Wind tunnel testing provides physical data on aerodynamic performance and flow behavior, capturing real-world phenomena such as turbulence and boundary layer effects that can be challenging to model accurately. Computational Fluid Dynamics (CFD) simulation offers detailed visualization and flexibility for analyzing complex geometries and flow conditions, but it relies heavily on assumptions and mesh quality that influence result accuracy. Combining both methods allows aerospace engineers to validate simulations with experimental results, optimizing aircraft design and performance efficiently.

Table of Comparison

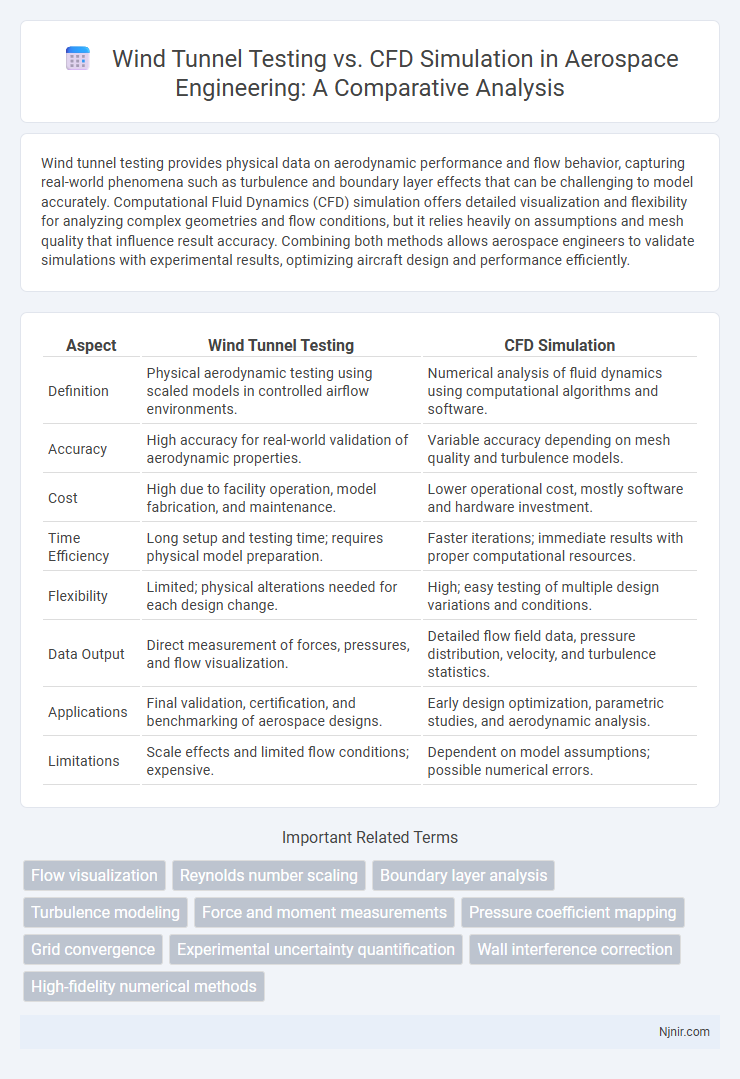

| Aspect | Wind Tunnel Testing | CFD Simulation |

|---|---|---|

| Definition | Physical aerodynamic testing using scaled models in controlled airflow environments. | Numerical analysis of fluid dynamics using computational algorithms and software. |

| Accuracy | High accuracy for real-world validation of aerodynamic properties. | Variable accuracy depending on mesh quality and turbulence models. |

| Cost | High due to facility operation, model fabrication, and maintenance. | Lower operational cost, mostly software and hardware investment. |

| Time Efficiency | Long setup and testing time; requires physical model preparation. | Faster iterations; immediate results with proper computational resources. |

| Flexibility | Limited; physical alterations needed for each design change. | High; easy testing of multiple design variations and conditions. |

| Data Output | Direct measurement of forces, pressures, and flow visualization. | Detailed flow field data, pressure distribution, velocity, and turbulence statistics. |

| Applications | Final validation, certification, and benchmarking of aerospace designs. | Early design optimization, parametric studies, and aerodynamic analysis. |

| Limitations | Scale effects and limited flow conditions; expensive. | Dependent on model assumptions; possible numerical errors. |

Introduction to Wind Tunnel Testing and CFD Simulation

Wind tunnel testing involves physically assessing aerodynamic properties by directing airflow over scaled models in controlled environments, providing precise measurements of forces and flow behavior. Computational Fluid Dynamics (CFD) simulation uses numerical algorithms to model fluid flow around objects, enabling virtual analysis of aerodynamic performance with adjustable parameters. Both methods are essential in aerospace and automotive industries for validating designs, with wind tunnels offering empirical data and CFD delivering detailed flow visualization and cost-effective iterations.

Historical Evolution in Aerospace Testing Methods

Wind tunnel testing, dating back to the early 20th century with pioneers like the Wright brothers and Gustave Eiffel, established foundational aerodynamic principles by physically replicating airflow over aircraft models, providing critical empirical data. Computational Fluid Dynamics (CFD) simulations emerged in the late 20th century, leveraging advancements in computer processing to solve complex fluid flow equations, thus enabling detailed visualization and analysis of aerodynamic properties without physical models. The historical evolution in aerospace testing methods reflects a shift from exclusively experimental approaches to hybrid models integrating wind tunnel data with high-fidelity CFD simulations, enhancing accuracy and reducing development costs in aircraft design.

Fundamental Principles of Wind Tunnel Testing

Wind tunnel testing relies on physical models placed in controlled airflows to measure aerodynamic forces, pressure distribution, and flow visualization using sensors and smoke trails. This method captures real-world fluid dynamics by directly simulating the interaction between air and the test object, providing accurate data for lift, drag, and turbulence. The fundamental principle involves replicating atmospheric conditions at scaled speeds to analyze airflow behavior and validate computational models like CFD simulations.

Core Concepts of CFD Simulation in Aerospace

CFD simulation in aerospace relies on solving the Navier-Stokes equations to model fluid flow around aircraft surfaces, enabling detailed analysis of aerodynamic properties such as lift, drag, and turbulence without physical prototypes. It provides high-resolution insight into complex flow phenomena through mesh generation and turbulence modeling techniques like Reynolds-Averaged Navier-Stokes (RANS) and Large Eddy Simulation (LES). While wind tunnel testing offers empirical validation through controlled experiments, CFD simulation accelerates design iterations by predicting performance under various flight conditions with computational efficiency.

Comparative Accuracy: Experimental Versus Numerical Approaches

Wind tunnel testing provides highly accurate, empirical data by replicating real-world aerodynamic conditions, capturing complex flow phenomena like turbulence and separation with physical sensors. CFD simulation relies on numerical algorithms solving fluid dynamics equations, offering detailed flow visualization but is subject to modeling assumptions and grid resolution limitations that can affect accuracy. Comparative accuracy depends on factors such as Reynolds number similarity, turbulence models in CFD, and scale effects in wind tunnel setups, often requiring validation of CFD results against experimental data for reliable predictions.

Time and Cost Efficiency in Wind Tunnel and CFD Methods

Wind tunnel testing involves significant setup time and high operational costs due to physical model construction and maintenance, making it less time-efficient. CFD simulation offers rapid iteration and lower expenses through virtual modeling, enabling extensive parameter testing without physical prototypes. However, CFD requires substantial computational resources and expertise, which can affect cost and time efficiency depending on project complexity.

Limitations and Challenges of Each Technique

Wind tunnel testing is limited by high costs, scale model inaccuracies, and physical constraints such as Reynolds number scaling and flow visualization challenges. CFD simulation faces challenges including the need for high computational power, sensitivity to turbulence models, and potential inaccuracies in complex flow predictions due to grid resolution and numerical methods. Both techniques require careful validation and often complement each other to overcome individual limitations in aerodynamic analysis.

Applications in Aircraft Design and Optimization

Wind tunnel testing provides empirical data on aerodynamic performance, pressure distribution, and flow behavior, essential for validating aircraft design concepts and improving lift-to-drag ratios. CFD simulation offers detailed visualization of airflow, enabling rapid iteration and optimization of wing shapes, control surfaces, and fuselage configurations while reducing the cost and time of physical prototypes. Combining wind tunnel results with high-fidelity CFD enhances accuracy in predicting aerodynamic forces, stability, and control characteristics critical for aircraft design refinement and certification.

Integration of Wind Tunnel Testing and CFD Simulation

Integrating wind tunnel testing with CFD simulation enhances aerodynamic analysis by combining empirical data with detailed flow visualization and numerical prediction. Wind tunnel tests provide physical validation for CFD models, improving accuracy in capturing complex flow phenomena and turbulence effects. The synergy accelerates design optimization, reduces development costs, and increases confidence in performance assessments across aerospace and automotive industries.

Future Trends in Aerodynamic Testing and Simulation

Future trends in aerodynamic testing and simulation emphasize the integration of high-fidelity CFD simulations with advanced wind tunnel testing, leveraging machine learning algorithms to enhance predictive accuracy and reduce physical testing costs. The adoption of digital twins and real-time data assimilation is accelerating, enabling adaptive optimization of aerodynamic designs throughout development cycles. Innovations in hybrid testing methodologies and increased computational power are driving more efficient, precise, and scalable solutions for aerospace and automotive industries.

Flow visualization

Wind tunnel testing provides direct, real-time flow visualization through smoke or dye injection, while CFD simulation offers detailed, adjustable 3D flow visualization with quantitative velocity and pressure data.

Reynolds number scaling

Wind tunnel testing offers precise Reynolds number scaling for accurate aerodynamic behavior replication, whereas CFD simulation often relies on turbulence models that may not fully capture Reynolds number effects at high flow conditions.

Boundary layer analysis

Wind tunnel testing provides empirical data for accurate boundary layer analysis under real flow conditions, while CFD simulation offers detailed velocity and pressure profiles enabling precise boundary layer prediction and optimization across varied scenarios.

Turbulence modeling

Wind tunnel testing provides empirical turbulence data for validating CFD simulations, which rely on advanced turbulence models like RANS, LES, and DES to predict complex airflow behaviors accurately.

Force and moment measurements

Wind tunnel testing provides direct, high-accuracy force and moment measurements crucial for validating computational fluid dynamics (CFD) simulations, which offer detailed flow visualization and parametric flexibility but depend on turbulence models and mesh quality for reliable aerodynamic force predictions.

Pressure coefficient mapping

Pressure coefficient mapping in wind tunnel testing provides empirical data with high spatial resolution, while CFD simulation enables detailed pressure distribution analysis over complex geometries under varied flow conditions.

Grid convergence

Grid convergence in CFD simulation is critical for validating accuracy, whereas wind tunnel testing provides empirical data but lacks computational grid refinement control.

Experimental uncertainty quantification

Wind tunnel testing presents inherent experimental uncertainty quantification challenges due to sensor errors, flow disturbances, and scale effects, whereas CFD simulation uncertainty primarily arises from numerical discretization, turbulence modeling, and boundary condition assumptions.

Wall interference correction

Wall interference correction in wind tunnel testing enhances aerodynamic data accuracy by compensating for blockage effects, while CFD simulation inherently avoids such interference, enabling precise flow analysis without physical constraints.

High-fidelity numerical methods

High-fidelity numerical methods in CFD simulation provide detailed aerodynamic data with precise flow behavior prediction, often surpassing traditional wind tunnel testing in cost-efficiency and flexibility for complex geometries.

wind tunnel testing vs CFD simulation Infographic

njnir.com

njnir.com