Reusable launch vehicles significantly reduce the cost per mission by enabling multiple flights with the same hardware, making space access more economical and sustainable. Single-use launch vehicles, while typically simpler in design and quicker to manufacture, generate higher expenses due to the need for entirely new components for each launch. Advances in materials engineering and propulsion systems are driving the development of reusable technologies, enhancing reliability and turnaround times compared to traditional expendable rockets.

Table of Comparison

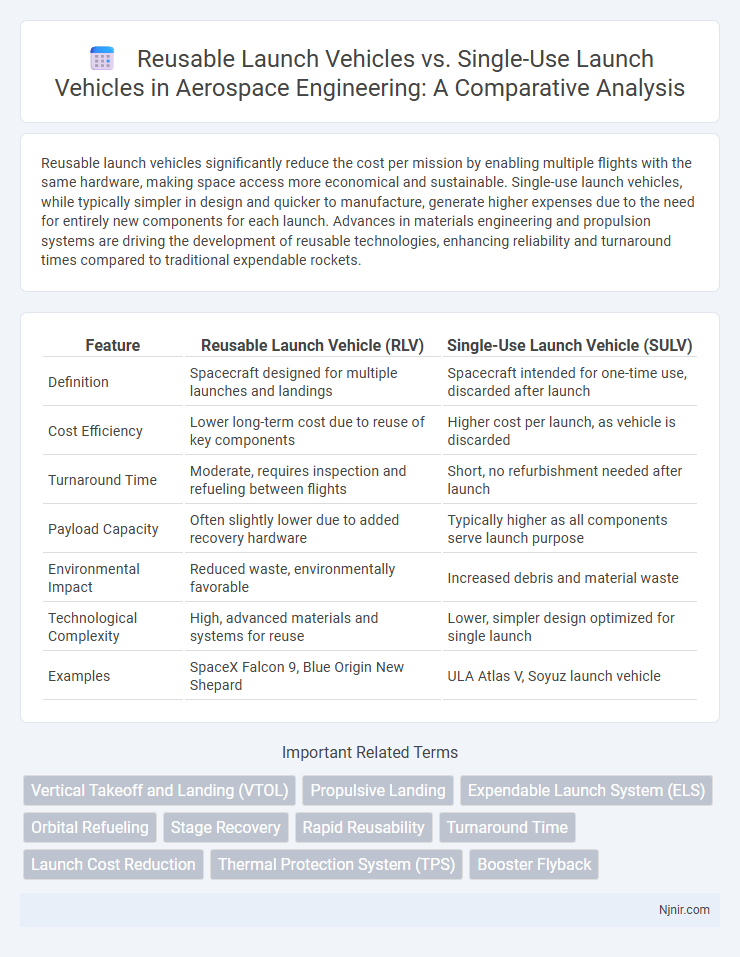

| Feature | Reusable Launch Vehicle (RLV) | Single-Use Launch Vehicle (SULV) |

|---|---|---|

| Definition | Spacecraft designed for multiple launches and landings | Spacecraft intended for one-time use, discarded after launch |

| Cost Efficiency | Lower long-term cost due to reuse of key components | Higher cost per launch, as vehicle is discarded |

| Turnaround Time | Moderate, requires inspection and refueling between flights | Short, no refurbishment needed after launch |

| Payload Capacity | Often slightly lower due to added recovery hardware | Typically higher as all components serve launch purpose |

| Environmental Impact | Reduced waste, environmentally favorable | Increased debris and material waste |

| Technological Complexity | High, advanced materials and systems for reuse | Lower, simpler design optimized for single launch |

| Examples | SpaceX Falcon 9, Blue Origin New Shepard | ULA Atlas V, Soyuz launch vehicle |

Introduction to Launch Vehicle Concepts

Reusable launch vehicles reduce overall mission costs by enabling multiple flights with the same hardware, incorporating advanced thermal protection and rapid refurbishment technologies. Single-use launch vehicles, designed for one-time missions, prioritize simplicity and cost-efficiency in manufacturing but result in higher expenses per launch due to hardware discard. Selection between these concepts hinges on mission frequency, payload requirements, and long-term operational sustainability.

Defining Reusable and Single-Use Launch Vehicles

Reusable launch vehicles are spacecraft designed to return to Earth intact after delivering payloads, allowing multiple flights and significantly reducing launch costs. Single-use launch vehicles, also known as expendable launch vehicles, are launched once and discarded, with their components either burning up on re-entry or remaining as space debris. The distinction lies in reusability, where reusable vehicles emphasize cost-efficiency and sustainability, while single-use vehicles prioritize simplicity and reliability for one-time missions.

Historical Evolution of Launch Systems

The historical evolution of launch systems highlights the transition from single-use launch vehicles, such as the Saturn V used during the Apollo missions, to the development of reusable launch vehicles like the Space Shuttle and SpaceX's Falcon 9. Early launch systems prioritized maximum payload capacity but resulted in high costs due to their expendable nature. Advances in materials, propulsion, and engineering have driven the shift toward reusable vehicles, significantly reducing launch costs and turnaround times while enabling more sustainable space exploration.

Key Technological Differences

Reusable launch vehicles incorporate advanced thermal protection systems, robust landing technologies such as vertical landing thrusters, and durable materials designed to withstand multiple reentries, enabling cost-effective multiple missions. Single-use launch vehicles prioritize lightweight structures and simplified propulsion systems optimized for one-time atmospheric descent, minimizing initial mass but incurring higher per-launch costs. Key technological differences also include the integration of onboard autonomic flight control systems in reusable vehicles to facilitate precise recovery, contrasting with disposable trajectories in expendable rockets.

Cost Analysis: Reusability vs. Expendability

Reusable launch vehicles significantly reduce overall mission costs by enabling multiple launches with the same hardware, while single-use launch vehicles incur higher expenses due to manufacturing new components for each flight. The initial investment in reusable technology is offset by decreased per-launch costs, exemplified by SpaceX's Falcon 9, which lowers price points compared to expendable rockets. Cost analysis reveals that reusability enhances economic sustainability in space access by minimizing production, refurbishment, and operational expenses.

Environmental Impact Comparison

Reusable launch vehicles significantly reduce environmental impact by minimizing the need for manufacturing new rockets, thus lowering resource consumption and waste generation compared to single-use launch vehicles. Single-use rockets contribute to higher carbon emissions and debris in the atmosphere due to their disposable nature and discarded components after each launch. Advances in reusable technology aim to decrease pollutant release and material waste, promoting sustainable practices in space exploration.

Reliability and Maintenance Considerations

Reusable launch vehicles offer enhanced reliability through iterative testing and refurbishment, allowing engineers to identify and address potential failures over multiple flights. Maintenance of reusable vehicles involves comprehensive inspections and part replacements, which can reduce long-term costs but require sophisticated logistics and turnaround time management. Single-use launch vehicles eliminate refurbishment complexity, simplifying maintenance but relying on manufacturing consistency to maintain reliability, often resulting in higher per-launch costs.

Mission Flexibility and Payload Capacity

Reusable launch vehicles enhance mission flexibility by enabling multiple launches with the same hardware, significantly reducing turnaround time and costs. Single-use launch vehicles often provide higher payload capacity per mission due to lighter structures optimized for one-time use, but lack the adaptability of repeated deployments. Balancing these factors is crucial in mission planning, with reusable systems favoring rapid, cost-effective launches and single-use vehicles maximizing payload delivery for specific missions.

Industry Case Studies: Falcon 9 vs. Ariane 5

Falcon 9's reusable first stage drastically reduces launch costs, enabling SpaceX to achieve over 100 successful landings and multiple reflights, exemplifying enhanced operational efficiency and cost-effectiveness in the commercial launch market. In contrast, Ariane 5 remains a single-use launcher with high reliability and payload capacity but incurs higher per-launch expenses due to its expendable design, limiting its competitive edge against reusable systems. Industry case studies reveal that Falcon 9's reusability drives significant cost savings and increased launch cadence, influencing market dynamics and accelerating the shift towards sustainable space access.

Future Trends in Launch Vehicle Development

Reusable launch vehicles are increasingly prioritized in future launch vehicle development due to their potential to significantly reduce costs and turnaround times, exemplified by SpaceX's Falcon 9 and Virgin Galactic's SpaceShipTwo. Advances in materials science, propulsion technology, and autonomous landing systems are driving improvements in reusability and reliability, encouraging agencies like NASA and private companies to invest in partially or fully reusable architectures. Single-use launch vehicles remain relevant for certain heavy-lift capabilities but face pressure to evolve toward reusability or modular designs to meet growing demand for sustainable and cost-effective access to space.

Vertical Takeoff and Landing (VTOL)

Reusable launch vehicles with Vertical Takeoff and Landing (VTOL) capabilities significantly reduce launch costs and turnaround time compared to single-use launch vehicles by enabling multiple flights from the same hardware.

Propulsive Landing

Propulsive landing in reusable launch vehicles enables controlled descent and multiple missions by using onboard engines to decelerate and land precisely, unlike single-use launch vehicles that rely on expendable descent methods and are discarded after one flight.

Expendable Launch System (ELS)

Expendable Launch Systems (ELS) offer cost-effective, mission-specific performance by using single-use rockets that eliminate the need for recovery and refurbishment associated with reusable launch vehicles.

Orbital Refueling

Orbital refueling enables reusable launch vehicles to extend mission durations and reduce costs compared to single-use launch vehicles dependent on one-time fuel loads.

Stage Recovery

Reusable launch vehicles recover and refurbish their stages for multiple flights, significantly lowering launch costs compared to single-use launch vehicles that discard stages after one mission.

Rapid Reusability

Rapid reusability in reusable launch vehicles significantly reduces launch costs and turnaround time compared to single-use launch vehicles designed for one-time missions.

Turnaround Time

Reusable launch vehicles achieve significantly shorter turnaround times by enabling rapid refurbishment and relaunch within days, whereas single-use launch vehicles require extensive manufacturing and preparation cycles that extend turnaround time to several months.

Launch Cost Reduction

Reusable launch vehicles significantly reduce launch costs by enabling multiple flights per vehicle, lowering the cost per kilogram of payload compared to single-use launch vehicles that require manufacturing a new rocket for each mission.

Thermal Protection System (TPS)

Reusable launch vehicles require advanced, durable Thermal Protection Systems (TPS) designed to withstand multiple re-entries and thermal cycles, whereas single-use launch vehicles utilize simpler, expendable TPS optimized for a single mission.

Booster Flyback

Reusable launch vehicles with booster flyback capabilities significantly reduce launch costs and environmental impact by enabling multiple flights, unlike single-use launch vehicles which discard boosters after one mission.

reusable launch vehicle vs single-use launch vehicle Infographic

njnir.com

njnir.com