Turbofan engines offer higher fuel efficiency and lower noise levels compared to turbojets by using a large bypass fan that moves more air around the core engine. Turbojets excel at high speeds and altitudes due to their simpler design and higher exhaust velocity, making them suitable for supersonic flight. The choice between turbofan and turbojet depends on mission requirements, with turbofans favored for commercial aviation and turbojets for military and supersonic applications.

Table of Comparison

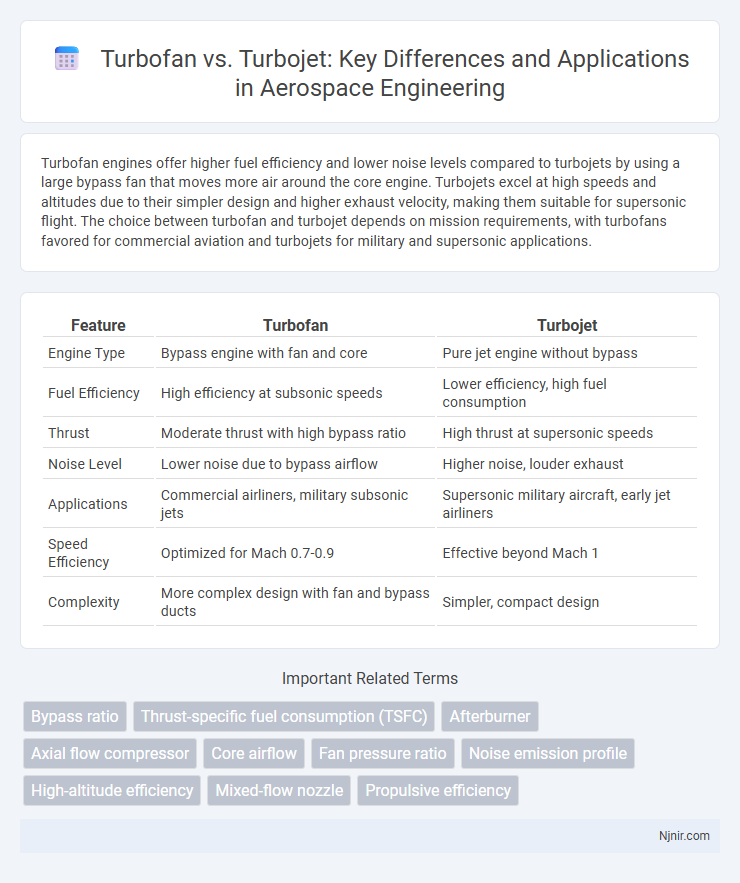

| Feature | Turbofan | Turbojet |

|---|---|---|

| Engine Type | Bypass engine with fan and core | Pure jet engine without bypass |

| Fuel Efficiency | High efficiency at subsonic speeds | Lower efficiency, high fuel consumption |

| Thrust | Moderate thrust with high bypass ratio | High thrust at supersonic speeds |

| Noise Level | Lower noise due to bypass airflow | Higher noise, louder exhaust |

| Applications | Commercial airliners, military subsonic jets | Supersonic military aircraft, early jet airliners |

| Speed Efficiency | Optimized for Mach 0.7-0.9 | Effective beyond Mach 1 |

| Complexity | More complex design with fan and bypass ducts | Simpler, compact design |

Introduction to Jet Engine Types

Turbofan and turbojet engines represent key categories of jet propulsion systems used in modern aviation. Turbofan engines combine a gas turbine core with a large fan that produces additional thrust by accelerating a mass of air around the core, resulting in higher fuel efficiency and quieter operation, making them ideal for commercial airliners. Turbojet engines generate thrust solely from high-velocity exhaust gases expelled through the engine's nozzle, providing superior speed and performance at high altitudes but with lower fuel efficiency and higher noise levels.

Turbofan Engine: Structure and Operation

Turbofan engines feature a large fan at the front, driven by a low-pressure turbine, which directs air through both the core engine and bypass duct, enhancing thrust and fuel efficiency compared to turbojets. The bypass air flow around the core engine reduces noise and increases propulsive efficiency, making turbofans ideal for commercial aircraft. Core components include the fan, compressor, combustor, turbine, and exhaust nozzle, working in unison to convert fuel energy into high-velocity airflow and propel the aircraft.

Turbojet Engine: Structure and Operation

The turbojet engine consists of an air intake, compressor, combustion chamber, turbine, and exhaust nozzle, working together to produce high-velocity jet thrust. Air enters the intake, is compressed by the axial compressor, mixed with fuel in the combustion chamber, and ignited to generate high-pressure gases that drive the turbine and exit at high speed through the nozzle. This straightforward design enables efficient operation at high speeds and altitudes but results in lower fuel efficiency and higher noise compared to turbofan engines.

Thrust Generation Mechanisms

Turbofan engines generate thrust primarily by accelerating a large volume of air through a fan, producing high bypass airflow that increases efficiency and reduces fuel consumption. Turbojet engines produce thrust by compressing and combusting air in a core engine, ejecting high-velocity exhaust gases directly to generate propulsion with a smaller bypass ratio. The key difference in thrust generation mechanisms lies in turbofans combining fan-driven bypass air and core exhaust, while turbojets rely solely on high-speed exhaust gas for thrust.

Fuel Efficiency Comparison

Turbofan engines exhibit significantly higher fuel efficiency than turbojets, especially at subsonic speeds, due to their larger bypass ratio that allows more air to bypass the core, reducing fuel consumption. Turbojets consume more fuel as they rely solely on high-speed exhaust gases for thrust, making them less efficient for commercial aviation and long-haul flights. The fuel-saving advantage of turbofans translates into lower operational costs and reduced environmental impact, making them the preferred choice for modern airliners.

Noise Levels and Environmental Impact

Turbofans produce significantly lower noise levels compared to turbojets due to their bypass airflow, which reduces jet exhaust velocity and noise pollution near airports. Turbojets emit higher levels of nitrogen oxides (NOx) and carbon dioxide (CO2) per unit of thrust, contributing to greater environmental impact and reduced fuel efficiency. Modern turbofan engines achieve improved fuel consumption and lower emissions, making them the preferred choice for commercial aviation and noise-sensitive environments.

Performance at Various Altitudes and Speeds

Turbofans deliver higher fuel efficiency and better thrust at subsonic speeds and lower altitudes due to their larger bypass ratios, making them ideal for commercial aviation. Turbojets excel at supersonic speeds and higher altitudes, providing greater specific thrust and performance where thinner air reduces engine drag. The selection between turbofan and turbojet hinges on mission profiles, with turbofans favoring economy in passenger jets and turbojets optimized for high-speed, high-altitude military applications.

Typical Applications in Aerospace

Turbofan engines are predominantly used in commercial airliners and military transport aircraft due to their superior fuel efficiency and lower noise levels at subsonic speeds. Turbojets are favored in supersonic military jets and reconnaissance aircraft where high-speed performance and a higher thrust-to-weight ratio are critical. The widespread adoption of turbofans in passenger aviation contrasts with the niche application of turbojets in specialized high-speed aerospace missions.

Maintenance and Lifecycle Considerations

Turbofan engines generally offer lower maintenance costs and longer lifecycle intervals compared to turbojet engines due to their advanced design and lower operating temperatures. The higher bypass ratio in turbofans reduces thermal stress on engine components, extending time between overhauls and enhancing durability. Turbojets, while simpler, often require more frequent inspections and parts replacements because of higher exhaust temperatures and faster wear rates during operation.

Future Trends in Jet Propulsion

Turbofan engines are expected to dominate future commercial aviation due to their superior fuel efficiency and reduced noise emissions compared to turbojets, which remain relevant primarily in military and supersonic applications. Advances in high-bypass turbofan technology and the integration of sustainable aviation fuels are driving significant reductions in carbon footprints. Emerging trends include adaptive cycle engines that blend turbofan and turbojet features to optimize performance across various flight regimes.

Bypass ratio

Turbofan engines feature a high bypass ratio that improves fuel efficiency and reduces noise compared to turbojets, which have a low or zero bypass ratio.

Thrust-specific fuel consumption (TSFC)

Turbofans achieve lower thrust-specific fuel consumption (TSFC) than turbojets by using a bypass airflow that improves fuel efficiency at subsonic speeds.

Afterburner

Turbofan engines use afterburners to boost thrust efficiently at supersonic speeds, while turbojets rely on afterburners for significant thrust increase but with higher fuel consumption.

Axial flow compressor

Turbofan engines use axial flow compressors to achieve higher pressure ratios and fuel efficiency compared to turbojets, which rely on axial flow compressors primarily for maximizing thrust in high-speed flight.

Core airflow

Turbofan engines optimize core airflow by mixing bypass air with core exhaust to improve efficiency and reduce fuel consumption, while turbojet engines direct all airflow through the core, maximizing thrust but increasing fuel use.

Fan pressure ratio

Turbofans typically have a lower fan pressure ratio ranging from 1.5 to 3.5, enhancing fuel efficiency and reducing noise compared to turbojets, which feature higher overall pressure ratios but lack a large fan stage.

Noise emission profile

Turbofans produce lower noise emissions than turbojets due to their higher bypass ratio, which results in reduced jet velocity and quieter operation.

High-altitude efficiency

Turbofans achieve higher high-altitude efficiency than turbojets by utilizing larger bypass ratios that increase thrust while reducing fuel consumption and noise.

Mixed-flow nozzle

The mixed-flow nozzle in turbofans enhances thrust efficiency and fuel economy by combining bypass and core exhaust streams, unlike turbojets that utilize a single-flow nozzle for higher speed but lower overall efficiency.

Propulsive efficiency

Turbofans exhibit higher propulsive efficiency than turbojets due to their larger bypass ratio, which produces more thrust with less fuel consumption at subsonic speeds.

Turbofan vs Turbojet Infographic

njnir.com

njnir.com