Plug nozzles offer enhanced altitude adaptability by adjusting the flow expansion over a contoured plug, improving thrust efficiency across varying atmospheric pressures. Expansion-deflection nozzles achieve variable performance by modifying the flow path through a movable centerbody, allowing precise control of exhaust expansion and shock patterns. Both designs optimize propulsion efficiency for aerospace applications, but plug nozzles generally provide smoother transitions and better off-design performance at different flight regimes.

Table of Comparison

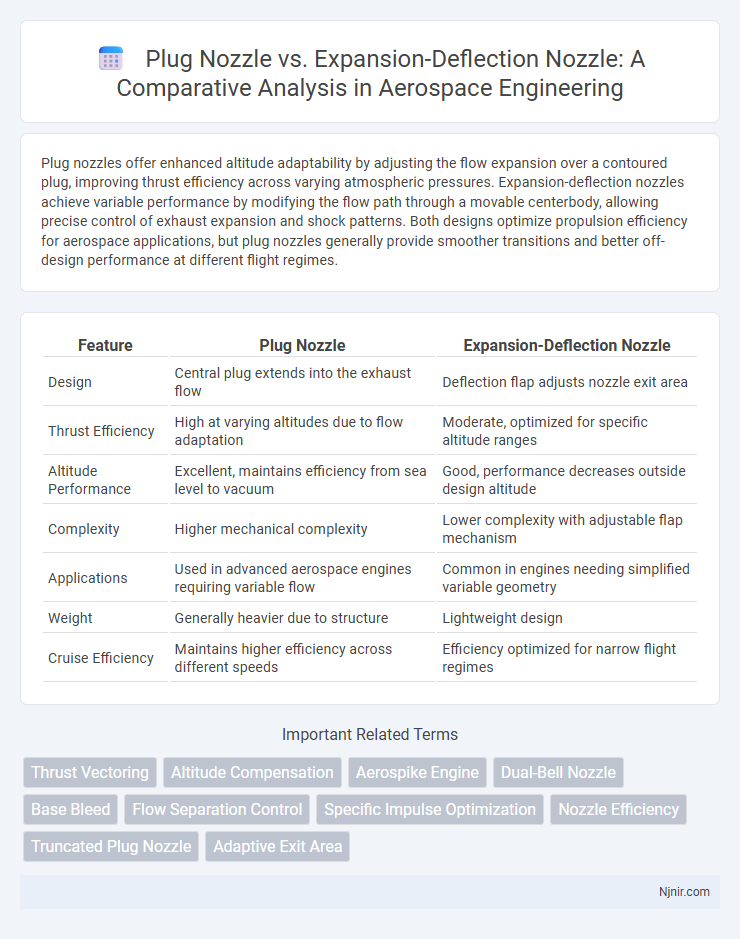

| Feature | Plug Nozzle | Expansion-Deflection Nozzle |

|---|---|---|

| Design | Central plug extends into the exhaust flow | Deflection flap adjusts nozzle exit area |

| Thrust Efficiency | High at varying altitudes due to flow adaptation | Moderate, optimized for specific altitude ranges |

| Altitude Performance | Excellent, maintains efficiency from sea level to vacuum | Good, performance decreases outside design altitude |

| Complexity | Higher mechanical complexity | Lower complexity with adjustable flap mechanism |

| Applications | Used in advanced aerospace engines requiring variable flow | Common in engines needing simplified variable geometry |

| Weight | Generally heavier due to structure | Lightweight design |

| Cruise Efficiency | Maintains higher efficiency across different speeds | Efficiency optimized for narrow flight regimes |

Introduction to Plug Nozzles and Expansion-Deflection Nozzles

Plug nozzles use an inner plug to shape exhaust flow, increasing efficiency by controlling expansion within the nozzle exit. Expansion-deflection nozzles employ a movable flap or disc to adjust the flow area, allowing for optimal expansion across varying altitudes and improving thrust performance. Both nozzle types enhance rocket engine efficiency by managing exhaust flow expansion more effectively than conventional bell nozzles.

Historical Development and Applications

The plug nozzle, developed during the mid-20th century, was initially designed for supersonic aircraft and missile propulsion, providing altitude-compensating exhaust flow for improved performance. Expansion-deflection nozzles emerged later as a refinement, offering enhanced thrust efficiency and controllability by adjusting the flow separation point within the nozzle, widely utilized in advanced rocket engines and space launch systems. Both nozzles represent critical advancements in aerospace propulsion, with plug nozzles favored in reusable spaceplanes and expansion-deflection nozzles increasingly adopted in variable-thrust rocket engines.

Fundamental Operating Principles

Plug nozzles operate by employing a centerbody that creates a variable flow area, allowing the exhaust gases to expand and accelerate around the plug, optimizing thrust across a range of altitudes through shock wave control. Expansion-deflection nozzles utilize a deflecting surface at the throat that adjusts the exhaust flow expansion by altering the flow path, maintaining efficient performance by managing shock wave position and pressure distribution with altitude changes. Both nozzles modulate exhaust flow geometry to maximize propulsion efficiency, but plug nozzles rely on a fixed centerbody shape while expansion-deflection nozzles adjust flow deflection dynamically.

Aerodynamic Performance Comparisons

Plug nozzles exhibit superior altitude adaptation and maintain higher thrust efficiency across a wide range of operating conditions compared to expansion-deflection nozzles, which often experience flow separation and shock wave formation at off-design points. The plug nozzle's continuous contour enables smoother expansion of exhaust gases, reducing drag and improving overall propulsion system performance. Expansion-deflection nozzles, while simpler in design, generally have lower specific impulse and suffer from increased aerodynamic losses during transonic to supersonic transitions.

Thrust Vectoring and Control Capabilities

Plug nozzles provide enhanced thrust vectoring capabilities through movable centerbodies that allow variable flow deflection, enabling precise flight control and improved maneuverability. Expansion-deflection nozzles achieve thrust vectoring by altering the geometry of the divergent section, but their control range and flexibility are generally more limited compared to plug nozzles. Both nozzle types offer improved control for high-altitude and variable nozzle pressure ratio conditions, with plug nozzles typically delivering superior adaptability in dynamic thrust vectoring applications.

Efficiency Across Altitude Ranges

Plug nozzles maintain higher efficiency across a wide range of altitudes by adapting the exhaust flow to external pressure changes, reducing flow separation and shock losses. Expansion-deflection nozzles optimize performance by controlling the flow expansion and deflection to match varying ambient pressures, but typically exhibit less stable efficiency compared to plug nozzles at extreme altitudes. Both nozzle types improve altitude compensation over traditional bell nozzles, yet plug nozzles generally offer superior overall efficiency from sea level to vacuum conditions.

Structural Design Considerations

Plug nozzles feature a central plug that deflects exhaust flow, requiring robust structural support to withstand high thermal and mechanical stresses at the plug base and lip. Expansion-deflection nozzles utilize a flared divergent section to control exhaust expansion, demanding careful material selection and reinforcement to handle thermal gradients and pressure loads without compromising nozzle contour integrity. Both designs necessitate meticulous analysis of thermal expansion, vibration, and material fatigue to ensure optimal performance and durability in high-temperature propulsion environments.

Integration with Propulsion Systems

Plug nozzles offer improved altitude performance by maintaining efficient expansion across varying atmospheric pressures, making them highly compatible with variable-thrust rocket engines and air-breathing propulsion systems. Expansion-deflection nozzles provide enhanced thrust vector control and simplified integration with fixed-geometry engines, optimizing performance in both subsonic and supersonic flight regimes. Both nozzle types are designed to maximize propulsion efficiency, but plug nozzles tend to require more complex integration due to their adjustable geometry components.

Challenges in Manufacturing and Maintenance

Plug nozzles present manufacturing challenges due to their complex geometry, requiring precise machining and advanced materials to withstand high thermal and mechanical stresses. Expansion-deflection nozzles face difficulties in maintaining structural integrity under fluctuating pressure and temperature conditions, often demanding specialized inspection techniques and frequent component replacement. Both nozzle types necessitate rigorous quality control and tailored maintenance protocols to ensure operational reliability in aerospace propulsion systems.

Future Trends and Research Directions

Future trends in nozzle technology emphasize increased efficiency and adaptability in plug nozzles and expansion-deflection nozzles, driven by advancements in computational fluid dynamics and additive manufacturing. Research directions focus on optimizing thrust vectoring capabilities, thermal management, and material resilience to withstand extreme aerospace environments. Integration of smart materials and real-time adaptive controls shows potential to revolutionize nozzle performance in next-generation propulsion systems.

Thrust Vectoring

Plug nozzles offer efficient thrust vectoring with simpler mechanical design and rapid response for high-speed aircraft, while expansion-deflection nozzles provide enhanced vectoring angle control and improved performance at varying altitudes.

Altitude Compensation

Plug nozzles maintain optimal thrust across varying altitudes by adjusting exhaust flow around a central plug, whereas expansion-deflection nozzles achieve altitude compensation by shifting the shock structure within the nozzle, enabling efficient performance over a wide range of ambient pressures.

Aerospike Engine

Aerospike engines outperform traditional plug and expansion-deflection nozzles by maintaining optimal thrust efficiency across varying altitudes through altitude-compensating nozzle designs that minimize flow separation and drag.

Dual-Bell Nozzle

The Dual-Bell Nozzle combines features of Plug and Expansion-Deflection Nozzles by using a contour that shifts between two expansion modes to optimize performance across varying atmospheric pressures.

Base Bleed

Base bleed in plug nozzles reduces base drag by injecting gas into the base flow region, while expansion-deflection nozzles manage base pressure through controlled expansion, enhancing overall thrust efficiency.

Flow Separation Control

Plug nozzles minimize flow separation through controlled boundary layer adherence, whereas expansion-deflection nozzles use deflected flow paths to actively manage and delay separation, enhancing thrust efficiency.

Specific Impulse Optimization

Plug nozzles optimize specific impulse by maintaining efficient expansion across varying altitudes, while expansion-deflection nozzles achieve specific impulse optimization through adjustable flow deflection that adapts to pressure changes.

Nozzle Efficiency

Expansion-deflection nozzles typically achieve higher nozzle efficiency than plug nozzles by better optimizing flow expansion and reducing shock losses in variable-altitude conditions.

Truncated Plug Nozzle

The truncated plug nozzle offers improved thrust efficiency and reduced weight compared to the expansion-deflection nozzle by optimizing flow expansion within a compact design.

Adaptive Exit Area

The Plug Nozzle offers superior adaptive exit area control compared to the Expansion-Deflection Nozzle, enabling optimized thrust efficiency across varying atmospheric pressures.

Plug Nozzle vs Expansion-Deflection Nozzle Infographic

njnir.com

njnir.com