Morphing wings adapt their shape in real-time to enhance aerodynamic efficiency and maneuverability, offering significant improvements over fixed wings in fuel efficiency and flight performance. Fixed wings provide structural simplicity and reliability, making them suitable for steady, long-duration flights but lack the adaptability to changing flight conditions. Advances in materials and actuation technologies enable morphing wings to reduce drag and improve lift-to-drag ratios, revolutionizing the design of future aerospace vehicles.

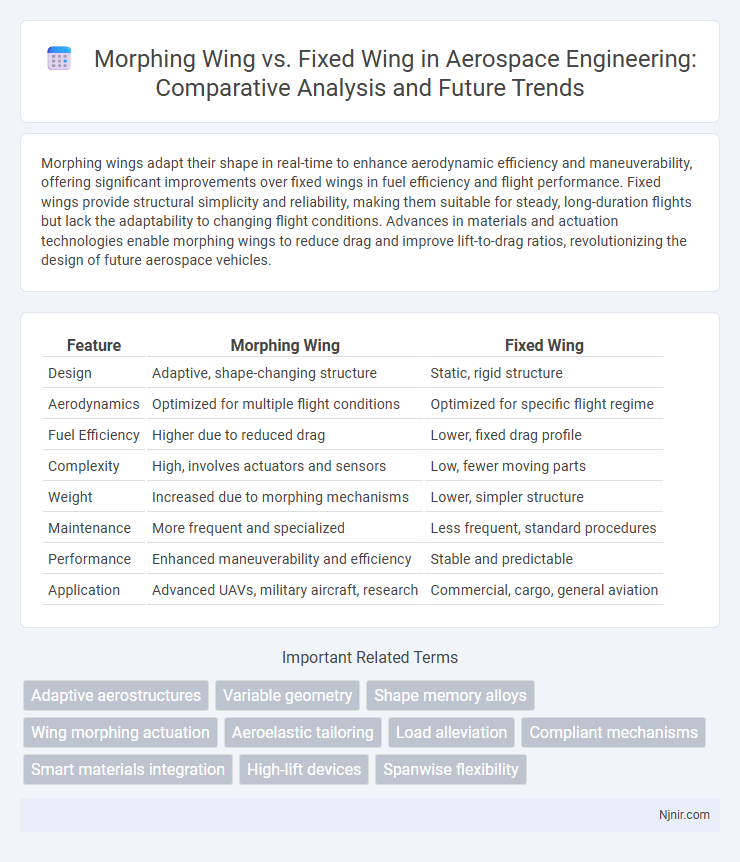

Table of Comparison

| Feature | Morphing Wing | Fixed Wing |

|---|---|---|

| Design | Adaptive, shape-changing structure | Static, rigid structure |

| Aerodynamics | Optimized for multiple flight conditions | Optimized for specific flight regime |

| Fuel Efficiency | Higher due to reduced drag | Lower, fixed drag profile |

| Complexity | High, involves actuators and sensors | Low, fewer moving parts |

| Weight | Increased due to morphing mechanisms | Lower, simpler structure |

| Maintenance | More frequent and specialized | Less frequent, standard procedures |

| Performance | Enhanced maneuverability and efficiency | Stable and predictable |

| Application | Advanced UAVs, military aircraft, research | Commercial, cargo, general aviation |

Introduction to Morphing Wings and Fixed Wings

Morphing wings offer adaptive aerodynamic surfaces that can change shape in response to flight conditions, enhancing fuel efficiency and maneuverability compared to traditional fixed wings. Fixed wings maintain a rigid, static airfoil design optimized for specific flight regimes, providing structural simplicity and reliability. The integration of smart materials and actuation systems enables morphing wings to dynamically optimize lift-to-drag ratios across diverse flight phases, surpassing the performance constraints of fixed wing configurations.

Historical Evolution of Wing Technologies

The historical evolution of wing technologies highlights the transition from traditional fixed wings to advanced morphing wings, driven by the need for enhanced aerodynamic efficiency and adaptability. Fixed wings dominated early aviation with their simple, robust designs and predictable performance, while morphing wings emerged through research on flexible materials and control mechanisms that allow dynamic shape changes during flight. Innovations in smart materials, aerospace engineering, and computational modeling have propelled morphing wing development, promising significant improvements in fuel efficiency, maneuverability, and mission versatility over fixed-wing counterparts.

Fundamental Design Differences

Morphing wings feature adaptable structures that alter shape in response to flight conditions, enhancing aerodynamic efficiency and maneuverability, unlike fixed wings which maintain a constant, rigid geometry optimized for specific flight regimes. The fundamental design of morphing wings integrates flexible materials, actuators, and control systems to enable continuous shape modulation, whereas fixed wings rely on fixed airfoil profiles and conventional control surfaces such as ailerons and flaps. This intrinsic difference affects overall aircraft performance, with morphing wings promising improved lift-to-drag ratios and fuel efficiency by dynamically optimizing wing configuration in real-time.

Aerodynamic Performance Comparison

Morphing wings offer superior aerodynamic performance compared to fixed wings by dynamically adjusting their shape to optimize lift-to-drag ratios across various flight conditions, enhancing fuel efficiency and maneuverability. Fixed wings, while structurally simpler and more robust, are optimized for a specific flight regime, leading to less efficient performance outside that range. Advanced morphing wing technologies enable continuous shape adaptation, reducing drag during cruise and increasing lift during takeoff and landing, resulting in improved overall flight efficiency.

Structural Complexity and Material Innovations

Morphing wings exhibit higher structural complexity than fixed wings due to their ability to change shape in response to aerodynamic conditions, requiring advanced actuation systems and flexible materials. Innovations in smart materials, such as shape memory alloys and piezoelectric composites, enable dynamic wing morphing by providing lightweight, adaptable structures that maintain aerodynamic efficiency. Fixed wings rely on traditional rigid materials like aluminum and composites, offering simpler structural designs but limited adaptability compared to morphing wing systems.

Weight Implications and Load Distribution

Morphing wings offer dynamic load distribution by altering shape to optimize lift and reduce structural stress, resulting in potentially lighter designs compared to fixed wings that rely on heavier, rigid structures to handle static loads. The adjustable configuration of morphing wings allows for improved weight efficiency by minimizing the need for excess material reinforcement found in fixed-wing aircraft. However, the added complexity of actuators and control mechanisms in morphing wings can offset some weight savings, demanding a careful balance between structural weight and system components.

Flight Efficiency Across Different Missions

Morphing wings adapt their shape in real-time to optimize aerodynamic performance, significantly enhancing flight efficiency across varied mission profiles by reducing drag and improving lift-to-drag ratios. Fixed wings, while structurally simpler and lighter, are designed for optimal efficiency at a specific flight condition, leading to suboptimal performance during diverse mission phases such as takeoff, cruising, and maneuvering. Advanced morphing wing technology enables versatile aerodynamic tuning, resulting in fuel savings, extended range, and improved payload capacity compared to traditional fixed-wing configurations.

Maintenance, Reliability, and Lifecycle Costs

Morphing wings reduce maintenance complexity by adapting shape to flight conditions, lowering wear compared to fixed wings with rigid structures. Reliability improves as morphing systems utilize advanced sensors and actuators, enabling real-time adjustments that mitigate structural stress and fatigue. Lifecycle costs often decrease due to extended airframe longevity and fuel savings despite higher initial investment in morphing technology.

Applications in Modern Aerospace Systems

Morphing wings enhance aerodynamic efficiency and maneuverability in modern aerospace systems by dynamically adjusting shape for varying flight conditions, outperforming fixed wings that maintain a constant geometry. These adaptive structures improve fuel efficiency, extend range, and enable better control in unmanned aerial vehicles, military aircraft, and next-generation commercial planes. Fixed wings continue to dominate traditional aircraft designs due to structural simplicity and reliability but lack the versatility and performance benefits offered by morphing wing technologies.

Future Trends and Research Directions

Future trends in morphing wing technology emphasize adaptive aerodynamic efficiency through real-time shape alterations, enhancing fuel economy and maneuverability beyond fixed wing capabilities. Research directions prioritize integrating smart materials like shape memory alloys and advanced computational algorithms for precise control and durability under varying flight conditions. Studies also explore hybrid configurations combining morphing and fixed wing elements to optimize performance across diverse mission profiles.

Adaptive aerostructures

Morphing wings equipped with adaptive aerostructures dynamically alter shape to optimize aerodynamic performance and fuel efficiency, outperforming traditional fixed wings with static configurations.

Variable geometry

Variable geometry in morphing wings enables dynamic shape adaptation for optimized aerodynamics and fuel efficiency, unlike fixed wings with static structures.

Shape memory alloys

Shape memory alloys enable morphing wings to adapt their aerodynamic profile in real-time, offering enhanced fuel efficiency and maneuverability compared to traditional fixed-wing designs.

Wing morphing actuation

Wing morphing actuation utilizes advanced materials and smart actuators to dynamically alter wing shape, enhancing aerodynamic efficiency and maneuverability compared to fixed-wing designs.

Aeroelastic tailoring

Morphing wings leverage aeroelastic tailoring to dynamically adjust wing shape for optimized aerodynamic performance and structural efficiency, unlike fixed wings that rely on static designs.

Load alleviation

Morphing wings significantly enhance load alleviation by adapting their shape in real-time to distribute aerodynamic forces more evenly compared to fixed wings.

Compliant mechanisms

Compliant mechanisms enhance morphing wing designs by enabling smooth, continuous shape changes without traditional joints, offering aerodynamic efficiency and structural flexibility superior to fixed-wing configurations.

Smart materials integration

Smart materials integration in morphing wings enables adaptive shape changes for enhanced aerodynamic efficiency, outperform fixed wings with static structures in fuel savings and maneuverability.

High-lift devices

Morphing wings enhance high-lift performance through adaptive shape changes, enabling improved lift-to-drag ratios compared to traditional fixed wings with static high-lift devices.

Spanwise flexibility

Spanwise flexibility in morphing wings enables adaptive aerodynamic performance and improved efficiency compared to the rigid structure of fixed wings.

morphing wing vs fixed wing Infographic

njnir.com

njnir.com