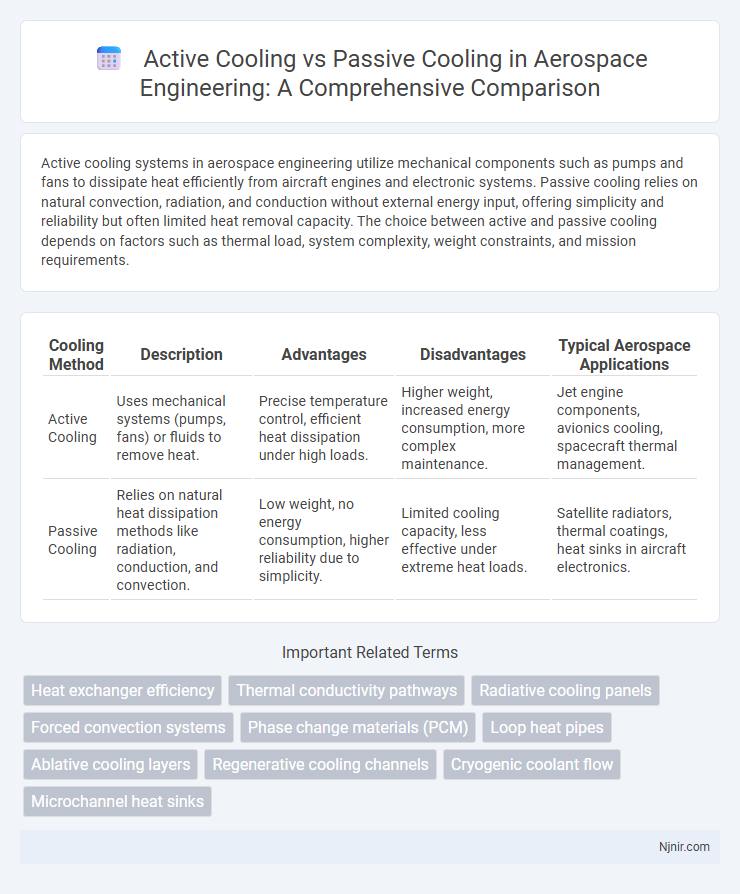

Active cooling systems in aerospace engineering utilize mechanical components such as pumps and fans to dissipate heat efficiently from aircraft engines and electronic systems. Passive cooling relies on natural convection, radiation, and conduction without external energy input, offering simplicity and reliability but often limited heat removal capacity. The choice between active and passive cooling depends on factors such as thermal load, system complexity, weight constraints, and mission requirements.

Table of Comparison

| Cooling Method | Description | Advantages | Disadvantages | Typical Aerospace Applications |

|---|---|---|---|---|

| Active Cooling | Uses mechanical systems (pumps, fans) or fluids to remove heat. | Precise temperature control, efficient heat dissipation under high loads. | Higher weight, increased energy consumption, more complex maintenance. | Jet engine components, avionics cooling, spacecraft thermal management. |

| Passive Cooling | Relies on natural heat dissipation methods like radiation, conduction, and convection. | Low weight, no energy consumption, higher reliability due to simplicity. | Limited cooling capacity, less effective under extreme heat loads. | Satellite radiators, thermal coatings, heat sinks in aircraft electronics. |

Introduction to Cooling in Aerospace Engineering

Active cooling in aerospace engineering relies on mechanical systems such as pumps and fans to dissipate heat generated by aircraft components, enabling precise temperature control and continuous operation under extreme conditions. Passive cooling leverages natural convection, radiation, and conduction without moving parts, providing reliable, maintenance-free heat management but often limited by environmental factors. Combining both methods enhances thermal regulation, critical for maintaining performance and safety in aerospace systems.

Fundamentals of Active Cooling Systems

Active cooling systems rely on mechanical components such as compressors, fans, or pumps to transfer heat away from devices, offering precise temperature control and rapid heat dissipation. These systems utilize refrigerants or electrically driven fluids to absorb and transport heat, enhancing efficiency in high-power electronic environments and climate control applications. Key components include heat exchangers, compressors, and expansion valves, which work in a cycle to maintain consistent cooling performance under varying thermal loads.

Overview of Passive Cooling Techniques

Passive cooling techniques rely on natural heat dissipation methods without external energy input, including strategies such as natural ventilation, thermal mass utilization, shading devices, and evaporative cooling. These methods enhance indoor comfort by reducing heat gain and promoting airflow, leveraging materials like concrete or stone to absorb and slowly release heat. Incorporating green roofs and reflective surfaces further optimizes passive cooling by minimizing solar radiation absorption and facilitating heat reflection.

Key Advantages of Active Cooling

Active cooling offers superior temperature control by using fans or liquid cooling systems to quickly dissipate heat from components, preventing overheating and enhancing performance. It allows for precise regulation of thermal conditions, which is critical in high-power electronics and gaming systems. This method also supports higher system reliability and longer hardware lifespan by maintaining optimal operating temperatures.

Benefits of Passive Cooling Methods

Passive cooling methods reduce energy consumption by eliminating the need for mechanical systems, leading to lower utility bills and decreased carbon footprints. These techniques improve indoor air quality and thermal comfort through natural ventilation, shading, and materials with high thermal mass. Maintaining building durability and minimizing maintenance costs are additional advantages of relying on passive cooling strategies.

Comparative Performance Analysis

Active cooling systems, such as fans and liquid coolers, provide superior heat dissipation rates by actively circulating air or coolant, resulting in lower operating temperatures compared to passive cooling methods. Passive cooling relies on heat sinks, natural convection, and radiation, offering silent operation and reduced maintenance but with limited thermal management efficiency under high load conditions. Performance benchmarks consistently show active cooling achieving up to 30-50% better temperature control in CPUs and GPUs during intensive computational tasks than passive cooling solutions.

Energy Efficiency Considerations

Active cooling systems consume electrical energy to power fans or compressors, which can increase operational costs and carbon footprint, but provide precise temperature control ideal for high-heat environments. Passive cooling relies on natural airflow, thermal mass, and design features like shading and ventilation, reducing energy consumption significantly and enhancing sustainability. Optimal energy efficiency often results from integrating passive methods to minimize load while using active cooling selectively to maintain target temperatures.

Reliability and Maintenance in Aerospace Applications

Active cooling systems in aerospace applications offer high reliability due to precise temperature control but require regular maintenance to ensure pump and fan functionality. Passive cooling methods provide enhanced dependability with fewer mechanical failures, minimizing maintenance needs by relying on natural heat dissipation through heat sinks and thermal coatings. Selecting between active and passive cooling depends on mission-critical reliability requirements and the acceptable level of maintenance during aircraft operation cycles.

Selection Criteria for Cooling Approaches

Selection criteria for active versus passive cooling focus on factors like heat dissipation requirements, device size, and power consumption. Active cooling involves components such as fans or liquid coolants to enhance heat transfer, ideal for high-performance systems with significant thermal loads. Passive cooling relies on heat sinks, natural convection, or radiation, suited for energy-efficient, low-noise applications with moderate heat generation.

Future Trends in Aerospace Thermal Management

Future trends in aerospace thermal management emphasize the integration of hybrid active-passive cooling technologies to enhance efficiency and reliability in extreme environments. Advanced phase change materials and microfluidic cooling systems are being developed to optimize heat dissipation in compact aerospace components. Innovations in nanomaterials and smart sensors enable adaptive thermal control, reducing weight and energy consumption in next-generation aircraft and spacecraft.

Heat exchanger efficiency

Active cooling systems achieve higher heat exchanger efficiency by utilizing powered components to enhance heat transfer rates compared to passive cooling systems relying solely on natural convection and conduction.

Thermal conductivity pathways

Active cooling enhances thermal conductivity pathways by using external energy to increase heat transfer efficiency, while passive cooling relies solely on natural heat dissipation through materials with inherently high thermal conductivity.

Radiative cooling panels

Radiative cooling panels use passive cooling techniques by reflecting sunlight and emitting infrared radiation to dissipate heat, offering energy-efficient alternatives to active cooling systems that rely on mechanical refrigeration.

Forced convection systems

Forced convection systems use external devices like fans or pumps to enhance heat transfer by actively moving air or liquid, providing more efficient and controlled cooling compared to passive cooling methods.

Phase change materials (PCM)

Phase change materials (PCM) enhance passive cooling by absorbing and releasing thermal energy during phase transitions, providing energy-efficient temperature regulation without the need for mechanical systems used in active cooling.

Loop heat pipes

Loop heat pipes provide efficient active cooling by utilizing capillary-driven fluid circulation to transfer heat rapidly, outperforming passive cooling systems that rely solely on conduction and natural convection.

Ablative cooling layers

Ablative cooling layers provide superior thermal protection by actively absorbing and dissipating heat through material erosion, unlike passive cooling which relies solely on conduction and radiation.

Regenerative cooling channels

Regenerative cooling channels enhance active cooling efficiency by continuously circulating coolant through combustion chamber walls, significantly reducing engine temperatures compared to passive cooling methods.

Cryogenic coolant flow

Cryogenic coolant flow enhances active cooling efficiency by rapidly absorbing heat through forced circulation, unlike passive cooling which relies on natural convection and conduction without mechanical assistance.

Microchannel heat sinks

Microchannel heat sinks enable efficient active cooling by rapidly dissipating heat through forced fluid flow, outperforming passive cooling methods that rely solely on natural convection and conduction.

active cooling vs passive cooling Infographic

njnir.com

njnir.com