Single-stage-to-orbit (SSTO) vehicles promise simpler design and potential reusability by eliminating staging events, but face significant challenges in achieving the necessary mass fraction and efficient propulsion for orbital insertion. Multi-stage-to-orbit (MSTO) rockets leverage sequential stages to shed weight and optimize performance, offering established reliability and higher payload capacity despite increased complexity and cost. Advances in materials, propulsion technologies, and structural optimization continue to shape the trade-offs between SSTO and MSTO architectures in aerospace engineering.

Table of Comparison

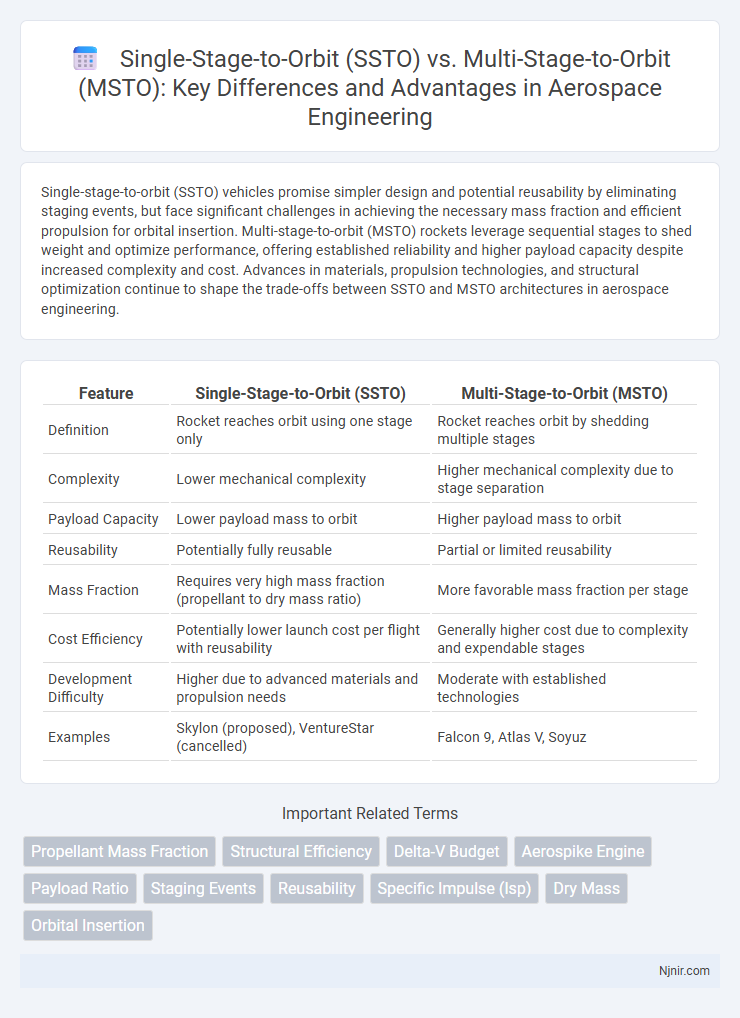

| Feature | Single-Stage-to-Orbit (SSTO) | Multi-Stage-to-Orbit (MSTO) |

|---|---|---|

| Definition | Rocket reaches orbit using one stage only | Rocket reaches orbit by shedding multiple stages |

| Complexity | Lower mechanical complexity | Higher mechanical complexity due to stage separation |

| Payload Capacity | Lower payload mass to orbit | Higher payload mass to orbit |

| Reusability | Potentially fully reusable | Partial or limited reusability |

| Mass Fraction | Requires very high mass fraction (propellant to dry mass ratio) | More favorable mass fraction per stage |

| Cost Efficiency | Potentially lower launch cost per flight with reusability | Generally higher cost due to complexity and expendable stages |

| Development Difficulty | Higher due to advanced materials and propulsion needs | Moderate with established technologies |

| Examples | Skylon (proposed), VentureStar (cancelled) | Falcon 9, Atlas V, Soyuz |

Introduction to Orbital Launch Systems

Single-stage-to-orbit (SSTO) vehicles aim to reach orbit using a single, reusable launch stage without discarding hardware, offering potential cost reductions and simplified turnaround. Multi-stage-to-orbit (MSTO) systems separate stages during ascent to optimize performance by shedding weight, enabling heavier payloads and higher velocities. SSTO designs face significant engineering challenges in propulsion efficiency and structural mass, whereas MSTO configurations benefit from proven scalability and staging flexibility.

Defining SSTO and MSTO Concepts

Single-Stage-to-Orbit (SSTO) refers to a launch vehicle designed to reach orbit using a single, continuous stage without jettisoning parts during ascent, emphasizing simplicity and reusability. Multi-Stage-to-Orbit (MSTO) involves multiple stages that detach sequentially, optimizing performance by shedding weight and enabling higher payload capacity. SSTO prioritizes structural efficiency and advanced propulsion, whereas MSTO leverages staging to overcome gravitational and atmospheric challenges.

Historical Developments in SSTO and MSTO

The historical development of single-stage-to-orbit (SSTO) vehicles traces back to early conceptual studies in the mid-20th century, with notable progress in the 1990s led by projects like the McDonnell Douglas DC-X, which demonstrated vertical landing and reusability concepts. Multi-stage-to-orbit (MSTO) systems, such as the Saturn V and Space Shuttle, have dominated spaceflight due to their proven reliability and efficiency, leveraging stage separation to optimize mass and propulsion. Advances in materials science and propulsion are ongoing, aiming to address SSTO challenges related to payload capacity and structural mass fraction, while MSTO designs continue to evolve through partial reusability and modular configurations.

Engineering Design Challenges

Single-stage-to-orbit (SSTO) vehicles face significant engineering design challenges such as achieving an extremely high mass fraction to carry sufficient propellant while minimizing structural weight and ensuring thermal protection during re-entry. Multi-stage-to-orbit (MSTO) systems mitigate these challenges by discarding spent stages to improve overall payload efficiency but introduce complexity in stage separation mechanisms, interstage aerodynamics, and system integration. Optimizing propulsion performance and managing the balance between structural integrity and fuel load remain critical challenges in both SSTO and MSTO designs.

Propulsion System Considerations

Single-stage-to-orbit (SSTO) vehicles require highly efficient propulsion systems with specific impulse values typically above 450 seconds to achieve orbit without shedding mass, demanding advanced materials and engine designs such as reusable rocket engines or air-breathing combined cycle engines. Multi-stage-to-orbit (MSTO) configurations allow for optimized propulsion stages, where each stage uses engines tailored to atmospheric and vacuum conditions, improving overall efficiency by discarding spent stages and reducing structural mass. Propulsion system considerations for SSTO emphasize minimizing dry mass and maximizing thrust-to-weight ratios, while MSTO designs benefit from flexibility in engine optimization and reduced structural complexity per stage.

Mass Fraction and Payload Efficiency

Single-stage-to-orbit (SSTO) vehicles typically have lower payload efficiency due to higher mass fractions, as they must carry all structural, propellant, and engine mass from liftoff without discarding stages. Multi-stage-to-orbit (MSTO) systems improve payload efficiency by shedding empty fuel tanks and engines during ascent, resulting in reduced mass fractions and increased payload capacity. Optimizing mass fraction is critical for SSTO viability, whereas MSTO designs leverage mass separation to maximize payload delivery to orbit.

Reusability and Maintenance Factors

Single-stage-to-orbit (SSTO) vehicles offer simplified reusability by eliminating stage separation mechanisms, reducing the number of parts requiring maintenance and inspections after each flight. Multi-stage-to-orbit (MSTO) designs, while often more efficient in payload capacity, involve multiple reusable components that increase maintenance complexity and turnaround time due to stage recovery, refurbishment, and integration processes. The trade-off in SSTO is typically higher design and material demands to withstand full orbital velocity and reentry without jettisoning hardware, impacting overall longevity and maintenance cycles.

Cost Analysis and Economic Viability

Single-stage-to-orbit (SSTO) vehicles offer reduced complexity and lower maintenance costs due to reusable components, but their high initial development expenses and limited payload capacity often result in higher per-launch costs. Multi-stage-to-orbit (MSTO) systems benefit from optimized fuel efficiency and larger payload capabilities, driving down marginal costs through proven staging technology and economies of scale. Economic viability favors MSTO for heavy-lift missions due to cost-effectiveness in mass production and operational flexibility, while SSTO suits niche markets with smaller payloads and rapid turnaround needs.

Notable Examples and Case Studies

Notable examples of single-stage-to-orbit (SSTO) vehicles include the X-33 and the Skylon spaceplane, designed to achieve orbit without jettisoning stages, showcasing innovations in reusable technology and fuel efficiency. Multi-stage-to-orbit (MSTO) systems, exemplified by the Saturn V and Falcon 9 rockets, have demonstrated proven reliability and payload versatility through sequential stage separation and optimized propulsion. Case studies highlight SSTO's potential for cost reduction and rapid turnaround, while MSTO remains dominant due to its current technical maturity and higher payload capacity.

Future Prospects and Emerging Technologies

Single-stage-to-orbit (SSTO) vehicles promise streamlined launch operations and reduced turnaround times, driven by advancements in lightweight composite materials and air-breathing propulsion systems. Multi-stage-to-orbit (MSTO) architectures benefit from mature technologies and flexible mission profiles, with emerging innovations in reusable rocket boosters and green propellants enhancing their cost-effectiveness and environmental footprint. Future prospects emphasize hybrid propulsion integration and autonomous flight systems, aiming to optimize payload capacity and reliability across both SSTO and MSTO platforms.

Propellant Mass Fraction

Single-stage-to-orbit (SSTO) vehicles require a higher propellant mass fraction, typically around 80-90%, compared to multi-stage-to-orbit (MSTO) rockets, which achieve orbit more efficiently by shedding mass and thus have lower overall propellant mass fractions per stage.

Structural Efficiency

Single-stage-to-orbit (SSTO) vehicles face challenges in structural efficiency due to heavier, integrated designs compared to multi-stage-to-orbit (MSTO) systems that optimize mass distribution across stages for improved overall structural performance.

Delta-V Budget

Single-stage-to-orbit (SSTO) vehicles require a significantly higher Delta-V budget, typically around 9.5 to 10 km/s, compared to multi-stage-to-orbit (MSTO) systems, which achieve orbit with combined stage Delta-Vs totaling approximately 8 to 9 km/s due to mass fraction optimization and stage shedding.

Aerospike Engine

The aerospike engine enhances single-stage-to-orbit (SSTO) efficiency by maintaining optimal thrust across varying altitudes, contrasting with multi-stage-to-orbit (MSTO) systems that rely on staged propulsion changes to maximize performance.

Payload Ratio

Single-stage-to-orbit (SSTO) vehicles typically have lower payload ratios compared to multi-stage-to-orbit (MSTO) rockets due to the increased mass fraction required to carry all propellant and structural components in a single stage.

Staging Events

Single-stage-to-orbit (SSTO) vehicles eliminate multiple staging events by reaching orbit with a single integrated system, whereas multi-stage-to-orbit (MSTO) rockets rely on sequential staging events to shed weight and optimize propulsion efficiency.

Reusability

Single-stage-to-orbit (SSTO) vehicles offer enhanced reusability by eliminating staging hardware, whereas multi-stage-to-orbit (MSTO) systems often face reusability challenges due to complex stage separation and recovery processes.

Specific Impulse (Isp)

Single-stage-to-orbit (SSTO) vehicles typically have lower Specific Impulse (Isp) efficiency compared to multi-stage-to-orbit (MSTO) rockets, as MSTO designs optimize fuel consumption and engine performance across stages to maximize overall Isp during ascent.

Dry Mass

Single-stage-to-orbit (SSTO) vehicles typically have higher dry mass fractions compared to multi-stage-to-orbit (MSTO) vehicles, resulting in reduced payload capacity and less efficient mass optimization.

Orbital Insertion

Single-stage-to-orbit (SSTO) vehicles achieve orbital insertion with a single propulsion system and no stage separation, while multi-stage-to-orbit (MSTO) vehicles increase efficiency by shedding weight through multiple stages, allowing higher payload capacity to orbit.

single-stage-to-orbit (SSTO) vs multi-stage-to-orbit (MSTO) Infographic

njnir.com

njnir.com