Ablative cooling in aerospace engineering involves the use of materials that slowly erode to absorb and dissipate heat during high-speed flight, providing thermal protection through sacrificial layers. Regenerative cooling circulates a coolant, often the propellant, through channels surrounding the engine or combustion chamber to absorb heat and preheat the propellant, enhancing efficiency and preventing thermal damage. Comparing both methods, ablative cooling is favored for short-duration, high-heat scenarios, while regenerative cooling supports continuous operation and improves overall engine performance.

Table of Comparison

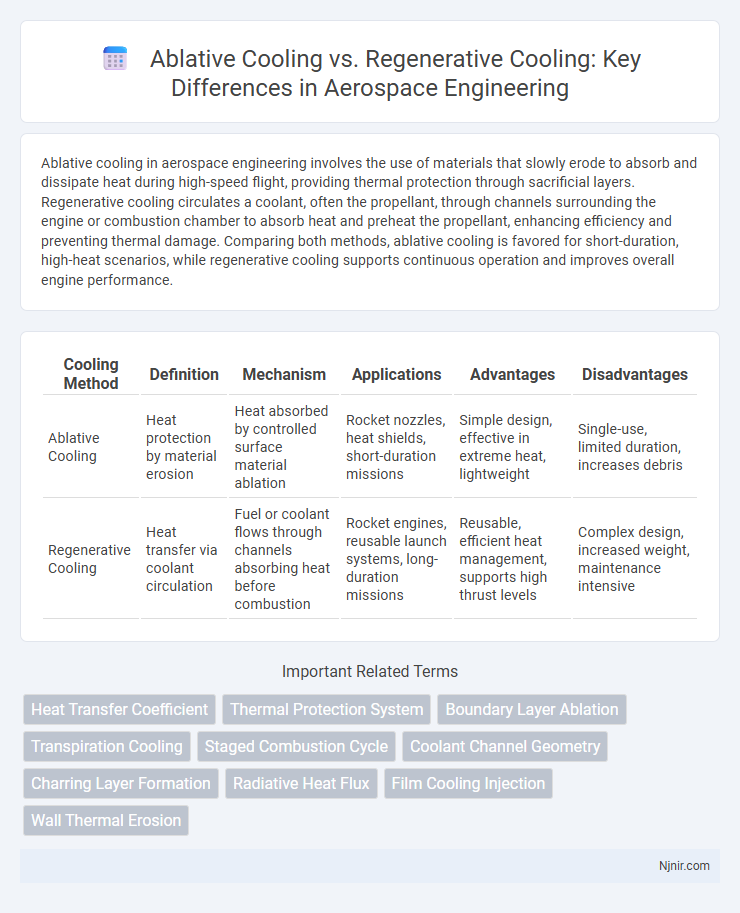

| Cooling Method | Definition | Mechanism | Applications | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Ablative Cooling | Heat protection by material erosion | Heat absorbed by controlled surface material ablation | Rocket nozzles, heat shields, short-duration missions | Simple design, effective in extreme heat, lightweight | Single-use, limited duration, increases debris |

| Regenerative Cooling | Heat transfer via coolant circulation | Fuel or coolant flows through channels absorbing heat before combustion | Rocket engines, reusable launch systems, long-duration missions | Reusable, efficient heat management, supports high thrust levels | Complex design, increased weight, maintenance intensive |

Introduction to Thermal Management in Rocket Engines

Ablative cooling and regenerative cooling are critical thermal management techniques used in rocket engines to prevent structural failure from extreme combustion temperatures. Ablative cooling relies on the gradual erosion of a sacrificial material layer to absorb and dissipate heat, while regenerative cooling circulates cryogenic propellants through channels around the combustion chamber to absorb heat and preheat the fuel. Effective thermal management through these methods enhances engine performance, reliability, and longevity during high-thrust operations.

Fundamentals of Ablative Cooling

Ablative cooling relies on the gradual erosion of a protective material layer that absorbs and carries away heat through phase change and material ablation, effectively insulating the underlying structure from extreme thermal environments. This fundamental process allows ablative materials such as carbon phenolic or silicone-based composites to protect rocket nozzles and combustion chambers by sacrificially removing heat and char layers. Unlike regenerative cooling, which circulates coolant fluids through channels to absorb heat actively, ablative cooling provides passive thermal protection by chemically and physically sacrificing the ablative surface.

Basics of Regenerative Cooling Systems

Regenerative cooling systems leverage the fuel or coolant to absorb heat from engine components, preventing overheating by circulating it through cooling channels before combustion. This method improves thermal efficiency and allows higher combustion temperatures compared to ablative cooling, which relies on material erosion to manage heat. By continuously recycling the coolant, regenerative systems maintain engine integrity and optimize performance in high-temperature environments.

Material Selection for Ablative vs Regenerative Cooling

Material selection for ablative cooling typically involves carbon-phenolic composites or reinforced polymers designed to char and erode gradually, providing thermal protection by absorbing and dissipating heat through the ablative process. In contrast, regenerative cooling requires high thermal conductivity materials such as copper alloys or high-performance stainless steels that facilitate efficient heat transfer by circulating coolant through cooling channels. The choice between ablative and regenerative materials hinges on balancing factors like operating temperature, thermal conductivity, structural integrity, and mission duration for optimal thermal management.

Thermal Performance Comparison

Ablative cooling utilizes a sacrificial material that absorbs heat through phase change and surface erosion, providing effective thermal protection in short-duration, high-intensity environments but with limited reusability. Regenerative cooling circulates propellant through cooling channels around the combustion chamber and nozzle, enabling efficient heat absorption and transfer while simultaneously preheating the propellant, leading to superior thermal performance and longer operational life. Thermal performance comparison shows regenerative cooling excels in sustaining prolonged high-temperature exposure with better heat dissipation, whereas ablative cooling is optimal for transient thermal loads due to its protective material consumption.

Advantages of Ablative Cooling

Ablative cooling offers superior thermal protection by gradually eroding material, which absorbs intense heat and prevents structural damage. This method requires less complex hardware compared to regenerative cooling, reducing overall system weight and increasing reliability. Its capability to handle extreme temperature spikes makes it ideal for high-heat aerospace applications like rocket nozzles and hypersonic vehicles.

Benefits of Regenerative Cooling

Regenerative cooling enhances thermal efficiency by circulating coolant through channels near engine walls, absorbing heat before reaching combustion chambers, which prevents overheating and structural damage. This method enables sustained high-performance operation by maintaining optimal engine temperatures and reducing the risk of material fatigue. Regenerative cooling also improves fuel efficiency and extends engine lifespan compared to ablative cooling, which relies on material erosion for heat dissipation.

Limitations and Challenges of Each Method

Ablative cooling faces limitations such as material consumption during operation, leading to finite mission durations and potential performance degradation due to surface erosion. Regenerative cooling challenges include complex manufacturing requirements and the risk of coolant leakage or channel clogging, which can impair heat transfer efficiency. Both methods must address thermal stresses and reliability concerns when used in high-temperature propulsion environments.

Applications in Aerospace Propulsion Systems

Ablative cooling, characterized by material erosion to absorb heat, is widely used in solid rocket motors and spacecraft reentry shields due to its simplicity and reliability under extreme thermal conditions. Regenerative cooling, which circulates propellant through cooling channels in the engine walls, is prevalent in liquid rocket engines like the Space Shuttle Main Engine and modern upper-stage engines, providing efficient thermal management and enabling higher performance. In aerospace propulsion systems, the choice between ablative and regenerative cooling depends on mission duration, engine complexity, and thermal load requirements.

Future Trends in Engine Cooling Technologies

Future trends in engine cooling technologies emphasize the integration of advanced ablative cooling materials with the efficiency of regenerative cooling systems to maximize thermal management in high-performance engines. Innovations include the development of hybrid cooling techniques that combine ablative coatings with regenerative cooling channels to enhance durability and reduce weight. Emerging research also explores nanomaterial-enhanced ablative composites and smart regenerative cooling architectures that adapt to real-time thermal loads for optimal engine performance.

Heat Transfer Coefficient

Regenerative cooling offers a higher heat transfer coefficient than ablative cooling by continuously circulating coolant through channels that absorb and remove heat efficiently from engine walls.

Thermal Protection System

Ablative cooling in Thermal Protection Systems relies on material erosion to absorb heat, while regenerative cooling circulates coolant through channels to actively remove heat and protect surfaces.

Boundary Layer Ablation

Boundary layer ablation in ablative cooling creates a protective sacrificial layer that reduces heat transfer, whereas regenerative cooling circulates coolant fluid to absorb heat before it reaches the engine walls.

Transpiration Cooling

Transpiration cooling, a subset of ablative cooling, uses porous materials to continuously bleed coolant through a surface, providing enhanced thermal protection compared to regenerative cooling systems that recirculate coolant within engine walls.

Staged Combustion Cycle

The staged combustion cycle utilizes regenerative cooling by circulating cryogenic propellant through engine walls to absorb heat efficiently, whereas ablative cooling relies on sacrificial material erosion to protect combustion chambers, making regenerative cooling more suited for high-performance staged combustion engines.

Coolant Channel Geometry

Ablative cooling features sacrificial material layers absorbing heat with simple coolant channels, while regenerative cooling employs complex, intricately designed coolant channel geometries to enhance heat transfer by circulating propellant through engine walls.

Charring Layer Formation

Ablative cooling relies on the controlled formation and erosion of a charring layer to absorb heat and protect the structure, whereas regenerative cooling minimizes charring by circulating coolant through channels to prevent thermal degradation.

Radiative Heat Flux

Ablative cooling reduces radiative heat flux by consuming a sacrificial material layer, while regenerative cooling minimizes radiative heat flux through continuous circulation of a coolant that absorbs and dissipates thermal energy.

Film Cooling Injection

Film cooling injection enhances ablative cooling by forming a protective coolant layer on surfaces, contrasting with regenerative cooling's internal heat exchange efficiency.

Wall Thermal Erosion

Ablative cooling reduces wall thermal erosion by sacrificially ablating heat-sensitive material, whereas regenerative cooling minimizes erosion by recycling coolant fluid through channels to absorb heat before expulsion.

Ablative Cooling vs Regenerative Cooling Infographic

njnir.com

njnir.com