Liquid rocket engines offer precise thrust control and can be throttled, stopped, and restarted, making them ideal for complex space missions requiring variable propulsion. Solid rocket motors provide simplicity, high reliability, and greater thrust-to-weight ratio but lack the ability to adjust thrust once ignited. The choice between liquid and solid propulsion depends on mission requirements such as duration, maneuverability, and payload capacity.

Table of Comparison

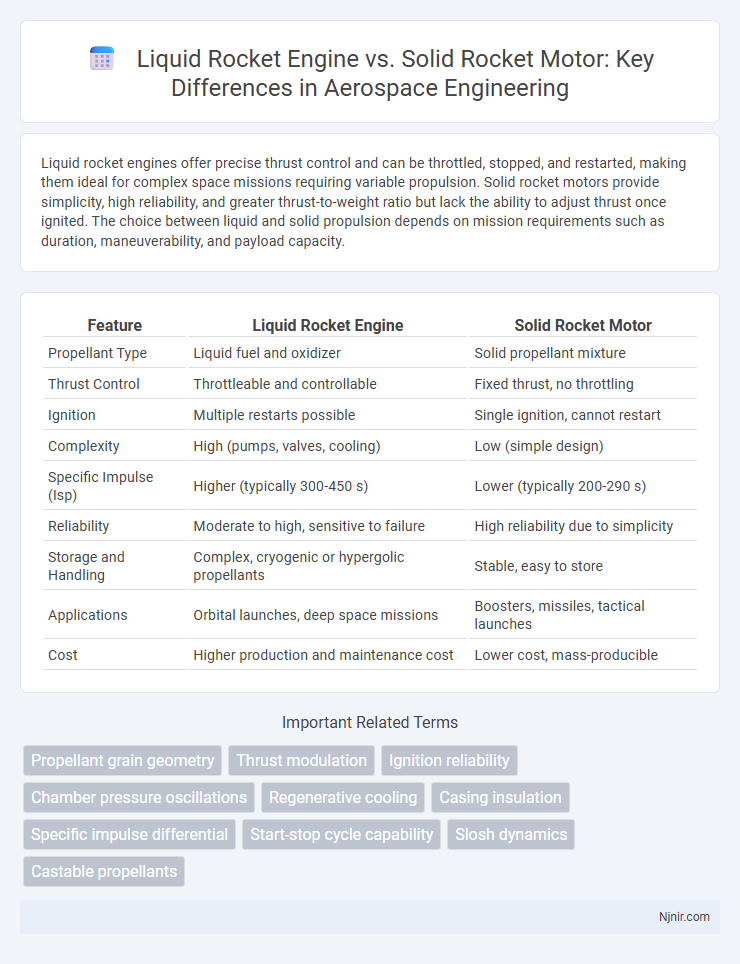

| Feature | Liquid Rocket Engine | Solid Rocket Motor |

|---|---|---|

| Propellant Type | Liquid fuel and oxidizer | Solid propellant mixture |

| Thrust Control | Throttleable and controllable | Fixed thrust, no throttling |

| Ignition | Multiple restarts possible | Single ignition, cannot restart |

| Complexity | High (pumps, valves, cooling) | Low (simple design) |

| Specific Impulse (Isp) | Higher (typically 300-450 s) | Lower (typically 200-290 s) |

| Reliability | Moderate to high, sensitive to failure | High reliability due to simplicity |

| Storage and Handling | Complex, cryogenic or hypergolic propellants | Stable, easy to store |

| Applications | Orbital launches, deep space missions | Boosters, missiles, tactical launches |

| Cost | Higher production and maintenance cost | Lower cost, mass-producible |

Introduction to Liquid Rocket Engines and Solid Rocket Motors

Liquid rocket engines utilize liquid propellants stored in separate tanks, delivering precise thrust control and adjustable burn duration, making them ideal for complex maneuvers and space missions. Solid rocket motors contain pre-mixed solid propellant, offering simplicity, reliability, and high thrust output, suitable for booster stages and military applications. Understanding the distinctions in fuel phase, combustion control, and performance characteristics is crucial for selecting the appropriate propulsion system for specific aerospace requirements.

Fundamental Design Differences

Liquid rocket engines utilize separate tanks for liquid fuel and oxidizer, feeding them into a combustion chamber through complex turbopumps for precise thrust control and throttling. Solid rocket motors store fuel and oxidizer combined in a solid propellant grain, relying on the grain's geometry to control burn rate and typically offering simpler, more robust design with limited thrust modulation. The fundamental distinction lies in propellant phase and feed system complexity, influencing performance flexibility and manufacturing processes.

Propellant Types and Storage

Liquid rocket engines utilize cryogenic or hypergolic propellants stored separately in tanks, allowing precise mixture ratio control and restart capability during flight. Solid rocket motors contain a pre-mixed solid propellant grain within a motor casing, providing simpler storage but no throttle control once ignited. The choice between liquid and solid propellants impacts engine performance, handling complexity, and mission flexibility.

Performance and Efficiency Comparison

Liquid rocket engines offer higher specific impulse, typically ranging between 300 and 450 seconds, which translates to superior fuel efficiency and better performance in terms of thrust control and restart capability. Solid rocket motors possess simpler design and higher thrust-to-weight ratios but generally provide lower specific impulse, around 250 to 300 seconds, resulting in less efficiency and limited throttle control. The performance advantage of liquid engines makes them ideal for missions requiring precise maneuvering and extended burns, whereas solid motors excel in applications needing reliability and rapid deployment.

Thrust Control and Modulation Capabilities

Liquid rocket engines offer precise thrust control and modulation through adjustable propellant flow rates, enabling variable thrust levels and engine throttling during flight. Solid rocket motors lack this flexibility as their thrust is fixed once ignited, with no means to throttle, stop, or restart the engine. This makes liquid engines preferable for missions requiring fine-tuned thrust adjustments and prolonged engine burns.

Reliability and Safety Considerations

Liquid rocket engines offer enhanced reliability through throttle control and the ability to shut down or restart mid-flight, reducing risks during missions. Solid rocket motors, while simpler and more robust due to fewer moving parts, pose higher safety concerns because once ignited, they cannot be stopped or controlled, increasing hazards during handling and operation. Safety protocols for liquid engines are more complex but allow for emergency interventions, whereas solid motors require stringent manufacturing and storage procedures to prevent accidental ignition.

Complexity and Manufacturing Challenges

Liquid rocket engines involve intricate plumbing systems, turbopumps, and combustion chambers, requiring precise engineering and advanced manufacturing techniques to ensure reliable performance under extreme conditions. Solid rocket motors present fewer moving parts but demand specialized fabrication processes to cast homogeneous propellant grain, control burn rates, and prevent cracks that could cause catastrophic failure. Manufacturing liquid engines necessitates rigorous quality control for components subjected to high thermal and mechanical stresses, while solid motors emphasize propellant chemistry uniformity and structural integrity throughout the motor casing.

Cost Analysis and Economic Implications

Liquid rocket engines generally involve higher initial development and manufacturing costs due to complex components and fueling infrastructure, whereas solid rocket motors offer lower production expenses and simpler storage, making them more cost-efficient for short-term or single-use missions. Lifecycle costs for liquid engines can be reduced through reusability and throttle control, enabling multiple missions and operational flexibility, which solid motors lack due to their fixed thrust profiles. Economic implications favor solid motors for budget-sensitive launches requiring quick deployment, while liquid engines provide better cost-effectiveness in long-duration or reusable spacecraft programs where performance and adaptability justify the investment.

Applications in Space Missions and Launch Vehicles

Liquid rocket engines offer precise thrust control and can be throttled, restarted, and shut down, making them ideal for orbital maneuvers, deep space missions, and core stages of launch vehicles such as the Space Launch System (SLS) and Falcon 9. Solid rocket motors provide high thrust at liftoff with a simpler design and are commonly used for initial booster stages in launch vehicles like the Space Shuttle solid boosters and Atlas V's solid strap-ons. The complementary use of liquid engines and solid motors enhances mission flexibility, balancing reliability, cost, and performance across diverse space missions.

Future Trends in Rocket Propulsion Technologies

Future trends in rocket propulsion technologies emphasize the development of advanced liquid rocket engines featuring enhanced reusability, higher specific impulse, and improved throttling capabilities to optimize mission versatility and efficiency. Innovations in green propellants and hybrid propulsion systems aim to reduce environmental impact while maintaining high performance, bridging the gap between traditional solid rocket motors and liquid engines. Emerging materials and additive manufacturing techniques enable lighter, more durable engine components, accelerating the evolution of both liquid and solid propulsion systems for next-generation space exploration.

Propellant grain geometry

Liquid rocket engines utilize fluid propellants stored in separate tanks allowing adjustable flow rates, while solid rocket motors rely on fixed propellant grain geometry shaping combustion surface area to control thrust profiles.

Thrust modulation

Liquid rocket engines provide precise thrust modulation through adjustable propellant flow rates, whereas solid rocket motors offer fixed thrust profiles due to their unchangeable solid propellant composition.

Ignition reliability

Liquid rocket engines offer higher ignition reliability due to precise throttle control and multiple restart capabilities compared to solid rocket motors' single-use, less controllable ignition system.

Chamber pressure oscillations

Liquid rocket engines experience lower chamber pressure oscillations compared to solid rocket motors due to more precise propellant flow control and combustion stability mechanisms.

Regenerative cooling

Liquid rocket engines utilize regenerative cooling by circulating propellant through cooling channels around the combustion chamber, preventing overheating and enhancing efficiency, whereas solid rocket motors lack this cooling mechanism, relying primarily on insulation to manage thermal loads.

Casing insulation

Liquid rocket engines require advanced, lightweight casing insulation to manage high thermal loads and maintain structural integrity, while solid rocket motors use thicker, often ablative insulation to protect the casing from intense combustion heat and pressure.

Specific impulse differential

Liquid rocket engines typically achieve higher specific impulse values ranging from 300 to 450 seconds compared to solid rocket motors, which generally deliver specific impulses between 200 and 300 seconds.

Start-stop cycle capability

Liquid rocket engines offer superior start-stop cycle capability compared to solid rocket motors, enabling precise thrust control and multiple restarts during missions.

Slosh dynamics

Liquid rocket engines exhibit complex slosh dynamics due to propellant fluid movement in tanks, affecting stability and control, whereas solid rocket motors experience minimal slosh-related issues because their propellant is fixed and immobile.

Castable propellants

Liquid rocket engines using castable liquid propellants offer adjustable thrust and restart capability, unlike solid rocket motors that rely on fixed solid fuels for simpler, less controllable combustion.

liquid rocket engine vs solid rocket motor Infographic

njnir.com

njnir.com