enhancing longevity and maintenance efficiency.

Composite Wing vs Metal Wing Infographic

njnir.com

njnir.com