Composite airframes offer superior strength-to-weight ratios compared to traditional aluminum airframes, leading to enhanced fuel efficiency and increased payload capacity in aerospace engineering. These advanced materials provide excellent corrosion resistance and fatigue durability, reducing maintenance costs and extending the lifespan of aircraft structures. Innovations in composite manufacturing enable complex aerodynamic designs that improve overall performance and operational flexibility over conventional aluminum frameworks.

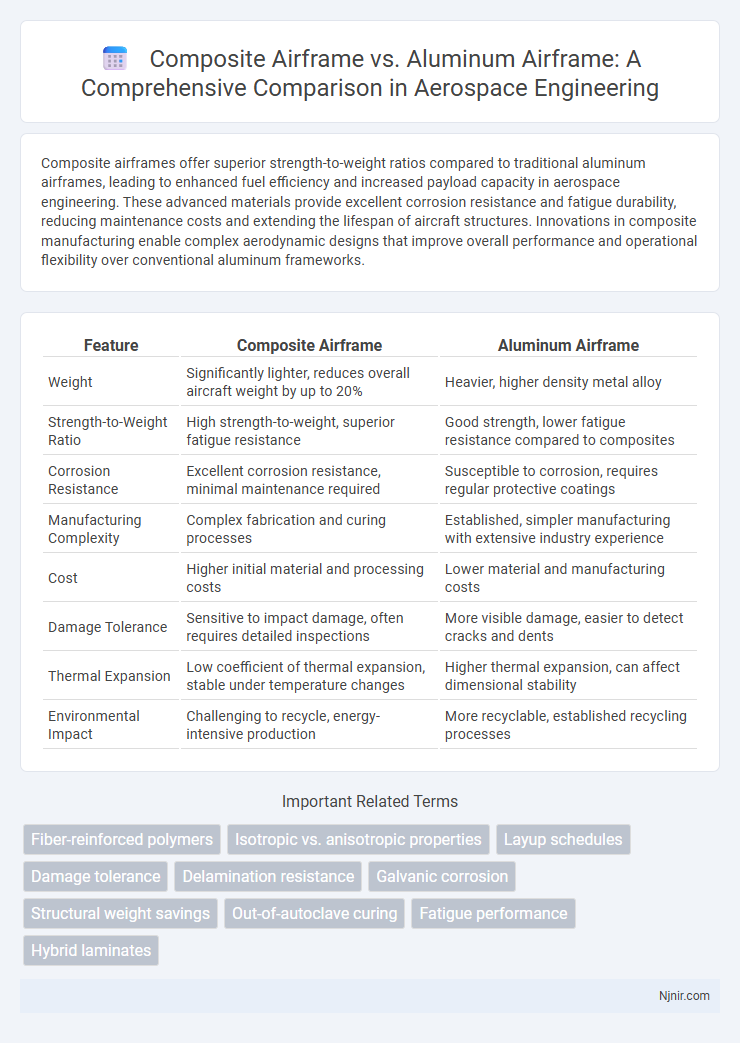

Table of Comparison

| Feature | Composite Airframe | Aluminum Airframe |

|---|---|---|

| Weight | Significantly lighter, reduces overall aircraft weight by up to 20% | Heavier, higher density metal alloy |

| Strength-to-Weight Ratio | High strength-to-weight, superior fatigue resistance | Good strength, lower fatigue resistance compared to composites |

| Corrosion Resistance | Excellent corrosion resistance, minimal maintenance required | Susceptible to corrosion, requires regular protective coatings |

| Manufacturing Complexity | Complex fabrication and curing processes | Established, simpler manufacturing with extensive industry experience |

| Cost | Higher initial material and processing costs | Lower material and manufacturing costs |

| Damage Tolerance | Sensitive to impact damage, often requires detailed inspections | More visible damage, easier to detect cracks and dents |

| Thermal Expansion | Low coefficient of thermal expansion, stable under temperature changes | Higher thermal expansion, can affect dimensional stability |

| Environmental Impact | Challenging to recycle, energy-intensive production | More recyclable, established recycling processes |

Introduction to Airframe Materials in Aerospace Engineering

Composite airframes in aerospace engineering offer enhanced strength-to-weight ratios, corrosion resistance, and fatigue durability compared to traditional aluminum airframes, improving fuel efficiency and performance. Aluminum airframes provide ease of manufacturing, cost-effectiveness, and proven structural reliability, making them suitable for many commercial and military aircraft applications. Advances in composite material technologies, such as carbon fiber reinforced polymers, are driving a shift towards composite airframes in modern aerospace design for optimized weight savings and structural integrity.

Overview of Composite and Aluminum Airframe Structures

Composite airframe structures, made from materials like carbon fiber reinforced polymers, offer superior strength-to-weight ratios and corrosion resistance compared to traditional aluminum airframes, which rely on lightweight metals known for durability and ease of repair. Aluminum airframes have been the industry standard for decades due to their proven performance, cost-effectiveness, and established manufacturing processes, while composites enable complex shapes and improved fuel efficiency through weight reduction. The choice between composite and aluminum airframes impacts aircraft performance, maintenance costs, and structural longevity, with composites increasingly favored in modern aerospace design for advanced capabilities.

Mechanical Properties: Strength-to-Weight Ratio Comparison

Composite airframes exhibit a superior strength-to-weight ratio compared to aluminum airframes, offering enhanced mechanical performance crucial for aerospace applications. The high tensile strength and stiffness of carbon fiber composites result in components that are lighter yet stronger, improving fuel efficiency and payload capacity. Aluminum alloys, while durable and cost-effective, are significantly heavier and less resistant to fatigue and corrosion, making composites the preferred choice for modern aircraft designs prioritizing weight reduction and structural integrity.

Manufacturing Processes: Composite vs. Aluminum Airframes

Composite airframes utilize advanced manufacturing processes such as automated fiber placement and resin transfer molding, enabling precise control over material distribution and reduced assembly time. Aluminum airframes rely on traditional techniques like riveting, machining, and sheet metal forming, which often involve more manual labor and higher material wastage. The composite process offers improved structural efficiency and corrosion resistance, while aluminum manufacturing benefits from established supply chains and easier reparability.

Durability and Fatigue Resistance in Airframe Materials

Composite airframes exhibit superior durability and fatigue resistance compared to traditional aluminum airframes, as carbon fiber-reinforced polymers resist corrosion and crack propagation more effectively under cyclic stress. Aluminum airframes, while lightweight and cost-effective, are prone to fatigue cracks and require frequent inspections and maintenance to prevent structural failure. Advancements in composite materials have enabled aircraft to achieve longer service lives and reduced maintenance costs by enhancing impact tolerance and extending damage tolerance thresholds.

Corrosion, Aging, and Environmental Impacts

Composite airframes exhibit superior corrosion resistance compared to aluminum airframes, significantly reducing maintenance costs and extending service life in marine and humid environments. Aluminum airframes are prone to galvanic corrosion and stress corrosion cracking, accelerating aging and compromising structural integrity over time. Environmental impacts favor composite materials due to their resistance to saltwater and moisture-induced degradation, whereas aluminum manufacturing and corrosion often result in higher environmental footprints.

Maintenance, Repairability, and Lifecycle Costs

Composite airframes offer superior corrosion resistance, reducing routine maintenance needs compared to aluminum airframes, which are prone to corrosion and require frequent inspections. Repairability of composites involves specialized techniques such as resin injections and patch repairs, often necessitating skilled labor, whereas aluminum structures allow more straightforward, cost-effective repairs using traditional metalworking methods. Lifecycle costs for composite airframes tend to be lower due to reduced corrosion-related expenses and longer fatigue life despite higher initial manufacturing costs, while aluminum airframes incur higher maintenance and repair expenses over time due to material degradation.

Performance Efficiency: Aerodynamics and Fuel Consumption

Composite airframes offer superior aerodynamic efficiency due to their smooth contours and reduced surface irregularities, which significantly decrease drag compared to traditional aluminum airframes. This enhanced aerodynamic profile contributes to lower fuel consumption, improving overall performance efficiency and extending flight range. The lightweight nature of composite materials also reduces aircraft weight, further optimizing fuel efficiency and operational costs.

Design Flexibility and Innovation Opportunities

Composite airframes offer superior design flexibility, enabling intricate shapes and integrated structures that reduce weight and improve aerodynamics compared to traditional aluminum airframes. The use of composites allows for innovative manufacturing techniques like additive layering and tailored fiber orientations, enhancing structural performance and durability. Aluminum airframes, while reliable and easier to repair, are limited by metal forming constraints, restricting advanced design possibilities and innovation potential.

Future Trends and Industry Adoption in Airframe Materials

Composite airframes are increasingly favored for future aircraft designs due to their lightweight properties, corrosion resistance, and superior fatigue performance compared to traditional aluminum airframes. Leading aerospace manufacturers such as Boeing and Airbus are expanding the use of carbon fiber reinforced polymers and other advanced composites to reduce fuel consumption and emissions, aligning with industry sustainability goals. Ongoing advancements in automated manufacturing technologies and recyclability of composite materials are accelerating industry adoption, signaling a significant shift towards composites in next-generation airframes.

Fiber-reinforced polymers

Fiber-reinforced polymer composite airframes offer superior strength-to-weight ratios and corrosion resistance compared to traditional aluminum airframes, enhancing fuel efficiency and aircraft durability.

Isotropic vs. anisotropic properties

Composite airframes exhibit anisotropic properties with direction-dependent strength and stiffness, while aluminum airframes possess isotropic characteristics, offering uniform mechanical properties in all directions.

Layup schedules

Composite airframe layup schedules involve precise layering of carbon fiber or fiberglass plies with resin to optimize strength-to-weight ratio, whereas aluminum airframe construction follows standardized sheet metal forming and riveting sequences prioritizing durability and ease of repair.

Damage tolerance

Composite airframes exhibit superior damage tolerance compared to aluminum airframes due to their ability to absorb impact energy and resist crack propagation.

Delamination resistance

Composite airframes exhibit superior delamination resistance compared to aluminum airframes, enhancing structural durability and reducing maintenance costs in aerospace applications.

Galvanic corrosion

Composite airframes resist galvanic corrosion better than aluminum airframes, which are prone to electrochemical reactions when in contact with dissimilar metals and moisture.

Structural weight savings

Composite airframes provide up to 20-30% structural weight savings compared to traditional aluminum airframes, enhancing fuel efficiency and payload capacity.

Out-of-autoclave curing

Out-of-autoclave curing enables composite airframes to be manufactured with lower costs and reduced weight compared to traditional aluminum airframes, while maintaining high structural strength and durability.

Fatigue performance

Composite airframes exhibit superior fatigue resistance and longer service life compared to aluminum airframes due to their enhanced crack propagation resistance and corrosion immunity.

Hybrid laminates

Hybrid laminates in composite airframes provide enhanced strength-to-weight ratios and corrosion resistance compared to traditional aluminum airframes, resulting in improved fuel efficiency and durability.

Composite airframe vs Aluminum airframe Infographic

njnir.com

njnir.com