Flyback boosters are designed to return to the launch site for reuse, significantly reducing launch costs and environmental impact compared to expendable boosters that are discarded after a single use. The integration of advanced guidance systems and aerodynamic control surfaces enables flyback boosters to perform precise landing maneuvers, enhancing mission flexibility. Despite higher initial development costs, flyback technology offers long-term economic advantages through multiple reuse cycles and reduced manufacturing requirements.

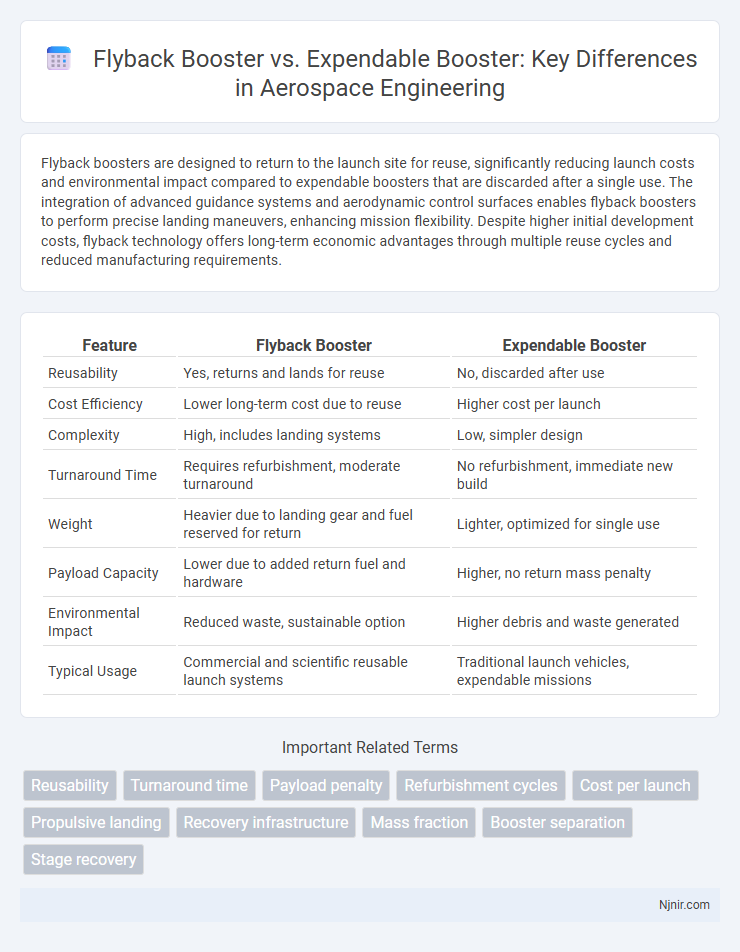

Table of Comparison

| Feature | Flyback Booster | Expendable Booster |

|---|---|---|

| Reusability | Yes, returns and lands for reuse | No, discarded after use |

| Cost Efficiency | Lower long-term cost due to reuse | Higher cost per launch |

| Complexity | High, includes landing systems | Low, simpler design |

| Turnaround Time | Requires refurbishment, moderate turnaround | No refurbishment, immediate new build |

| Weight | Heavier due to landing gear and fuel reserved for return | Lighter, optimized for single use |

| Payload Capacity | Lower due to added return fuel and hardware | Higher, no return mass penalty |

| Environmental Impact | Reduced waste, sustainable option | Higher debris and waste generated |

| Typical Usage | Commercial and scientific reusable launch systems | Traditional launch vehicles, expendable missions |

Introduction to Flyback and Expendable Boosters

Flyback boosters are designed to return to the launch site for refurbishment and reuse, significantly reducing launch costs and increasing sustainability in space missions. Expendable boosters are single-use rockets that are discarded after completing their mission, offering simpler design and reliability but higher operational expenses. Understanding the trade-offs between flyback and expendable boosters is critical for strategic decisions in aerospace engineering and commercial spaceflight.

Historical Evolution of Launch Boosters

The historical evolution of launch boosters reveals a shift from expendable boosters, such as the Saturn V's F-1 engines used during the Apollo era, to flyback boosters pioneered by companies like SpaceX with their Falcon 9 first stage. Expendable boosters were traditionally discarded after a single use, leading to high costs and resource inefficiency, whereas flyback technology emphasizes reusability and cost reduction by enabling controlled return and landing of the booster. Innovations in materials, avionics, and propulsion have accelerated this transition, marking a paradigm shift in space launch economics and sustainability.

Design Principles and Architecture Comparison

Flyback boosters feature integrated aerodynamic surfaces such as wings and grid fins, enabling controlled atmospheric reentry and powered horizontal landing, emphasizing reusability through propulsion and guidance systems. Expendable boosters prioritize structural simplicity and maximum thrust-to-weight ratio, designed for single-use operation with minimal recovery considerations, focusing on maximizing payload delivery efficiency. Architecturally, flyback boosters incorporate complex thermal protection systems and landing gear, whereas expendable boosters omit these to reduce mass and production cost, optimizing initial launch performance.

Propulsion Systems: Reusability vs. Single-use

Flyback boosters employ reusable propulsion systems designed for multiple launch cycles, utilizing controlled descent and powered landing techniques to preserve engine integrity and reduce refurbishment costs. Expendable boosters utilize single-use propulsion systems optimized for maximum thrust and payload capacity without considerations for recovery or reuse, leading to higher production expenses per launch. The trade-off between flyback and expendable boosters centers on balancing reusability benefits against propulsion efficiency and cost-effectiveness in launch vehicle design.

Aerodynamics and Flight Performance

Flyback boosters utilize aerodynamic surfaces like wings and control fins to achieve controlled, powered return flights, optimizing lift-to-drag ratios for efficient glide phases and precise landing. In contrast, expendable boosters prioritize maximum thrust-to-weight ratios and structural simplicity, sacrificing aerodynamic control for single-use ascent performance. The reusable flyback design demands advanced flight control algorithms to manage aerodynamic stability during reentry and landing, impacting overall flight trajectory and fuel consumption compared to the straightforward ballistic trajectories of expendable boosters.

Cost Analysis: Lifecycle and Operations

Flyback boosters reduce operational costs by enabling hardware reuse through controlled return and landing, significantly lowering production expenses across multiple launches. In contrast, expendable boosters incur higher lifecycle costs due to single-use components, requiring complete rebuilds or replacements after each mission. Cost analysis reveals flyback technology offers long-term savings despite higher initial development investments, optimizing overall launch economics.

Environmental Impact and Sustainability

Flyback boosters, designed for rapid reuse, significantly reduce waste and resource consumption compared to expendable boosters, which are discarded after a single flight. The environmental impact of flyback boosters is lower due to decreased need for manufacturing new components and reduced orbital debris generation. Sustainable spaceflight benefits from flyback technology by minimizing habitat disruption and conserving raw materials through repeated launches.

Mission Flexibility and Payload Considerations

Flyback boosters enable reusable launch operations by returning to the launch site, enhancing mission flexibility through rapid turnaround and multiple launch capabilities. Expendable boosters prioritize maximum payload delivery by utilizing full fuel capacity without the weight penalties of recovery systems, enabling heavier and more diverse payload accommodation. Mission planners balance between the recoverability benefit of flyback boosters and the increased payload capacity of expendable boosters based on launch frequency and mission-specific payload requirements.

Reliability, Risks, and Safety Factors

Flyback boosters offer enhanced reliability through controlled, powered landings that reduce structural stress compared to expendable boosters, which are discarded after a single use, increasing mission risk due to loss of hardware. The reusability of flyback boosters lowers operational costs but introduces safety challenges related to precise navigation and landing accuracy, while expendable boosters present fewer in-flight recovery risks but generate more space debris and environmental hazards. Safety factors for flyback boosters emphasize robust thermal protection and landing systems, whereas expendable boosters prioritize fail-safe separation and disposal mechanisms to mitigate explosion or debris hazards.

Future Trends in Aerospace Booster Technology

Flyback boosters are gaining traction for their reusability, significantly reducing launch costs and turnaround time compared to expendable boosters, which are discarded after a single use. Future trends emphasize enhancing propulsion efficiency, autonomous landing systems, and modular designs to improve flyback booster reliability and mission flexibility. Innovations in heat-resistant materials and advanced avionics are expected to further optimize performance and sustainability in aerospace booster technology.

Reusability

Flyback boosters offer enhanced reusability by returning to the launch site for refurbishment, whereas expendable boosters are discarded after a single use, increasing launch costs and material waste.

Turnaround time

Flyback boosters achieve significantly faster turnaround times by enabling rapid recovery and refurbishment, whereas expendable boosters require complete replacement, extending turnaround durations.

Payload penalty

Flyback boosters reduce payload penalty by enabling booster recovery and reuse, whereas expendable boosters maximize initial payload capacity but incur higher costs due to single-use design.

Refurbishment cycles

Flyback boosters are designed for rapid refurbishment and multiple reuse cycles, significantly reducing turnaround times and costs compared to expendable boosters, which are discarded after a single launch.

Cost per launch

Flyback boosters significantly reduce cost per launch by enabling full recovery and reuse, while expendable boosters incur higher expenses due to single-use components.

Propulsive landing

Propulsive landing enables flyback boosters to return safely for reuse, unlike expendable boosters which are discarded after a single launch.

Recovery infrastructure

Flyback boosters require complex runway and landing pad recovery infrastructure with advanced guidance systems, whereas expendable boosters eliminate recovery needs but increase overall launch costs and environmental impact.

Mass fraction

Flyback boosters achieve higher mass fractions by recovering and reusing the first stage, while expendable boosters sacrifice mass fraction due to complete stage discard after launch.

Booster separation

Flyback boosters perform controlled powered landings enabling precise, reusable booster separation, whereas expendable boosters separate through high-velocity detachment and are discarded after a single use.

Stage recovery

Flyback boosters enable controlled, powered return and landing for stage recovery, while expendable boosters are discarded and unrecovered after use.

flyback booster vs expendable booster Infographic

njnir.com

njnir.com