The space elevator offers a revolutionary approach to accessing orbit by providing a continuous, cost-effective transportation system, reducing the dependence on expensive rocket launches. Reusable rockets, while significantly lowering launch costs through refurbishing and multiple uses, still face limitations in payload capacity and turnaround time compared to the scalability of space elevator technology. Advancements in materials science and engineering are critical to overcoming the challenges of constructing a space elevator, potentially enabling a transformative shift in space transportation infrastructure.

Table of Comparison

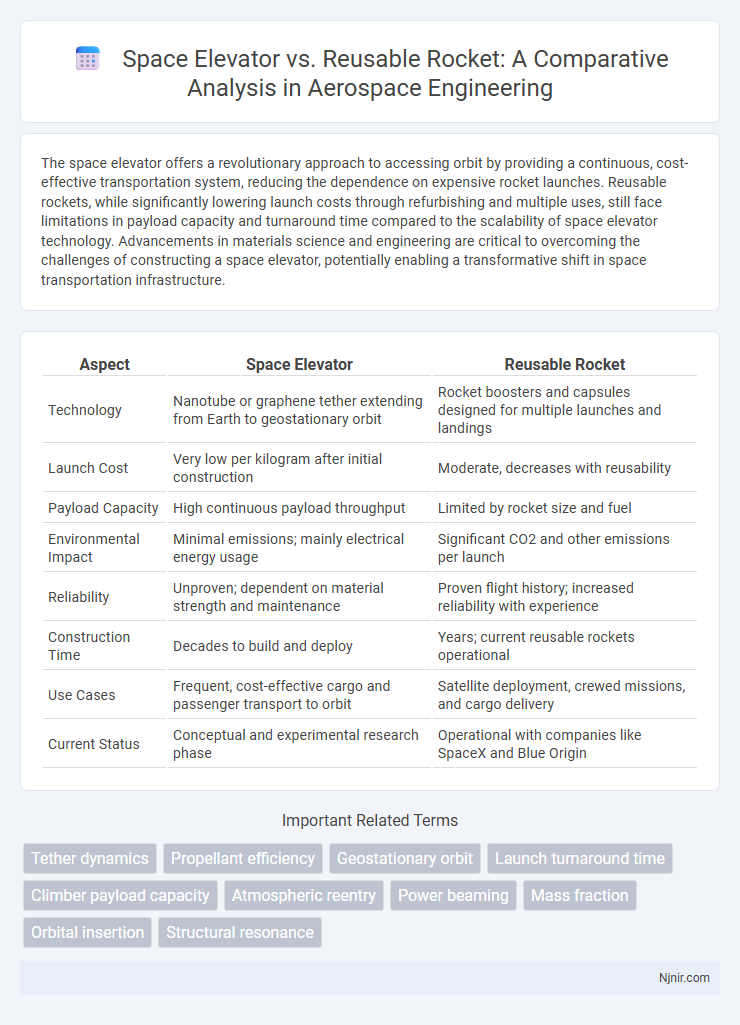

| Aspect | Space Elevator | Reusable Rocket |

|---|---|---|

| Technology | Nanotube or graphene tether extending from Earth to geostationary orbit | Rocket boosters and capsules designed for multiple launches and landings |

| Launch Cost | Very low per kilogram after initial construction | Moderate, decreases with reusability |

| Payload Capacity | High continuous payload throughput | Limited by rocket size and fuel |

| Environmental Impact | Minimal emissions; mainly electrical energy usage | Significant CO2 and other emissions per launch |

| Reliability | Unproven; dependent on material strength and maintenance | Proven flight history; increased reliability with experience |

| Construction Time | Decades to build and deploy | Years; current reusable rockets operational |

| Use Cases | Frequent, cost-effective cargo and passenger transport to orbit | Satellite deployment, crewed missions, and cargo delivery |

| Current Status | Conceptual and experimental research phase | Operational with companies like SpaceX and Blue Origin |

Introduction to Space Elevators and Reusable Rockets

Space elevators are conceptual structures designed to transport materials from Earth's surface directly into orbit using a tether anchored to the ground and extending beyond geostationary orbit. Reusable rockets, developed by companies like SpaceX and Blue Origin, are launch vehicles engineered to return intact after delivering payloads to space, significantly reducing launch costs. Both technologies aim to improve space access but differ fundamentally in approach, with space elevators focusing on continuous tether-based transport and reusable rockets relying on vertical takeoff and landing.

Historical Background and Development

The concept of the space elevator dates back to 1895, when Russian scientist Konstantin Tsiolkovsky proposed a tower reaching geostationary orbit to revolutionize space travel. In contrast, reusable rockets gained prominence in the late 20th century, with SpaceX's Falcon 9 achieving the first successful vertical landing and reuse in 2015, marking a significant milestone in reducing launch costs. While the space elevator remains a theoretical project hindered by material science challenges, reusable rocket technology has rapidly evolved into an operational advancement transforming the aerospace industry.

Core Engineering Principles

Space elevators utilize tensile strength and materials science to create a stable, geostationary tether capable of supporting climbers against Earth's gravity and centrifugal force. Reusable rockets rely on propulsion technology, thermodynamics, and structural engineering to withstand high stress during launch, re-entry, and landing, enabling multiple flights and cost reduction. Both systems emphasize energy efficiency and durability, but space elevators prioritize continuous load-bearing capacity, whereas reusable rockets focus on rapid turnaround and aerodynamic control.

Material Requirements and Innovations

Space elevators demand ultra-strong materials such as carbon nanotubes or graphene to withstand immense tensile forces and maintain structural integrity over tens of thousands of kilometers. Reusable rockets prioritize advancements in lightweight composite materials and heat-resistant alloys to endure multiple launches and re-entries. Innovations in nanotechnology and material science are critical for space elevators, while reusable rockets benefit from breakthroughs in propulsion systems and thermal protection materials.

Launch and Operational Efficiencies

A space elevator offers significantly lower launch costs by eliminating the need for fuel-heavy rocket launches, enabling continuous and efficient payload delivery to orbit through a tethered climber system. Reusable rockets demand substantial maintenance and refurbishment between flights, increasing operational expenses and turnaround time despite advancements in rapid reusability. The space elevator's ability to provide frequent, reliable access to space without the volatility of fuel consumption enhances long-term operational efficiencies compared to the cyclical wear and performance variability inherent in reusable rocket systems.

Cost Analysis and Economic Feasibility

Space elevators present a high initial capital expenditure due to the need for advanced carbon nanotube tether materials and complex infrastructure but promise drastically lower per-launch costs by eliminating fuel expenses and reusable components' refurbishments. Reusable rockets like SpaceX's Falcon 9 reduce costs by reusing expensive rocket boosters, cutting launch prices to approximately $2,700 per kilogram to low Earth orbit, yet still face expenses related to refurbishment, fuel, and durability limits. Economic feasibility favors reusable rockets currently due to established technology and incremental cost savings, while space elevators require breakthroughs in material science and massive upfront investment to become cost-effective for large-scale, long-term space transport.

Environmental Impact Comparison

Space elevators offer a substantially lower environmental footprint compared to reusable rockets by eliminating the need for high-propellant burns, which produce significant greenhouse gas emissions and atmospheric pollution. Reusable rockets, despite reducing launch waste through multiple uses, still rely on combustion of rocket-grade fuels like RP-1 or liquid hydrogen, releasing CO2, water vapor, and black carbon into the upper atmosphere, contributing to ozone depletion and climate change. The continuous use of space elevators powered by clean electricity could drastically reduce airborne contaminants and combustion byproducts tied to traditional rocket launches.

Safety and Risk Assessment

Space elevators present a lower risk of catastrophic failure compared to reusable rockets due to the absence of high-speed launches and atmospheric re-entry hazards. Reusable rockets face significant safety challenges from engine malfunctions, rapid velocity changes, and potential debris during takeoff and landing phases. The long-term structural integrity and material durability of space elevators remain critical safety concerns, requiring advanced nanomaterials like carbon nanotubes to mitigate risk.

Potential Applications and Use Cases

Space elevators offer transformative potential for continuous, low-cost access to orbit, enabling large-scale cargo transport and space tourism with minimal fuel use. Reusable rockets provide rapid, flexible launch capabilities ideal for satellite deployment, crewed missions, and interplanetary travel, supporting diverse payloads and mission profiles. Combining space elevators' scalability with reusable rockets' versatility can revolutionize supply chains for lunar bases, asteroid mining, and deep space exploration.

Future Prospects and Roadmap

The future prospects of space elevators hinge on breakthroughs in carbon nanotube or graphene-based materials to achieve the necessary tensile strength for a tether extending tens of thousands of kilometers. Roadmaps for space elevators emphasize long-term research, substantial investment in materials science, and international collaboration to address engineering and safety challenges. In contrast, reusable rockets have demonstrated progressive advancements with multiple successful missions, clear commercialization paths, and incremental improvements planned within the next decade, making them a more immediate and viable solution for reducing launch costs and increasing cadence.

Tether dynamics

Space elevator tether dynamics involve continuous tensile stress management and material durability against micrometeoroids, contrasting with reusable rocket propulsion systems that rely on cyclic combustion and thermal resistance.

Propellant efficiency

Space elevators achieve superior propellant efficiency by eliminating the need for fuel to overcome Earth's gravity during launch, unlike reusable rockets that require significant propellant for each ascent and descent cycle.

Geostationary orbit

A space elevator offers continuous, low-energy transport to geostationary orbit, reducing launch costs and environmental impact compared to the fuel-intensive, limited-payload capacity of reusable rockets.

Launch turnaround time

Space elevators offer near-continuous launch capabilities with minimal turnaround time compared to reusable rockets, which require extensive refurbishment and inspection between launches.

Climber payload capacity

The space elevator's climber offers significantly higher payload capacity by lifting tons continuously without fuel limitations, whereas reusable rockets face strict payload restrictions due to fuel weight and launch dynamics.

Atmospheric reentry

Space elevators eliminate the challenges of atmospheric reentry faced by reusable rockets, which must withstand intense heat, friction, and structural stress during descent.

Power beaming

Power beaming enables continuous energy supply to space elevators, potentially reducing launch costs and increasing payload capacity compared to reusable rockets reliant on onboard fuel.

Mass fraction

Space elevators require a significantly lower mass fraction compared to reusable rockets, as they eliminate the need to carry propellant onboard for climbing, drastically improving payload efficiency.

Orbital insertion

Space elevators offer continuous, low-energy orbital insertion by lifting payloads along a tether, whereas reusable rockets rely on high-thrust propulsion stages to achieve rapid but fuel-intensive orbital insertion.

Structural resonance

Space elevators face critical challenges from structural resonance caused by atmospheric vibrations and orbital dynamics, whereas reusable rockets encounter dynamic loads primarily during launch and re-entry phases.

space elevator vs reusable rocket Infographic

njnir.com

njnir.com