Propellant depots enable spacecraft to refuel in orbit, reducing launch mass and increasing mission flexibility for deep-space exploration. In-situ resource utilization (ISRU) involves harvesting and processing local materials on planetary surfaces to produce fuel, which minimizes dependence on Earth resupply and lowers mission costs. Combining both strategies can optimize propellant availability and enhance the sustainability of long-duration aerospace missions.

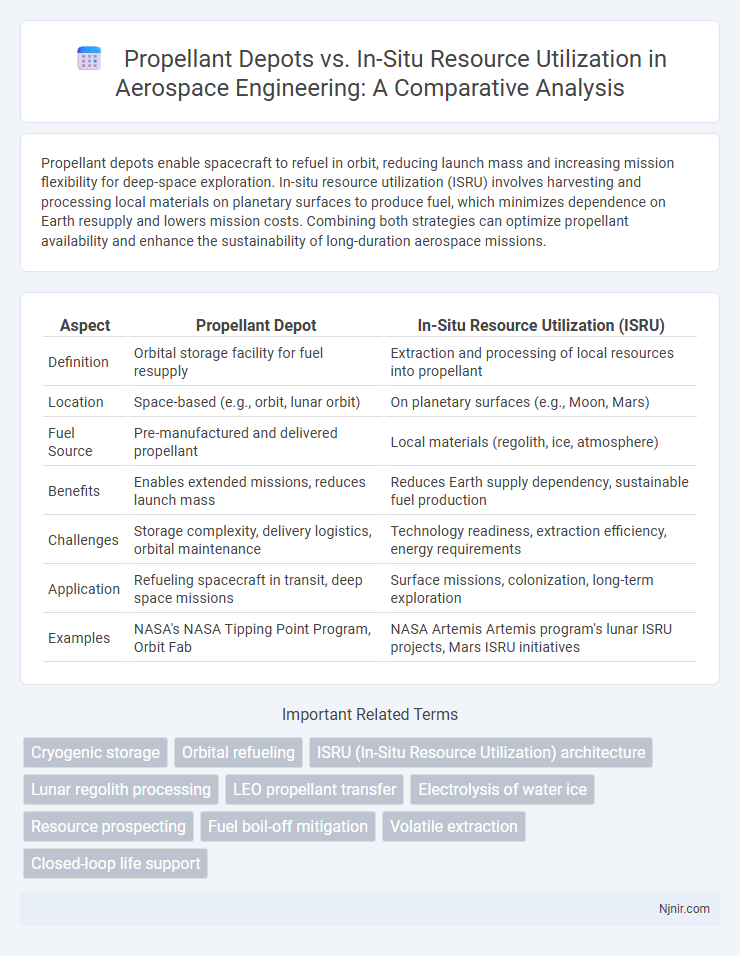

Table of Comparison

| Aspect | Propellant Depot | In-Situ Resource Utilization (ISRU) |

|---|---|---|

| Definition | Orbital storage facility for fuel resupply | Extraction and processing of local resources into propellant |

| Location | Space-based (e.g., orbit, lunar orbit) | On planetary surfaces (e.g., Moon, Mars) |

| Fuel Source | Pre-manufactured and delivered propellant | Local materials (regolith, ice, atmosphere) |

| Benefits | Enables extended missions, reduces launch mass | Reduces Earth supply dependency, sustainable fuel production |

| Challenges | Storage complexity, delivery logistics, orbital maintenance | Technology readiness, extraction efficiency, energy requirements |

| Application | Refueling spacecraft in transit, deep space missions | Surface missions, colonization, long-term exploration |

| Examples | NASA's NASA Tipping Point Program, Orbit Fab | NASA Artemis Artemis program's lunar ISRU projects, Mars ISRU initiatives |

Introduction to Propellant Depot and In-Situ Resource Utilization

Propellant depots serve as orbital refueling stations, enabling spacecraft to replenish fuel and extend mission ranges without launching fully fueled from Earth. In-situ resource utilization (ISRU) involves harvesting and converting local materials from celestial bodies, such as the Moon or Mars, into propellant, reducing dependency on Earth-supplied fuel. Both strategies aim to lower launch mass, cut costs, and support sustainable deep-space exploration by optimizing fuel availability beyond Earth.

Defining Propellant Depots: Concepts and Applications

Propellant depots are orbital storage facilities designed to store and supply rocket propellant to spacecraft during missions, enabling extended reach and reusability in space exploration. These depots reduce the need for heavy fuel loads on launch vehicles by providing refueling options in low Earth orbit, lunar orbit, or deep space, thereby enhancing mission flexibility and cost-efficiency. Applications of propellant depots include supporting crewed Mars missions, lunar bases, and orbital servicing, leveraging existing technologies to facilitate sustainable space logistics.

In-Situ Resource Utilization: Principles and Techniques

In-situ resource utilization (ISRU) involves harvesting and processing local materials on celestial bodies to produce propellants, reducing the need to transport fuel from Earth and thereby lowering mission costs. Techniques include extracting water ice from lunar or Martian soil, electrolysis to generate hydrogen and oxygen for rocket fuel, and converting atmospheric CO2 into methane using the Sabatier process. ISRU principles focus on maximizing resource availability, minimizing energy consumption, and integrating with habitat and propulsion systems to support sustainable space exploration.

Advantages of Propellant Depot Systems

Propellant depot systems offer strategic advantages by enabling spacecraft to refuel in orbit, significantly reducing launch mass and costs associated with carrying full fuel loads from Earth. This approach increases mission flexibility, supports longer-duration missions, and facilitates deep-space exploration through scalable fuel storage and distribution infrastructure. By centralizing fuel resources, propellant depots enhance logistics efficiency and reduce reliance on complex in-situ resource extraction technologies.

Benefits of In-Situ Resource Utilization for Space Missions

In-situ resource utilization (ISRU) enables spacecraft to extract and use local materials such as lunar regolith or Martian water ice, reducing the need to launch massive amounts of propellant from Earth. This approach significantly decreases mission costs by minimizing payload weight, enabling longer and more sustainable space missions with enhanced autonomy. ISRU supports the establishment of permanent outposts and refueling stations, facilitating deep space exploration and enabling human presence on the Moon, Mars, and beyond.

Comparative Analysis: Propellant Depot vs ISRU

Propellant depots provide on-orbit refueling infrastructure using Earth-supplied propellants, enabling extended mission durations and reduced launch mass for interplanetary travel. In-situ resource utilization (ISRU) technology extracts and processes local materials, such as lunar regolith or Martian ice, to produce fuel directly at the destination, minimizing dependence on Earth launches. Comparative analysis reveals propellant depots offer immediate scalability and infrastructure reuse, while ISRU promises long-term sustainability and cost reduction but faces significant technological and operational challenges.

Technology Challenges and Solutions

Propellant depots face technological challenges including long-duration cryogenic propellant storage, boil-off mitigation, and efficient refueling systems in microgravity environments. In-situ resource utilization (ISRU) grapples with extracting and processing local materials on planetary surfaces, requiring robust mining, regolith processing, and life support integration technologies under harsh environmental conditions. Solutions for propellant depots emphasize advanced insulation materials, zero-boil-off refrigeration, and automated docking interfaces, while ISRU developments focus on modular processing units, autonomous robotics, and electrochemical reduction techniques to maximize resource extraction and fuel synthesis efficiency.

Economic Implications and Cost-Benefit Analysis

Propellant depots, involving the storage and resupply of pre-manufactured fuel in space, demand substantial initial investment in transportation and infrastructure but enable cost reductions through fuel consolidation and reuse for multiple missions. In-situ resource utilization (ISRU) leverages local materials, like lunar regolith or Martian ice, to produce propellant directly at the destination, significantly minimizing launch mass and reducing dependency on Earth-based supply chains, thus lowering long-term mission expenses. Economic analyses reveal ISRU's high upfront technology development costs contrasted with potential exponential savings over extended exploration timelines, making its cost-benefit profile favorable for sustained deep-space missions beyond low Earth orbit.

Impact on Long-Duration and Deep Space Exploration

Propellant depots enable spacecraft to refuel in orbit, significantly extending mission duration and reducing launch mass for long-duration and deep space exploration. In-situ resource utilization (ISRU) allows extraction and processing of local materials on planetary surfaces, supporting sustained exploration by minimizing dependence on Earth-supplied resources. Combining propellant depots with ISRU technologies enhances mission flexibility, cost-efficiency, and viability for deep space habitats and crewed Mars missions.

Future Prospects and Integration Strategies

Propellant depots offer strategic refueling points in orbit, reducing launch mass and enabling flexible mission planning, while in-situ resource utilization (ISRU) focuses on extracting and processing local materials on the Moon or Mars to produce fuel, significantly lowering Earth dependency. Future prospects involve integrating depots with ISRU by transporting locally produced propellant to orbital storage, enhancing sustainability and extended mission capacities. Combining these technologies can optimize supply chains for deep-space exploration, cutting costs and enabling continuous human presence beyond Earth.

Cryogenic storage

Cryogenic storage challenges in propellant depots include boil-off and insulation, whereas in-situ resource utilization (ISRU) minimizes these issues by producing fuel on-site, reducing long-term storage requirements.

Orbital refueling

Orbital refueling through propellant depots offers immediate fuel availability and logistical flexibility, while in-situ resource utilization reduces launch mass by extracting and processing local space resources for sustainable long-term missions.

ISRU (In-Situ Resource Utilization) architecture

ISRU architecture prioritizes extracting and processing local resources on celestial bodies to produce propellant, significantly reducing the need for costly Earth-launched propellant depots and enabling sustainable deep space exploration.

Lunar regolith processing

Lunar regolith processing for propellant depots enables in-situ resource utilization by extracting oxygen and hydrogen, reducing Earth launch mass and supporting sustainable lunar missions.

LEO propellant transfer

Propellant depots in LEO enable efficient refueling and extended mission duration by storing and transferring fuel, while in-situ resource utilization minimizes launch mass by extracting propellant from extraterrestrial materials but faces technical challenges for reliable LEO resupply.

Electrolysis of water ice

Electrolysis of water ice extracted through in-situ resource utilization offers a sustainable method for producing hydrogen and oxygen propellants directly on extraterrestrial surfaces, reducing reliance on costly propellant depots transported from Earth.

Resource prospecting

Propellant depots require pre-positioned fuel storage in orbit, whereas in-situ resource utilization relies on advanced resource prospecting techniques to extract and process local materials on celestial bodies for sustainable refueling.

Fuel boil-off mitigation

Propellant depots use advanced cryogenic storage technologies to reduce fuel boil-off, while in-situ resource utilization minimizes boil-off risks by producing fuel directly on-site, eliminating long-term storage challenges.

Volatile extraction

Propellant depots store transported volatiles for spacecraft refueling, while in-situ resource utilization directly extracts volatiles from extraterrestrial environments like lunar regolith or Martian ice to enable sustainable space missions.

Closed-loop life support

Closed-loop life support systems in propellant depots enable efficient resource recycling for spacecraft refueling, whereas in-situ resource utilization relies on extracting and processing local materials to sustain long-term missions with minimal Earth resupply.

Propellant depot vs In-situ resource utilization Infographic

njnir.com

njnir.com