More-electric aircraft (MEA) emphasize electric power systems over traditional hydraulic and pneumatic systems, resulting in improved fuel efficiency and reduced emissions. The integration of high-voltage electrical networks enhances reliability, lowers maintenance costs, and increases overall aircraft performance. This shift supports the aerospace industry's goal of sustainable aviation and operational flexibility.

Table of Comparison

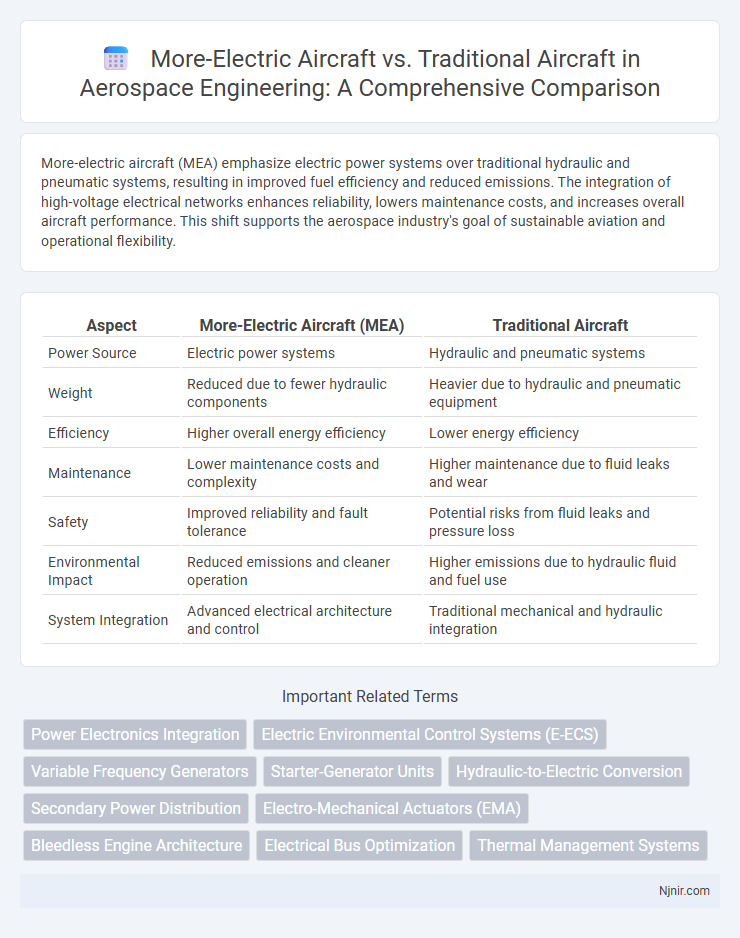

| Aspect | More-Electric Aircraft (MEA) | Traditional Aircraft |

|---|---|---|

| Power Source | Electric power systems | Hydraulic and pneumatic systems |

| Weight | Reduced due to fewer hydraulic components | Heavier due to hydraulic and pneumatic equipment |

| Efficiency | Higher overall energy efficiency | Lower energy efficiency |

| Maintenance | Lower maintenance costs and complexity | Higher maintenance due to fluid leaks and wear |

| Safety | Improved reliability and fault tolerance | Potential risks from fluid leaks and pressure loss |

| Environmental Impact | Reduced emissions and cleaner operation | Higher emissions due to hydraulic fluid and fuel use |

| System Integration | Advanced electrical architecture and control | Traditional mechanical and hydraulic integration |

Introduction to More-Electric Aircraft (MEA) and Traditional Aircraft

More-Electric Aircraft (MEA) integrate electrical systems to replace traditional hydraulic, pneumatic, and mechanical components, improving efficiency and reducing weight compared to Traditional Aircraft. MEA offers enhanced reliability, easier maintenance, and lower fuel consumption by utilizing advanced electrical power generation and distribution technologies. Conventional aircraft rely heavily on hydraulic and pneumatic systems for flight control and actuation, leading to increased maintenance demands and overall system complexity.

Key Differences in Aircraft Power Systems

More-electric aircraft (MEA) replace conventional hydraulic and pneumatic power systems with advanced electrical systems, significantly reducing mechanical complexity and maintenance costs. MEA utilize high-voltage electrical power distribution networks and electric actuators, enhancing efficiency and enabling better power management compared to traditional aircraft that rely on engine-driven hydraulic pumps and bleed air systems. The shift to electric power systems in MEA supports improved fuel efficiency, reduced emissions, and increased reliability through real-time monitoring and control.

Evolution of Electrical Systems in Aerospace Engineering

The evolution of electrical systems in aerospace engineering has led to a significant shift from traditional hydraulic and pneumatic systems to more-electric aircraft (MEA), enhancing energy efficiency and reducing weight. MEA replaces mechanical components with electric power, improving reliability, maintainability, and overall aircraft performance. Advanced power electronics, electric actuators, and increased onboard electrical power generation are key features driving this transformation in aerospace technology.

Advantages of More-Electric Aircraft

More-electric aircraft significantly reduce fuel consumption and emissions by replacing hydraulic and pneumatic systems with electrical alternatives, leading to improved energy efficiency and lower environmental impact. Enhanced system reliability and simplified maintenance result from fewer mechanical components and increased diagnostic capabilities, contributing to reduced operational costs and downtime. Integration of advanced electrical systems also enables improved aircraft performance, weight reduction, and greater flexibility in designing future aerospace technologies.

Limitations and Challenges of More-Electric Aircraft

More-electric aircraft face limitations such as increased electrical system complexity and higher weight due to additional wiring and power electronics. Thermal management challenges arise from the need to dissipate heat generated by high-power electrical components, impacting aircraft efficiency and reliability. Integration of advanced electric systems also demands robust certification processes and increased maintenance expertise to ensure safety and operational performance.

Impact on Aircraft Weight and Fuel Efficiency

More-electric aircraft replace hydraulic and mechanical systems with electric alternatives, significantly reducing overall aircraft weight by eliminating heavy pumps, fluid lines, and reservoirs. This weight reduction directly enhances fuel efficiency, leading to lower fuel consumption and decreased carbon emissions during flights. Studies indicate that more-electric designs can improve fuel economy by up to 10%, contributing to both operational cost savings and environmental sustainability.

Reliability and Maintenance Considerations

More-electric aircraft enhance reliability by reducing mechanical components prone to wear, such as hydraulic pumps and pneumatic systems. Electric systems improve diagnostic capabilities through advanced sensors, enabling predictive maintenance and decreasing unscheduled downtime. Maintenance costs decline due to simplified system architectures and fewer fluid leak risks compared to traditional hydraulic and pneumatic systems.

Environmental Benefits and Emissions Reduction

More-electric aircraft reduce carbon emissions by replacing hydraulic and pneumatic systems with electrically driven components, resulting in improved fuel efficiency and lower greenhouse gas output. The shift to electric systems decreases reliance on fossil fuels, cutting CO2, NOx, and particulate matter emissions significantly compared to traditional aircraft designs. Enhanced energy management and regenerative braking in more-electric aircraft contribute to overall reductions in environmental impact and support aviation sustainability goals.

Future Trends in Aircraft Electrification

Future trends in aircraft electrification emphasize the shift from traditional hydraulic and pneumatic systems to more-electric aircraft (MEA) architectures that improve energy efficiency and reduce emissions. MEA integration enhances system reliability and enables the use of advanced power electronics, electric motors, and energy storage technologies, driving innovations in hybrid-electric and fully electric propulsion. Industry leaders predict that by 2035, widespread adoption of MEA technologies will significantly lower operational costs and carbon footprints, accelerating the transition toward sustainable aviation.

Conclusion: The Path Forward for Aerospace Engineering

More-electric aircraft represent a transformative shift in aerospace engineering by enhancing energy efficiency, reducing emissions, and improving system reliability compared to traditional hydraulic and pneumatic systems. The integration of electrically powered components facilitates weight reduction and simplified maintenance, driving advancements in aircraft performance and sustainability. Continued innovation in power electronics, electric propulsion, and energy storage technologies will be critical to fully realize the potential of more-electric aircraft in future aviation designs.

Power Electronics Integration

Power electronics integration in more-electric aircraft enhances energy efficiency and reliability by replacing hydraulic and pneumatic systems with advanced electrical components, significantly reducing weight and maintenance costs compared to traditional aircraft.

Electric Environmental Control Systems (E-ECS)

More-electric aircraft utilize Electric Environmental Control Systems (E-ECS) that improve energy efficiency, reduce emissions, and enhance system reliability compared to traditional pneumatic-based ECS in conventional aircraft.

Variable Frequency Generators

Variable Frequency Generators in more-electric aircraft enhance power efficiency and weight reduction compared to fixed-frequency generators used in traditional aircraft.

Starter-Generator Units

More-electric aircraft employ advanced starter-generator units that enhance energy efficiency, reduce weight, and improve reliability compared to the mechanical starter systems in traditional aircraft.

Hydraulic-to-Electric Conversion

More-electric aircraft replace traditional hydraulic systems with advanced electric actuators, reducing weight, improving fuel efficiency, and enhancing system reliability.

Secondary Power Distribution

More-electric aircraft utilize advanced secondary power distribution systems featuring high-voltage DC architectures and smart power electronics, significantly improving efficiency, reliability, and weight reduction compared to traditional hydraulic and pneumatic-based secondary power systems.

Electro-Mechanical Actuators (EMA)

Electro-Mechanical Actuators (EMA) in more-electric aircraft enhance energy efficiency, reduce maintenance costs, and improve reliability compared to hydraulic systems used in traditional aircraft.

Bleedless Engine Architecture

Bleedless Engine Architecture in more-electric aircraft improves fuel efficiency and reduces maintenance by eliminating pneumatic bleed air systems traditionally used in conventional aircraft.

Electrical Bus Optimization

Electrical bus optimization in more-electric aircraft enhances power distribution efficiency and reliability compared to traditional aircraft by integrating advanced solid-state switches and adaptive load management systems.

Thermal Management Systems

More-electric aircraft use advanced thermal management systems with high-efficiency heat exchangers and smart sensors to optimize cooling of electric components, whereas traditional aircraft rely on conventional fluid-based cooling systems primarily designed for mechanical parts.

more-electric aircraft vs traditional aircraft Infographic

njnir.com

njnir.com