Additive manufacturing builds aerospace components layer by layer, enabling complex geometries and reduced material waste compared to traditional subtractive manufacturing, which removes material from a solid block. This shift enhances design flexibility and shortens production cycles, crucial for lightweight structures and customized parts in aircraft and spacecraft. Cost efficiency and rapid prototyping make additive manufacturing increasingly preferred in aerospace engineering over conventional subtractive methods.

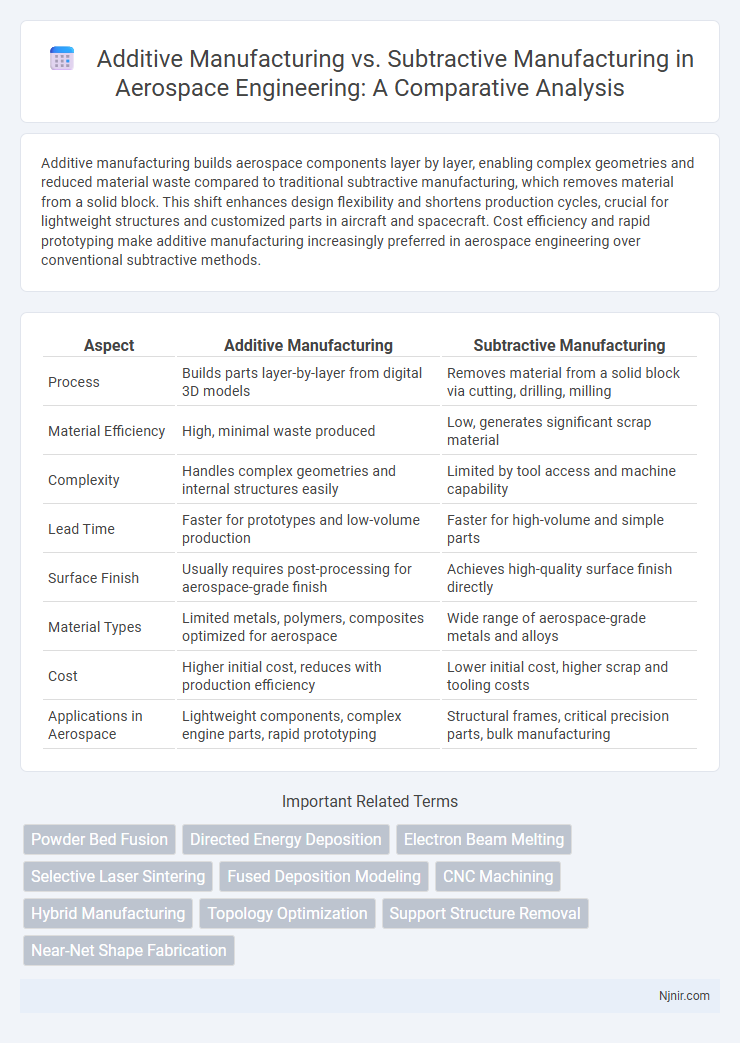

Table of Comparison

| Aspect | Additive Manufacturing | Subtractive Manufacturing |

|---|---|---|

| Process | Builds parts layer-by-layer from digital 3D models | Removes material from a solid block via cutting, drilling, milling |

| Material Efficiency | High, minimal waste produced | Low, generates significant scrap material |

| Complexity | Handles complex geometries and internal structures easily | Limited by tool access and machine capability |

| Lead Time | Faster for prototypes and low-volume production | Faster for high-volume and simple parts |

| Surface Finish | Usually requires post-processing for aerospace-grade finish | Achieves high-quality surface finish directly |

| Material Types | Limited metals, polymers, composites optimized for aerospace | Wide range of aerospace-grade metals and alloys |

| Cost | Higher initial cost, reduces with production efficiency | Lower initial cost, higher scrap and tooling costs |

| Applications in Aerospace | Lightweight components, complex engine parts, rapid prototyping | Structural frames, critical precision parts, bulk manufacturing |

Introduction to Manufacturing Processes in Aerospace

Additive manufacturing in aerospace builds components layer-by-layer from digital models, enabling complex geometries and lightweight structures that reduce material waste by up to 90%. Subtractive manufacturing involves removing material from bulk metal using CNC machining, ensuring high precision and surface finish crucial for critical aerospace parts like turbine blades. Combining both processes optimizes production efficiency, cost, and performance in aerospace manufacturing workflows.

Fundamentals of Additive Manufacturing

Additive manufacturing builds objects layer by layer from digital models using materials such as polymers, metals, or ceramics, enabling complex geometries and reduced waste. It contrasts with subtractive manufacturing, which removes material through machining or cutting processes. Key fundamentals include material deposition techniques like fused deposition modeling (FDM), selective laser sintering (SLS), and stereolithography (SLA), which allow precise control over shape, structure, and mechanical properties.

Principles of Subtractive Manufacturing

Subtractive manufacturing operates by removing material from a solid block through techniques such as milling, turning, or drilling to achieve the desired shape. This process relies on CNC machines to precisely cut away excess material based on digital designs, ensuring high accuracy and surface finish. Key principles include material removal rate, tool path optimization, and minimizing waste while maintaining structural integrity.

Material Compatibility and Selection

Additive manufacturing offers superior material compatibility by enabling the use of diverse materials such as thermoplastics, metals, ceramics, and composites, which are often challenging for subtractive methods due to tool wear or material brittleness. Subtractive manufacturing primarily relies on machinable materials like metals, plastics, and certain composites, with limitations imposed by tooling availability and material hardness. Material selection in additive processes allows for complex geometries and tailored properties by controlling layer deposition, whereas subtractive manufacturing focuses on removing material from solid blocks, restricting design freedom but ensuring uniform material properties.

Design Flexibility and Complexity

Additive manufacturing offers superior design flexibility by enabling the creation of intricate geometries and complex internal structures that are impossible or cost-prohibitive with subtractive methods. Subtractive manufacturing is limited by tool access and material removal constraints, restricting the complexity and customization of parts. The layer-by-layer approach of additive manufacturing supports highly customized, lightweight designs ideal for rapid prototyping and low-volume production.

Precision, Tolerance, and Surface Finish

Additive manufacturing excels in creating complex geometries with intricate internal features, offering layer-by-layer precision typically around +-0.1 mm, but often requires post-processing to improve surface finish and achieve tighter tolerances. Subtractive manufacturing delivers superior tolerance capabilities, often within microns (+-0.001 mm), and smoother surface finishes directly from the machining process, making it ideal for high-precision parts. The choice between additive and subtractive manufacturing depends on the balance between geometric complexity, required dimensional accuracy, and surface quality for the specific application.

Production Speed and Efficiency

Additive manufacturing often delivers faster prototyping and complex part production by building objects layer-by-layer with minimal material waste, enhancing efficiency for custom or small-batch runs. Subtractive manufacturing excels in high-volume production with rapid cycle times due to established machining processes like CNC milling, offering consistent precision but generating more material scrap. Choosing between these methods depends on application requirements, where additive is favored for design flexibility and waste reduction, while subtractive provides superior speed for mass production of standardized parts.

Cost Implications and Resource Utilization

Additive manufacturing reduces material waste by building components layer by layer, leading to lower raw material costs compared to subtractive manufacturing, which often removes excess material and generates significant scrap. Energy consumption in subtractive methods tends to be higher due to machining processes, whereas additive techniques can optimize energy use by precisely controlling deposition. Tool wear and maintenance expenses are significantly reduced in additive manufacturing, improving overall cost efficiency and resource utilization in production workflows.

Environmental Impact and Sustainability

Additive manufacturing significantly reduces material waste by building objects layer by layer, minimizing the use of raw materials compared to subtractive manufacturing, which often involves cutting away excess material. Energy consumption in additive processes is generally lower, contributing to a smaller carbon footprint and enhanced sustainability in production cycles. The ability to produce lightweight, complex parts with additive manufacturing supports fuel efficiency and resource conservation across industries such as aerospace and automotive.

Future Trends in Aerospace Manufacturing

Additive manufacturing in aerospace enables lightweight, complex structures that reduce material waste and improve fuel efficiency, driving innovation in components like turbine blades and structural brackets. Subtractive manufacturing remains essential for achieving tight tolerances and high surface finishes on critical aerospace parts, often complementing additive processes through hybrid manufacturing. Future trends highlight increased integration of AI-driven design optimization and automation, fostering faster production cycles and customized aerospace components with enhanced performance and sustainability.

Powder Bed Fusion

Powder Bed Fusion, a key additive manufacturing technique, builds complex metal parts layer-by-layer from powdered material, offering greater design flexibility and material efficiency compared to subtractive manufacturing, which removes material from a solid block through machining.

Directed Energy Deposition

Directed Energy Deposition (DED) in additive manufacturing enables precise metal layer-by-layer fabrication by melting materials with focused energy, contrasting with subtractive manufacturing that removes material from a solid block.

Electron Beam Melting

Electron Beam Melting (EBM) is an additive manufacturing technique that builds complex metal parts layer-by-layer using an electron beam, offering superior material efficiency and design flexibility compared to traditional subtractive manufacturing methods that remove material from solid blocks.

Selective Laser Sintering

Selective Laser Sintering, an additive manufacturing technique, builds complex, lightweight parts layer-by-layer from powdered materials, offering greater design flexibility and material efficiency compared to subtractive manufacturing, which removes material from a solid block.

Fused Deposition Modeling

Fused Deposition Modeling (FDM) in additive manufacturing builds objects layer-by-layer by extruding thermoplastic filaments, offering greater material efficiency and design complexity compared to traditional subtractive manufacturing, which removes material through cutting or machining processes.

CNC Machining

CNC machining, a subtractive manufacturing process, removes material from a solid block with precision, offering high accuracy and surface finish compared to additive manufacturing's layer-by-layer material buildup.

Hybrid Manufacturing

Hybrid manufacturing combines additive manufacturing's material efficiency and design freedom with subtractive manufacturing's precision and surface finish to optimize production speed, cost, and part quality.

Topology Optimization

Topology optimization enhances additive manufacturing by enabling the creation of complex, lightweight structures unachievable through subtractive manufacturing's material removal constraints.

Support Structure Removal

Support structure removal in additive manufacturing involves detaching excess material used for overhangs and complex geometries, whereas subtractive manufacturing typically requires minimal or no support removal due to the material being selectively cut away.

Near-Net Shape Fabrication

Near-net shape fabrication in additive manufacturing reduces material waste and machining time compared to the higher material removal and longer processing cycles typical of subtractive manufacturing.

Additive manufacturing vs Subtractive manufacturing Infographic

njnir.com

njnir.com