Gimbaled thrust systems achieve directional control by physically pivoting the entire engine or nozzle, enabling precise attitude adjustments without altering the exhaust flow pattern. Vectoring nozzles manipulate the exhaust jet's direction by deflecting the flow within a fixed nozzle structure, offering rapid response and enhanced maneuverability for high-performance aerospace vehicles. Both technologies optimize thrust vector control but differ in mechanical complexity, responsiveness, and integration suitability depending on mission requirements.

Table of Comparison

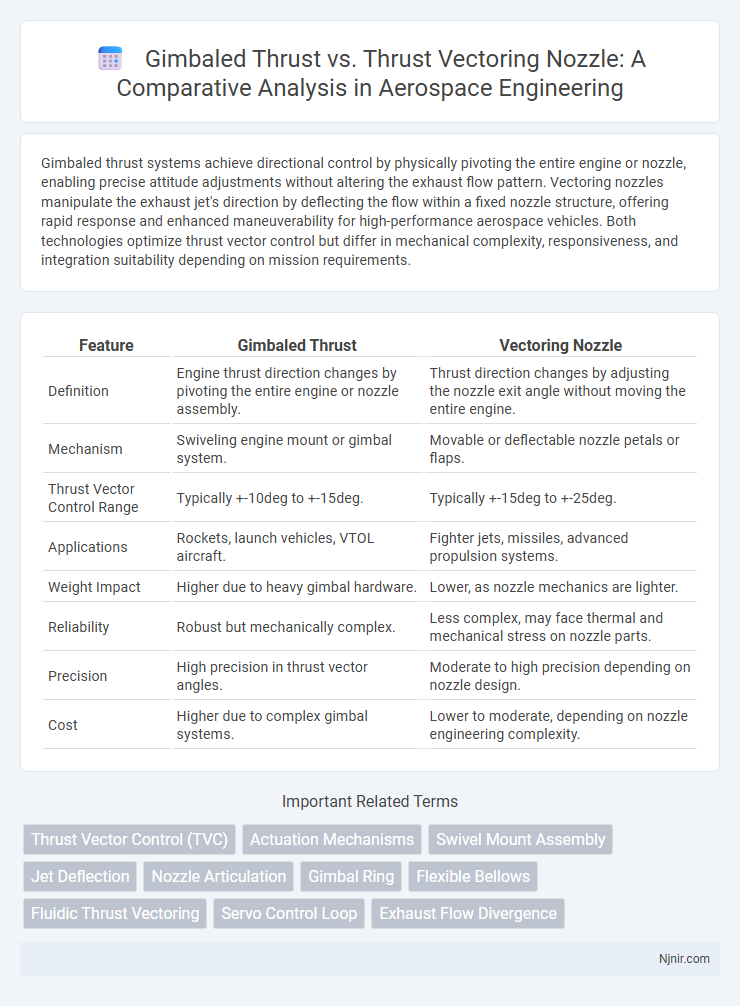

| Feature | Gimbaled Thrust | Vectoring Nozzle |

|---|---|---|

| Definition | Engine thrust direction changes by pivoting the entire engine or nozzle assembly. | Thrust direction changes by adjusting the nozzle exit angle without moving the entire engine. |

| Mechanism | Swiveling engine mount or gimbal system. | Movable or deflectable nozzle petals or flaps. |

| Thrust Vector Control Range | Typically +-10deg to +-15deg. | Typically +-15deg to +-25deg. |

| Applications | Rockets, launch vehicles, VTOL aircraft. | Fighter jets, missiles, advanced propulsion systems. |

| Weight Impact | Higher due to heavy gimbal hardware. | Lower, as nozzle mechanics are lighter. |

| Reliability | Robust but mechanically complex. | Less complex, may face thermal and mechanical stress on nozzle parts. |

| Precision | High precision in thrust vector angles. | Moderate to high precision depending on nozzle design. |

| Cost | Higher due to complex gimbal systems. | Lower to moderate, depending on nozzle engineering complexity. |

Introduction to Thrust Direction Control in Aerospace

Gimbaled thrust and vectoring nozzles are critical technologies for controlling thrust direction in aerospace applications, enabling precise maneuverability and stability of rockets and spacecraft. Gimbaled thrust systems mechanically pivot the entire engine or nozzle assembly, altering the thrust vector to steer the vehicle, while vectoring nozzles achieve directional control by deflecting the exhaust flow without moving the engine. Both methods optimize flight performance through advanced thrust vector control, enhancing trajectory adjustment and vehicle attitude during ascent, descent, and orbital maneuvers.

Fundamentals of Gimbaled Thrust Systems

Gimbaled thrust systems achieve directional control by pivoting the entire rocket engine around one or more axes, allowing the thrust vector to be angled relative to the vehicle's center of mass. This method provides precise attitude control by mechanically adjusting the engine's orientation, which is critical for stability and maneuverability during flight. Gimbaled thrust differs from vectoring nozzles that alter thrust direction through movable nozzle segments without repositioning the entire engine.

Principles of Thrust Vectoring Nozzle Technology

Thrust vectoring nozzle technology controls rocket or jet engine thrust direction by mechanically adjusting the nozzle's exit angle to steer the vehicle without altering the engine's orientation. Unlike gimbaled thrust systems that pivot the entire engine assembly, vectoring nozzles use movable flaps or flexible bellows within the nozzle to deflect exhaust flow, enabling more precise and rapid changes in thrust direction. This principle enhances maneuverability and stability in aerospace vehicles by dynamically modifying the exhaust plume shape and angle, optimizing flight control and performance.

Mechanisms: How Gimbaled Thrust Works

Gimbaled thrust operates by pivoting the entire engine or nozzle around one or more axes to direct the thrust vector, allowing precise control of a rocket's orientation and trajectory. This mechanism uses actuators and gimbals--ball-and-socket joints--that enable the engine to tilt in various directions, effectively steering the vehicle without changing the flow of exhaust gases. In contrast, vectoring nozzles deflect the exhaust flow by adjusting the shape or angle of the nozzle itself, rather than moving the entire engine assembly.

Mechanisms: How Vectoring Nozzles Operate

Vectoring nozzles operate by mechanically deflecting the engine exhaust flow through adjustable vanes or sleeves, allowing thrust direction changes without moving the entire engine. This mechanism enables precise control over pitch, yaw, and in some designs, roll by altering the angle of the nozzle exit. Compared to gimbaled thrust systems, vectoring nozzles offer faster response times and reduced structural stress by localizing the steering forces at the nozzle.

Performance Comparison: Maneuverability and Control

Gimbaled thrust systems offer superior maneuverability by allowing the entire engine to pivot, enabling precise directional control and rapid attitude adjustments in spacecraft and rockets. Vectoring nozzles achieve control by deflecting the exhaust flow without moving the entire engine, which provides faster response times but slightly less overall control authority compared to gimbaled systems. Performance comparison reveals that gimbaled thrust excels in stability and heavy-lift applications, while vectoring nozzles are favored in lightweight designs where quick maneuver responses are critical.

Structural Complexity and Weight Considerations

Gimbaled thrust systems feature engines mounted on pivoting structures allowing directional control, resulting in higher structural complexity due to the need for robust swivel joints and actuators. Vectoring nozzles simplify thrust direction by deflecting exhaust flow through movable flaps or vanes integrated into the nozzle, reducing mechanical components and overall weight. The reduced structural demands of vectoring nozzles make them advantageous for applications prioritizing weight savings and simplified engine design.

Impact on Vehicle Design and Integration

Gimbaled thrust systems enable precise directional control by physically pivoting the entire engine, offering enhanced stability and simpler integration with the vehicle's structure but often require more complex mechanical linkages and increased weight. Vectoring nozzles adjust the exhaust flow direction at the nozzle exit, allowing for more compact designs and potential weight savings while demanding advanced materials to withstand high thermal and mechanical stresses. Both methods significantly influence vehicle mass distribution, control system complexity, and overall structural design, with gimbaled thrusters favoring larger thrust applications and vectoring nozzles preferred in lightweight or reusable launch vehicles.

Reliability, Maintenance, and Lifecycle Cost

Gimbaled thrust systems offer superior reliability due to fewer moving parts in the nozzle compared to vectoring nozzles, which often require complex actuators and seals that increase maintenance demands. Maintenance for gimbaled thrust setups typically involves periodic checks of pivot bearings, resulting in lower downtime and reduced lifecycle costs. Vectoring nozzles, while providing enhanced directional control, generally incur higher long-term expenses due to frequent seal replacements and actuator servicing requirements.

Future Trends in Thrust Direction Technologies

Gimbaled thrust systems enable precise control of rocket direction through engine pivoting, while vectoring nozzles achieve thrust deflection by altering exhaust flow angles, each offering distinct advantages for maneuverability and efficiency. Future trends in thrust direction technologies are focusing on integration with advanced materials and real-time adaptive control algorithms to enhance responsiveness and reduce mechanical complexity. Innovations such as electromechanical actuators and additive manufacturing are expected to improve reliability and lower costs in next-generation aerospace propulsion systems.

Thrust Vector Control (TVC)

Gimbaled thrust provides precise thrust vector control by mechanically tilting the entire engine to steer a rocket, while vectoring nozzles achieve TVC by deflecting exhaust flow through movable nozzle parts, each offering distinct benefits in maneuverability and mechanical complexity.

Actuation Mechanisms

Gimbaled thrust systems use pivoting mounts controlled by hydraulic or electric actuators for directional control, while vectoring nozzles adjust exhaust flow angles through movable nozzle petals or vanes actuated by servomotors or hydraulic cylinders.

Swivel Mount Assembly

Swivel mount assemblies in gimbaled thrust systems enable precise nozzle articulation for directional control, while vectoring nozzles integrate movable vanes or secondary thrusters within the nozzle to alter exhaust flow without the need for a full mounting swivel mechanism.

Jet Deflection

Gimbaled thrust enables precise jet deflection by pivoting the entire engine, while vectoring nozzles achieve jet deflection through adjustable nozzle geometry, offering faster response but limited deflection angles.

Nozzle Articulation

Nozzle articulation in vectoring nozzles allows for precise directional control of exhaust flow by adjusting the nozzle exit angle, whereas gimbaled thrust achieves orientation changes by physically pivoting the entire engine assembly.

Gimbal Ring

The gimbal ring in gimbaled thrust systems enables precise directional control of rocket engines by pivoting the entire nozzle assembly, offering superior maneuverability compared to vectoring nozzles that adjust thrust through movable nozzle flaps or sections.

Flexible Bellows

Flexible bellows in gimbaled thrust systems provide enhanced nozzle articulation and durability compared to vectoring nozzles, enabling precise thrust direction control with reduced mechanical complexity.

Fluidic Thrust Vectoring

Fluidic thrust vectoring offers precise control of rocket engine exhaust flow by manipulating secondary fluid streams, enabling aerodynamic stability without mechanical gimbaled thrust components.

Servo Control Loop

Gimbaled thrust systems utilize precise servo control loops to adjust nozzle angles dynamically, providing enhanced vehicle stability and maneuverability compared to fixed vectoring nozzles.

Exhaust Flow Divergence

Gimbaled thrust controls rocket direction by pivoting the entire engine, minimizing exhaust flow divergence, whereas vectoring nozzles steer by deflecting the exhaust flow, increasing flow divergence and reducing propulsion efficiency.

Gimbaled Thrust vs Vectoring Nozzle Infographic

njnir.com

njnir.com