Aerospike nozzles maintain optimal thrust efficiency across a wide range of altitudes by adjusting the exhaust flow contour dynamically, unlike traditional bell nozzles, which are optimized for a specific altitude. The aerospike design reduces drag and improves fuel efficiency, making it ideal for reusable launch vehicles and multi-stage rockets. While bell nozzles are simpler and more tested, aerospikes offer superior performance in variable atmospheric conditions, enhancing payload capacity and mission flexibility.

Table of Comparison

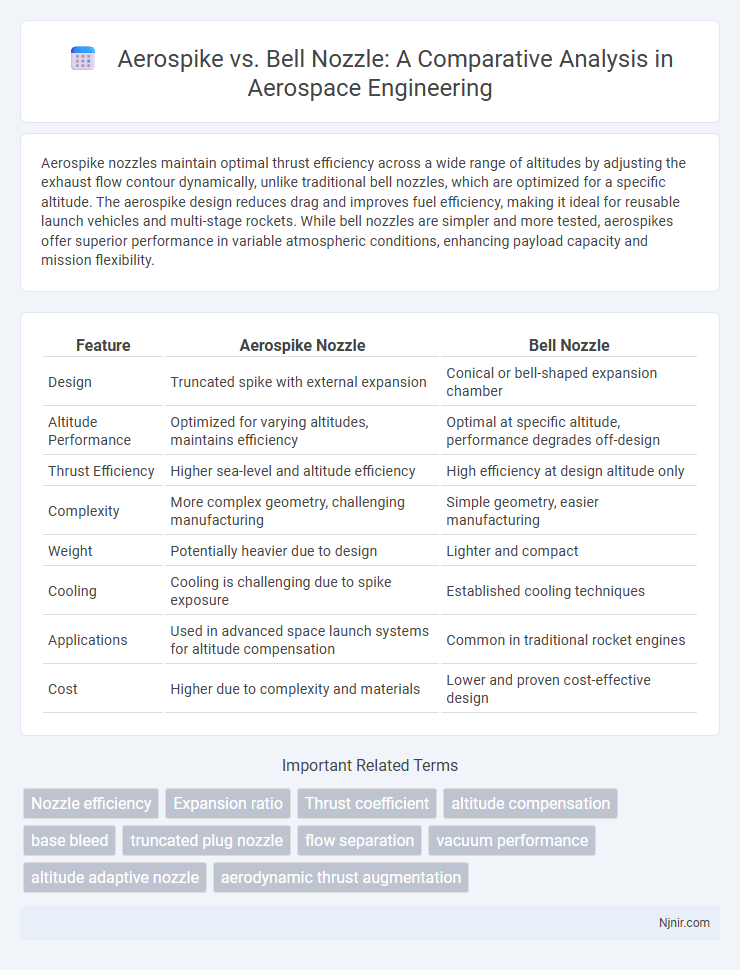

| Feature | Aerospike Nozzle | Bell Nozzle |

|---|---|---|

| Design | Truncated spike with external expansion | Conical or bell-shaped expansion chamber |

| Altitude Performance | Optimized for varying altitudes, maintains efficiency | Optimal at specific altitude, performance degrades off-design |

| Thrust Efficiency | Higher sea-level and altitude efficiency | High efficiency at design altitude only |

| Complexity | More complex geometry, challenging manufacturing | Simple geometry, easier manufacturing |

| Weight | Potentially heavier due to design | Lighter and compact |

| Cooling | Cooling is challenging due to spike exposure | Established cooling techniques |

| Applications | Used in advanced space launch systems for altitude compensation | Common in traditional rocket engines |

| Cost | Higher due to complexity and materials | Lower and proven cost-effective design |

Introduction to Rocket Nozzle Designs

Rocket nozzle designs primarily focus on converting high-pressure combustion gases into high-velocity exhaust for thrust generation. The Bell nozzle features a traditional contour that efficiently expands gases and maximizes exhaust velocity under specific atmospheric conditions. In contrast, the Aerospike nozzle uses an external plug to maintain optimal expansion across varying altitudes, improving efficiency by adapting to changing ambient pressures.

Fundamentals of Bell Nozzle Technology

The Bell Nozzle is engineered to optimize rocket engine exhaust flow by gradually expanding and directing gases to maximize thrust efficiency, employing a contour that balances pressure and velocity within the exhaust. Its fundamental design hinges on a bell-shaped contour that carefully manages flow separation and thermal stresses, ensuring effective propulsion at varying altitudes. This contrasts with the Aerospike nozzle's altitude-compensating capabilities, highlighting the Bell Nozzle's emphasis on stable, efficient performance through precise geometric shaping.

Aerospike Nozzle: Concept and Operation

The Aerospike nozzle is an advanced rocket engine design that maintains optimal efficiency across a wide range of altitudes by using a truncated spike that allows exhaust gases to expand against the surrounding atmosphere. Unlike traditional bell nozzles, which suffer performance losses due to fixed expansion ratios, the aerospike nozzle adapts its exhaust flow, reducing drag and improving thrust at both sea level and vacuum conditions. This adaptive expansion mechanism results in higher specific impulse and better fuel efficiency, making the aerospike nozzle a compelling choice for future space propulsion systems.

Efficiency Across Altitudes: Aerospike vs Bell

Aerospike nozzles maintain higher efficiency across a wide range of altitudes due to their altitude-compensating design, which adjusts exhaust expansion dynamically and reduces flow separation losses. Bell nozzles achieve optimal efficiency primarily at a specific design altitude, often causing performance drops at lower or higher altitudes due to overexpansion or underexpansion of exhaust gases. The adaptive expansion characteristic of aerospike engines results in more consistent thrust and fuel efficiency, critical for vehicles traversing diverse atmospheric pressures.

Thrust and Performance Comparison

Aerospike nozzles provide superior altitude compensation, maintaining higher thrust efficiency across varying atmospheric pressures compared to traditional bell nozzles that experience performance drops at different altitudes. The aerospike design enables near-optimal expansion of exhaust gases, resulting in improved specific impulse and overall propulsion efficiency. In contrast, bell nozzles are optimized for a fixed altitude, often delivering higher peak thrust at sea level but reduced effectiveness in vacuum conditions.

Structural and Manufacturing Considerations

Aerospike nozzles feature a truncated spike design that reduces base drag and improves thrust efficiency, but their complex geometry demands advanced manufacturing techniques such as 3D printing or precision machining to ensure structural integrity. Bell nozzles possess a more conventional, bell-shaped contour that simplifies fabrication using established casting and welding methods, resulting in robust structures capable of withstanding high thermal and mechanical stresses. Material selection for both nozzle types prioritizes high-temperature alloys and thermal barrier coatings to enhance durability and performance under extreme combustion chamber conditions.

Cooling Challenges and Thermal Management

Aerospike nozzles face significant cooling challenges due to their extended surface area exposed to high-temperature exhaust gases, requiring advanced regenerative or radiative cooling techniques to manage thermal loads effectively. Bell nozzles benefit from a more compact shape that simplifies thermal management but still demand robust cooling solutions, typically involving channel cooling or ablative materials to handle peak heat fluxes. Efficient thermal management in both nozzle types is critical for maintaining material integrity and optimizing performance, with aerospikes posing more complex design constraints due to their unique geometry and continuous expansion surface.

Applications in Modern Rocketry

Aerospike nozzles offer superior altitude compensation for efficient thrust across a wide range of atmospheric pressures, making them ideal for reusable launch vehicles and spaceplanes. Bell nozzles dominate in traditional expendable rocket stages due to their simpler design and proven performance in vacuum and low-atmosphere conditions. Modern rocketry increasingly explores aerospike technology to enhance payload capacity and fuel efficiency in multi-stage ascent profiles.

Limitations and Development Hurdles

The Aerospike nozzle, despite its superior altitude compensation and efficiency advantages over the traditional bell nozzle, faces significant development hurdles including complex cooling requirements and structural challenges due to its exposed ramp design. Manufacturing difficulties and higher costs arise from the intricate geometry and thermal stresses unique to Aerospike engines, limiting their widespread adoption in commercial applications. Bell nozzles remain dominant because of their simpler design, proven reliability, and ease of manufacturing, though they suffer efficiency losses at off-design altitudes compared to the adaptive performance of Aerospike nozzles.

Future Prospects in Aerospace Engineering

The Aerospike nozzle offers significant advantages over the traditional Bell Nozzle by maintaining optimal efficiency across a wide range of altitudes, making it highly suitable for future reusable launch vehicles and space exploration missions. Its altitude-compensating design reduces drag and improves thrust, which aligns with the aerospace industry's focus on enhancing fuel economy and mission versatility. Ongoing advancements in materials and additive manufacturing are expected to overcome current production challenges, positioning the Aerospike as a promising candidate for next-generation propulsion systems.

Nozzle efficiency

Aerospike nozzles maintain higher efficiency across a wide range of altitudes by minimizing flow separation and adapting exhaust expansion, whereas bell nozzles achieve peak efficiency only at specific design altitudes due to fixed contour geometry.

Expansion ratio

Aerospike nozzles maintain optimal expansion ratios across varying altitudes by dynamically adjusting exhaust flow, unlike traditional bell nozzles fixed at a specific expansion ratio optimized for either sea level or vacuum conditions.

Thrust coefficient

The Aerospike nozzle typically achieves a higher thrust coefficient than the Bell nozzle by maintaining optimal expansion across varying altitudes.

altitude compensation

The Aerospike nozzle offers superior altitude compensation by maintaining optimal exhaust expansion across varying atmospheric pressures, unlike the Bell nozzle which is optimized for a fixed altitude.

base bleed

Aerospike nozzles improve rocket engine efficiency by maintaining optimal expansion ratios at varying altitudes, while base bleed techniques in Bell nozzles reduce base drag by injecting gas into the wake region, enhancing overall aerodynamic performance.

truncated plug nozzle

The truncated plug nozzle, a variation of the Aerospike engine, reduces length and weight while maintaining efficient altitude compensation compared to the traditional bell nozzle.

flow separation

Aerospike nozzles maintain optimal thrust by preventing flow separation across varying altitudes, unlike traditional bell nozzles that experience flow separation losses at lower ambient pressures.

vacuum performance

The Aerospike nozzle delivers superior vacuum performance by maintaining higher thrust efficiency and reducing flow separation compared to the traditional Bell nozzle under varying ambient pressures.

altitude adaptive nozzle

The Aerospike nozzle maintains optimal thrust efficiency across varying altitudes by dynamically adjusting exhaust flow, unlike the traditional Bell nozzle which is optimized for a fixed altitude.

aerodynamic thrust augmentation

Aerospike nozzles enhance aerodynamic thrust by maintaining optimal expansion across varying altitudes, whereas bell nozzles experience performance losses due to fixed geometry limitations.

Aerospike vs Bell Nozzle Infographic

njnir.com

njnir.com