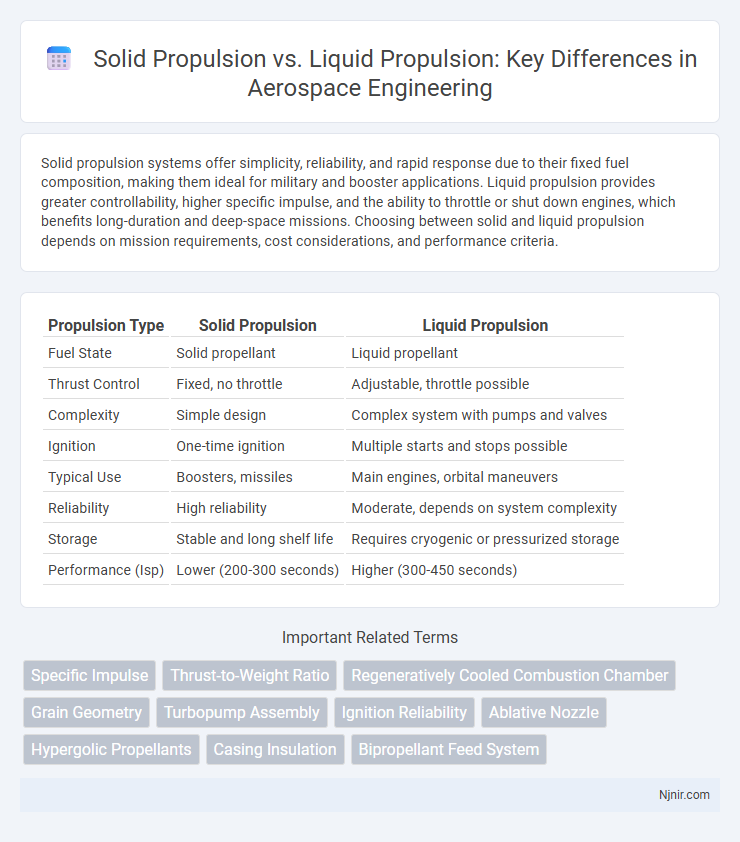

Solid propulsion systems offer simplicity, reliability, and rapid response due to their fixed fuel composition, making them ideal for military and booster applications. Liquid propulsion provides greater controllability, higher specific impulse, and the ability to throttle or shut down engines, which benefits long-duration and deep-space missions. Choosing between solid and liquid propulsion depends on mission requirements, cost considerations, and performance criteria.

Table of Comparison

| Propulsion Type | Solid Propulsion | Liquid Propulsion |

|---|---|---|

| Fuel State | Solid propellant | Liquid propellant |

| Thrust Control | Fixed, no throttle | Adjustable, throttle possible |

| Complexity | Simple design | Complex system with pumps and valves |

| Ignition | One-time ignition | Multiple starts and stops possible |

| Typical Use | Boosters, missiles | Main engines, orbital maneuvers |

| Reliability | High reliability | Moderate, depends on system complexity |

| Storage | Stable and long shelf life | Requires cryogenic or pressurized storage |

| Performance (Isp) | Lower (200-300 seconds) | Higher (300-450 seconds) |

Introduction to Rocket Propulsion Systems

Solid propulsion systems utilize pre-packed solid propellants that offer simplicity, reliability, and high thrust, commonly used in military missiles and booster stages. Liquid propulsion systems employ separate fuel and oxidizer tanks with complex plumbing, enabling throttling, restart capability, and higher specific impulse, favored in orbital launch vehicles. The choice between solid and liquid propulsion depends on mission requirements, performance needs, and operational flexibility.

Fundamentals of Solid Propulsion Technology

Solid propulsion technology relies on a homogeneous mixture of fuel and oxidizer in a solid state, characterized by a simple design with fewer moving parts and high reliability under extreme conditions. The fundamental process involves the combustion of a solid propellant grain, which produces high-pressure gases that are expelled through a nozzle to generate thrust. Compared to liquid propulsion, solid propulsion systems offer faster response times, greater storage stability, and simplified manufacturing, making them ideal for tactical missiles and booster stages.

Fundamentals of Liquid Propulsion Technology

Liquid propulsion technology relies on the controlled combustion of liquid propellants, typically a combination of liquid fuel and oxidizer stored in separate tanks, enabling precise thrust modulation and engine restart capabilities. This system employs turbopumps to deliver propellants under high pressure into the combustion chamber, ensuring efficient mixing and combustion for optimized performance. Compared to solid propulsion, liquid propulsion offers superior specific impulse and flexibility, essential for orbital insertion and deep space missions.

Thrust Generation: Solid vs Liquid Propulsion

Solid propulsion generates thrust through the rapid combustion of a pre-mixed solid propellant, producing high-pressure gases that are expelled to create thrust with a fixed burn rate. Liquid propulsion uses separate fuel and oxidizer tanks, mixing and combusting them in a combustion chamber, allowing precise control over thrust magnitude and duration. Liquid engines offer variable thrust and throttling capabilities, while solid engines provide simplicity and high thrust-to-weight ratios but lack throttle control.

Propellant Storage and Handling Considerations

Solid propulsion systems store propellant in a stable, compact, and pre-mixed solid grain, eliminating the need for complex storage infrastructure but limiting control over thrust once ignited. Liquid propulsion utilizes separate tanks for fuel and oxidizer, requiring cryogenic or pressurized storage systems to maintain propellant stability, which introduces challenges in handling volatile liquids and ensuring leak-free transfer. The trade-off between solid's simplicity and liquid's controllability heavily influences vehicle design, operational logistics, and safety protocols.

Performance Metrics: Specific Impulse and Efficiency

Solid propulsion systems generally offer lower specific impulse, typically between 180 to 260 seconds, resulting in reduced fuel efficiency compared to liquid propulsion, which can achieve specific impulses ranging from 300 to 450 seconds or higher. Liquid propulsion allows for more precise thrust control and higher combustion efficiency, enhancing overall performance metrics in terms of specific impulse and payload capacity. The higher efficiency of liquid engines contributes to better fuel utilization and mission adaptability, making them preferable for complex orbital maneuvers.

Reliability and Safety Comparisons

Solid propulsion systems offer higher reliability due to their simpler design and fewer moving parts, minimizing potential failure points during rocket operation. Liquid propulsion provides greater safety control through throttleability and engine shutdown capabilities, allowing precise management of thrust and immediate response to anomalies. Reliability in solid propulsion favors robustness, while liquid propulsion emphasizes operational safety and adaptability in critical flight scenarios.

Operational Flexibility and Mission Profiles

Solid propulsion systems offer rapid launch readiness and simplicity, making them ideal for short-duration missions and tactical applications with fixed trajectories. Liquid propulsion provides superior operational flexibility through throttle control, shutdown, and restart capabilities, enabling precise orbit insertions, variable thrust profiles, and complex mission requirements. Missions demanding high accuracy, multiple burns, or extended thrust phases benefit significantly from liquid propulsion's adaptability and controllability.

Cost and Manufacturing Implications

Solid propulsion systems offer lower manufacturing costs due to simpler design, fewer moving parts, and ease of mass production, making them ideal for cost-sensitive applications. Liquid propulsion systems involve higher manufacturing complexity with precision components, intricate plumbing, and pumps, resulting in increased production expenses. Cost implications also extend to maintenance and storage, where solids have advantages in storability while liquids require elaborate handling and infrastructure.

Future Trends in Propulsion Systems

Future trends in propulsion systems emphasize hybrid technologies combining the high thrust of solid propulsion with the precise controllability of liquid propulsion to enhance efficiency and adaptability in space missions. Advancements in green propellants and additive manufacturing are driving innovations in liquid engines, aiming to reduce environmental impact and production costs. Emerging research on plasma and electric propulsion integrates with traditional systems to enable longer-duration missions with improved thrust-to-weight ratios and fuel economy.

Specific Impulse

Liquid propulsion systems typically achieve higher specific impulse values, ranging from 300 to 450 seconds, compared to solid propulsion systems which usually have specific impulses between 250 and 300 seconds, making liquid engines more efficient for sustained thrust applications.

Thrust-to-Weight Ratio

Solid propulsion systems typically have a higher thrust-to-weight ratio than liquid propulsion systems, making them more efficient for rapid acceleration and launch vehicle boosters.

Regeneratively Cooled Combustion Chamber

Regeneratively cooled combustion chambers in liquid propulsion systems use propellant flow to absorb heat, enhancing thermal management and performance, whereas solid propulsion lacks this cooling method, limiting heat dissipation and chamber lifespan.

Grain Geometry

Grain geometry in solid propulsion directly influences burn rate and thrust profile, whereas liquid propulsion relies on injector design and flow rates, making grain structure irrelevant.

Turbopump Assembly

Turbopump assemblies in liquid propulsion systems enhance fuel flow efficiency and engine performance, contrasting with solid propulsion's fixed-thrust design lacking such complex components.

Ignition Reliability

Solid propulsion offers higher ignition reliability due to its simple design and stored propellant, whereas liquid propulsion systems require complex ignition mechanisms that may introduce ignition delays or failures.

Ablative Nozzle

Ablative nozzles in solid propulsion systems provide efficient thermal protection by eroding material to dissipate heat, while liquid propulsion typically uses regenerative cooling for nozzle temperature management.

Hypergolic Propellants

Hypergolic propellants ignite spontaneously on contact, making liquid propulsion systems more controllable and restartable compared to the simpler, non-restartable solid propulsion systems.

Casing Insulation

Solid propulsion casings require robust thermal insulation to withstand high combustion temperatures and prevent structural damage, whereas liquid propulsion casings benefit from regenerative cooling systems that reduce the need for heavy insulation layers.

Bipropellant Feed System

Bipropellant feed systems in liquid propulsion enable precise control and higher efficiency compared to the fixed-thrust, simpler design of solid propulsion systems.

Solid propulsion vs Liquid propulsion Infographic

njnir.com

njnir.com