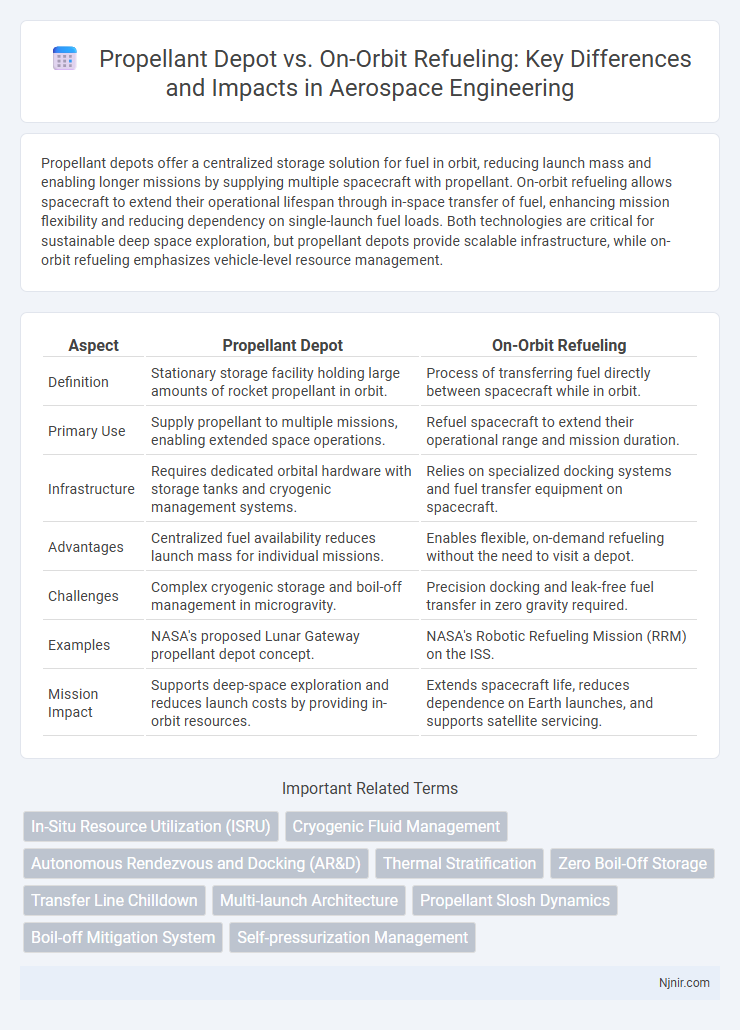

Propellant depots offer a centralized storage solution for fuel in orbit, reducing launch mass and enabling longer missions by supplying multiple spacecraft with propellant. On-orbit refueling allows spacecraft to extend their operational lifespan through in-space transfer of fuel, enhancing mission flexibility and reducing dependency on single-launch fuel loads. Both technologies are critical for sustainable deep space exploration, but propellant depots provide scalable infrastructure, while on-orbit refueling emphasizes vehicle-level resource management.

Table of Comparison

| Aspect | Propellant Depot | On-Orbit Refueling |

|---|---|---|

| Definition | Stationary storage facility holding large amounts of rocket propellant in orbit. | Process of transferring fuel directly between spacecraft while in orbit. |

| Primary Use | Supply propellant to multiple missions, enabling extended space operations. | Refuel spacecraft to extend their operational range and mission duration. |

| Infrastructure | Requires dedicated orbital hardware with storage tanks and cryogenic management systems. | Relies on specialized docking systems and fuel transfer equipment on spacecraft. |

| Advantages | Centralized fuel availability reduces launch mass for individual missions. | Enables flexible, on-demand refueling without the need to visit a depot. |

| Challenges | Complex cryogenic storage and boil-off management in microgravity. | Precision docking and leak-free fuel transfer in zero gravity required. |

| Examples | NASA's proposed Lunar Gateway propellant depot concept. | NASA's Robotic Refueling Mission (RRM) on the ISS. |

| Mission Impact | Supports deep-space exploration and reduces launch costs by providing in-orbit resources. | Extends spacecraft life, reduces dependence on Earth launches, and supports satellite servicing. |

Introduction to In-Space Propellant Logistics

Propellant depots serve as orbital storage facilities enabling spacecraft to replenish fuel without returning to Earth, significantly extending mission durations and reducing launch mass requirements. On-orbit refueling involves the transfer of propellant from these depots to active spacecraft, enhancing operational flexibility and enabling deep space exploration missions. Efficient in-space propellant logistics integrate both technologies to optimize fuel management, cut mission costs, and support sustainable space operations.

Propellant Depot: Concept and Architecture

Propellant depots serve as strategically positioned storage facilities in space, enabling spacecraft to refuel without returning to Earth. Their architecture typically includes cryogenic tanks, advanced insulation systems, and automated transfer mechanisms designed to minimize boil-off and ensure safe propellant handling. This infrastructure supports extended missions by providing a reliable supply of fuel, reducing launch mass, and enhancing overall mission flexibility in low Earth orbit (LEO) and beyond.

On-Orbit Refueling: Principles and Processes

On-orbit refueling involves the transfer of propellant between spacecraft while in space, enabling extended mission durations and increased operational flexibility. This process relies on precision docking, advanced fluid transfer technologies, and cryogenic propellant management to maintain fuel integrity in microgravity. Key principles include leak-proof connections, thermal control to prevent boil-off, and automated systems to ensure efficient and safe fuel transfer between vehicles.

Key Differences Between Propellant Depots and On-Orbit Refueling

Propellant depots are stationary storage facilities positioned in orbit that store large quantities of rocket fuel for spacecraft to dock and refuel, enhancing long-duration mission capabilities. On-orbit refueling refers to the process where spacecraft receive propellant directly from another vehicle or depot while in space, enabling extended missions without the need to carry all fuel from launch. The key differences lie in propellant depots serving as centralized fuel hubs, whereas on-orbit refueling is the dynamic transfer process occurring between spacecraft and these hubs or tanker vehicles.

Advantages of Propellant Depots in Aerospace Missions

Propellant depots offer significant advantages in aerospace missions by enabling reusable spacecraft to refuel in orbit, reducing the need to launch fully fueled vehicles and decreasing overall mission costs. They facilitate extended mission durations and increased payload capacity by providing flexible fuel supplies at strategic orbital locations. Propellant depots also enhance mission reliability by mitigating risks associated with launching heavy fuel loads from Earth.

Benefits and Challenges of On-Orbit Refueling

On-orbit refueling enhances spacecraft longevity and mission flexibility by enabling fuel resupply without returning to Earth, reducing launch costs and increasing operational ranges. The primary benefits include extending satellite lifespans, supporting deep-space missions, and facilitating modular spacecraft designs. Challenges involve docking precision, fuel transfer technology development, safety protocols for handling cryogenic propellants, and establishing standard interfaces across different spacecraft platforms.

Technical Requirements and Infrastructure

Propellant depots require extensive cryogenic storage systems with advanced insulation and zero-boil-off technologies to maintain fuel stability over long durations, demanding robust thermal management infrastructure in orbit. On-orbit refueling systems emphasize development of standardized docking interfaces, precise fluid transfer mechanisms, and contamination control to enable safe and efficient propellant transfer between spacecraft. Both approaches necessitate sophisticated robotics, reliable autonomous operations, and scalable support frameworks to ensure mission-critical fuel availability in space.

Impact on Mission Flexibility and Payload Capacity

Propellant depots significantly enhance mission flexibility by enabling spacecraft to refuel in orbit, allowing for longer missions and reduced launch mass compared to single-launch scenarios. On-orbit refueling increases payload capacity by reducing the amount of propellant a spacecraft must carry at launch, enabling more scientific instruments or cargo to be delivered. Both approaches optimize mission architecture, but propellant depots offer scalable infrastructure benefits, supporting multiple missions and extending operational lifetimes.

Current Projects and Future Developments

Current projects in propellant depots include NASA's NextSTEP program and Orbit Fab's Tanker-001, focusing on modular, autonomous refueling stations in low Earth orbit to enable sustainable deep space missions. On-orbit refueling advancements emphasize robotic fluid transfer technologies and cryogenic propellant storage improvements, with future developments targeting extended mission durations and reduced launch mass through in-space resource utilization. Emerging initiatives also explore fuel transfer compatibility across various spacecraft designs, advancing refueling infrastructure for lunar Gateway and Mars exploration missions.

Comparative Analysis: Propellant Depot vs On-Orbit Refueling

Propellant depots serve as stationary storage facilities in space, enabling multiple spacecraft to refuel without returning to Earth, whereas on-orbit refueling involves the direct transfer of fuel between spacecraft in active missions. Propellant depots offer scalability and longer-term support for extended missions, while on-orbit refueling provides flexibility for individual spacecraft by extending their operational range and mission duration. Both systems reduce launch mass and cost but differ in infrastructure complexity, with depots requiring robust storage and distribution technology, and on-orbit refueling demanding precise docking and fluid transfer mechanisms.

In-Situ Resource Utilization (ISRU)

Propellant depots relying on In-Situ Resource Utilization (ISRU) enable sustainable on-orbit refueling by harvesting and processing local extraterrestrial resources, reducing dependency on Earth-supplied fuel and enhancing deep space mission endurance.

Cryogenic Fluid Management

Cryogenic Fluid Management technologies enhance the efficiency and feasibility of propellant depots and on-orbit refueling by minimizing boil-off and ensuring long-term storage of cryogenic fuels in space.

Autonomous Rendezvous and Docking (AR&D)

Autonomous Rendezvous and Docking (AR&D) technology enhances both propellant depots and on-orbit refueling by enabling precise, efficient, and safe spacecraft alignment and connection without human intervention.

Thermal Stratification

Thermal stratification in propellant depots significantly enhances the efficiency of on-orbit refueling by maintaining temperature layers that reduce boil-off and preserve fuel integrity.

Zero Boil-Off Storage

Zero Boil-Off Storage technology significantly enhances propellant depots by maintaining cryogenic fuel integrity and enabling efficient on-orbit refueling without loss due to evaporation.

Transfer Line Chilldown

On-orbit refueling requires efficient transfer line chilldown to prevent propellant boil-off and enable stable cryogenic fluid transfer, whereas propellant depots incorporate advanced chilldown systems to maintain low temperatures for extended storage and seamless fuel distribution.

Multi-launch Architecture

Multi-launch architecture enhances propellant depot efficiency by enabling on-orbit refueling through multiple modular launches, reducing single-launch mass constraints and improving mission flexibility.

Propellant Slosh Dynamics

Propellant slosh dynamics critically impact the stability and control of both propellant depots and on-orbit refueling systems, with depots requiring advanced slosh mitigation techniques due to larger fluid volumes stored for prolonged periods in microgravity.

Boil-off Mitigation System

Boil-off Mitigation Systems in propellant depots significantly enhance on-orbit refueling efficiency by reducing cryogenic fuel loss and extending storage duration.

Self-pressurization Management

Self-pressurization management in propellant depots relies on passive thermal control to maintain tank pressure, whereas on-orbit refueling systems actively regulate pressurization through complex valves and compressors to ensure safe fuel transfer.

Propellant depot vs On-orbit refueling Infographic

njnir.com

njnir.com