Cable-driven actuation in aerospace engineering offers lightweight design and reduced maintenance compared to hydraulic actuation, enhancing overall system efficiency and reliability. Cable systems provide precise control with minimal fluid leakage risks, making them ideal for remote and complex flight surfaces. Hydraulic actuation, while powerful and capable of delivering high force, often involves heavier components and increased potential for maintenance challenges due to fluid handling.

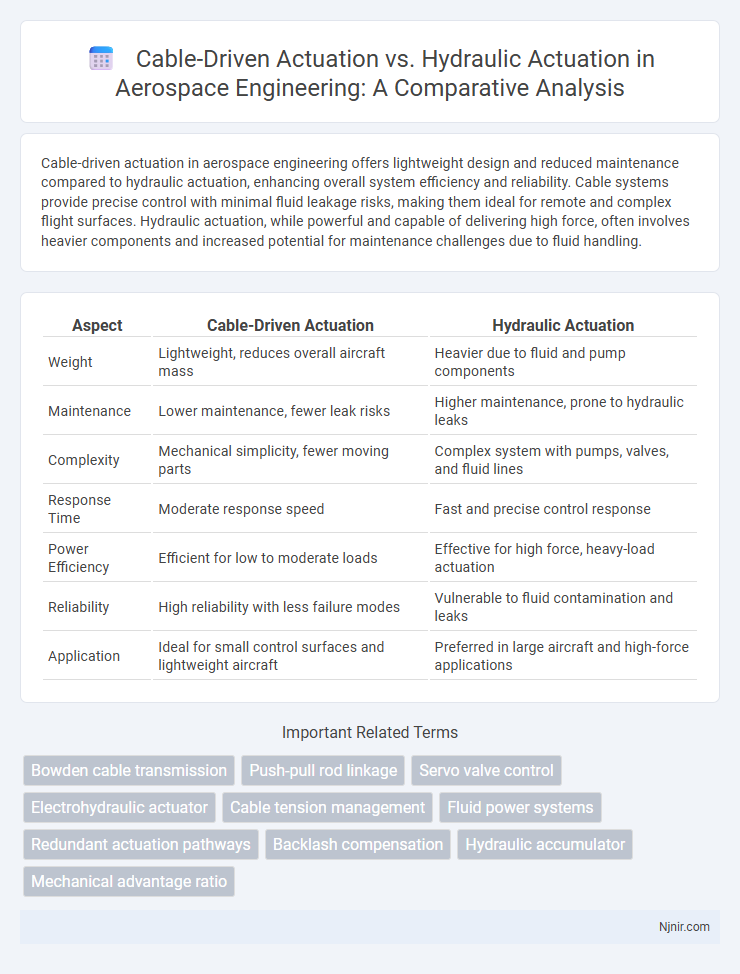

Table of Comparison

| Aspect | Cable-Driven Actuation | Hydraulic Actuation |

|---|---|---|

| Weight | Lightweight, reduces overall aircraft mass | Heavier due to fluid and pump components |

| Maintenance | Lower maintenance, fewer leak risks | Higher maintenance, prone to hydraulic leaks |

| Complexity | Mechanical simplicity, fewer moving parts | Complex system with pumps, valves, and fluid lines |

| Response Time | Moderate response speed | Fast and precise control response |

| Power Efficiency | Efficient for low to moderate loads | Effective for high force, heavy-load actuation |

| Reliability | High reliability with less failure modes | Vulnerable to fluid contamination and leaks |

| Application | Ideal for small control surfaces and lightweight aircraft | Preferred in large aircraft and high-force applications |

Introduction to Aerospace Actuation Systems

Cable-driven actuation systems in aerospace offer lightweight, flexible, and corrosion-resistant solutions ideal for flight control surfaces, reducing overall aircraft weight and enhancing fuel efficiency. Hydraulic actuation systems provide high force density and precise control, making them suitable for heavy-duty tasks like landing gear deployment and flight control on larger aircraft. The choice between cable-driven and hydraulic actuation depends on factors such as load requirements, system complexity, maintenance needs, and reliability under varying flight conditions.

Fundamental Principles of Cable-Driven Actuation

Cable-driven actuation operates on the principle of transmitting force and motion through flexible cables, which convert rotational or linear input into precise mechanical output, offering high efficiency and lightweight design. The system typically uses tensioned cables guided by pulleys to control movement, enabling compliant and adaptable actuation with reduced inertia compared to hydraulic systems. This approach contrasts with hydraulic actuation, which relies on pressurized fluid to generate force, often resulting in bulkier components and complex maintenance.

Overview of Hydraulic Actuation Mechanisms

Hydraulic actuation mechanisms utilize pressurized fluid to generate force and motion, providing high power density and precise control in heavy-duty applications. Components such as pumps, valves, cylinders, and reservoirs work together to convert hydraulic energy into mechanical movement with excellent force amplification. Compared to cable-driven systems, hydraulics offer superior torque output and smooth operation under variable loads, ideal for industrial machinery, construction equipment, and aerospace actuators.

Comparative Analysis: Response Time and Precision

Cable-driven actuation offers faster response times due to lower inertia and reduced fluid compressibility compared to hydraulic actuation, resulting in more immediate and precise control. Hydraulic actuation, while capable of generating higher forces, often experiences delays from fluid dynamics and valve response, which can compromise rapid precision tasks. The low backlash and direct mechanical linkage of cable-driven systems enhance positioning accuracy, making them ideal for applications demanding swift and exact movements.

Weight and Space Considerations in Aircraft Systems

Cable-driven actuation systems offer significant weight savings compared to hydraulic actuation, reducing the need for heavy fluid reservoirs, pumps, and extensive plumbing. Space efficiency is enhanced in cable-driven setups due to their compact routing capabilities within the aircraft structure, minimizing fuselage volume usage. Hydraulic actuation demands larger components and maintenance access points, increasing both aircraft weight and occupied space, impacting fuel efficiency and payload capacity.

Reliability and Maintenance Demands

Cable-driven actuation systems offer enhanced reliability due to fewer moving parts and reduced risk of leakage compared to hydraulic systems, which rely on fluid dynamics and seals prone to wear and failure. Maintenance demands for cable-driven actuators are generally lower, involving routine inspection and tension adjustments, whereas hydraulic actuators require regular fluid checks, seal replacements, and potential leak repairs. The simplicity and mechanical durability of cable-driven systems make them preferable in environments where reliability and minimal maintenance are critical.

Safety and Failure Modes

Cable-driven actuation offers enhanced safety through lower risk of fluid leaks and explosions compared to hydraulic systems, which rely on pressurized fluids prone to leaks that can cause slippery surfaces or fire hazards. Failure modes in cable-driven systems typically involve cable wear or breakage, which can be detected and prevented with regular maintenance, whereas hydraulic failures can lead to sudden loss of control due to fluid pressure loss. The redundancy and easier inspection of cable-driven actuators contribute to safer operation in critical applications like medical robotics and aerospace.

Integration with Avionics and Control Architectures

Cable-driven actuation offers seamless integration with avionics and control architectures due to its lightweight design and reduced electromagnetic interference, enabling precise signal transmission and responsiveness. Hydraulic actuation systems, while powerful, often require bulky components and complex routing that can complicate integration and increase system maintenance. Advanced control algorithms capitalize on cable-driven actuation's direct mechanical linkages for enhanced feedback accuracy and real-time adjustments in modern avionics systems.

Environmental and Operational Suitability

Cable-driven actuation offers superior environmental suitability due to its low risk of fluid leaks and reduced need for hazardous hydraulic oils, making it ideal for clean and sensitive environments. Its operational suitability includes lightweight and compact design, enabling precise control with minimal maintenance requirements, especially in confined spaces. Hydraulic actuation provides high force output and robustness for heavy-duty applications but demands rigorous maintenance and poses environmental risks from potential oil spills and contamination.

Future Trends in Aerospace Actuation Technologies

Cable-driven actuation systems are gaining prominence in aerospace due to their lightweight design, enhanced precision, and reduced maintenance compared to traditional hydraulic actuation systems. Hydraulic actuation remains favored for high-force applications but faces challenges related to fluid leakage, system complexity, and weight penalties. Future trends emphasize the integration of smart materials, advanced sensor fusion, and electrification in cable-driven actuation to improve reliability, energy efficiency, and system adaptability in aerospace applications.

Bowden cable transmission

Bowden cable transmission in cable-driven actuation offers precise, lightweight force transmission with reduced leakage and maintenance compared to bulky hydraulic actuation systems.

Push-pull rod linkage

Push-pull rod linkage in cable-driven actuation offers lightweight, precise, and low-maintenance motion transfer compared to the high force density and power of hydraulic actuation systems.

Servo valve control

Cable-driven actuation offers precise positioning with minimal hydraulic fluid leakage risks, whereas hydraulic actuation with servo valve control delivers higher force output and faster dynamic response for heavy-duty applications.

Electrohydraulic actuator

Electrohydraulic actuators combine the precision of electric control with the high force density of hydraulic actuation, offering superior responsiveness and efficiency compared to cable-driven systems.

Cable tension management

Cable-driven actuation offers precise cable tension management through adjustable tensioners and low friction operation, enhancing control accuracy compared to the complex pressure regulation required in hydraulic actuation.

Fluid power systems

Cable-driven actuation offers lightweight, flexible motion control with reduced fluid leakage risk, whereas hydraulic actuation in fluid power systems provides higher force density and precise power transmission for heavy-duty applications.

Redundant actuation pathways

Cable-driven actuation offers inherently redundant actuation pathways through multiple cable lines enabling fault tolerance, whereas hydraulic actuation redundancy requires complex parallel circuits and backup pumps to ensure system reliability.

Backlash compensation

Cable-driven actuators provide more precise backlash compensation than hydraulic actuators due to their lower compliance and friction levels.

Hydraulic accumulator

Hydraulic actuation with a hydraulic accumulator provides consistent pressure regulation and energy storage for efficient power delivery compared to cable-driven actuation.

Mechanical advantage ratio

Cable-driven actuation offers a higher mechanical advantage ratio with reduced weight and increased flexibility compared to the typically heavier and less adaptable hydraulic actuation systems.

cable-driven actuation vs hydraulic actuation Infographic

njnir.com

njnir.com