Fly-by-wire systems in aerospace engineering replace traditional hydraulic controls with electronic interfaces, enhancing precision and reducing weight. These digital systems improve aircraft responsiveness by processing pilot inputs through computer algorithms, offering adaptive flight control capabilities. Maintenance requirements and system reliability are also optimized, making fly-by-wire a preferred choice for modern aircraft design.

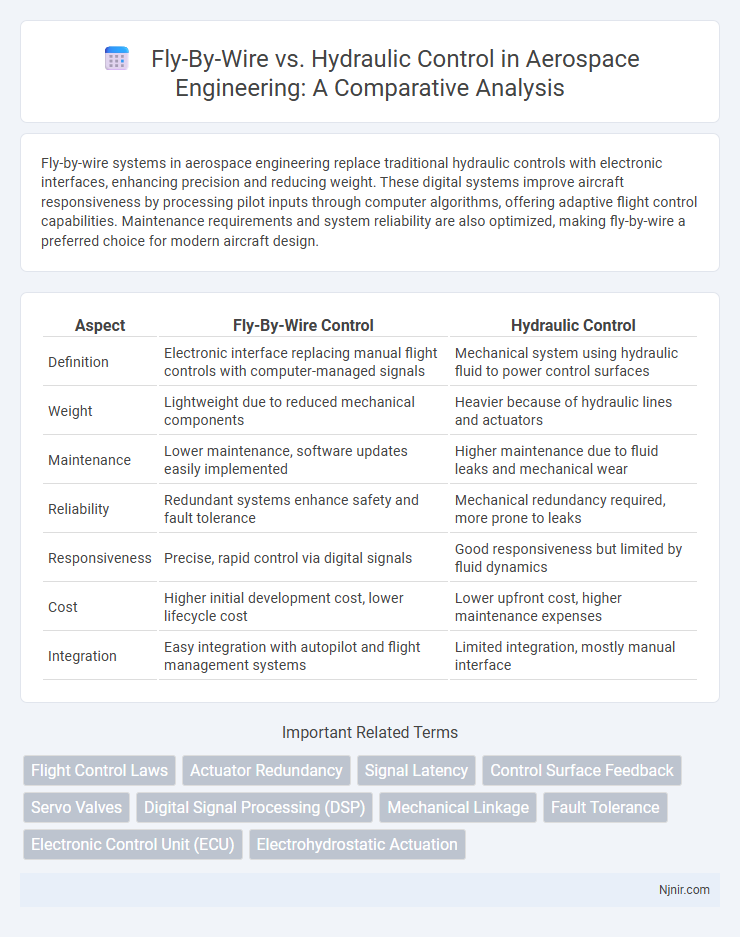

Table of Comparison

| Aspect | Fly-By-Wire Control | Hydraulic Control |

|---|---|---|

| Definition | Electronic interface replacing manual flight controls with computer-managed signals | Mechanical system using hydraulic fluid to power control surfaces |

| Weight | Lightweight due to reduced mechanical components | Heavier because of hydraulic lines and actuators |

| Maintenance | Lower maintenance, software updates easily implemented | Higher maintenance due to fluid leaks and mechanical wear |

| Reliability | Redundant systems enhance safety and fault tolerance | Mechanical redundancy required, more prone to leaks |

| Responsiveness | Precise, rapid control via digital signals | Good responsiveness but limited by fluid dynamics |

| Cost | Higher initial development cost, lower lifecycle cost | Lower upfront cost, higher maintenance expenses |

| Integration | Easy integration with autopilot and flight management systems | Limited integration, mostly manual interface |

Introduction to Aircraft Control Systems

Fly-by-wire systems replace traditional hydraulic controls with electronic interfaces, offering enhanced precision and reduced weight in aircraft control systems. These systems use digital signals to transmit pilot inputs directly to actuators, improving response time and system reliability. Hydraulic controls, while historically prevalent due to their power density and robustness, face limitations in maintenance complexity and weight compared to modern fly-by-wire technology.

Evolution of Flight Control Technologies

Fly-by-wire systems revolutionized flight control by replacing traditional hydraulic linkages with electronic signals, improving aircraft responsiveness and reducing weight. Hydraulic controls, dominant in early aviation for their robustness and mechanical reliability, gradually gave way to digital fly-by-wire due to advancements in sensor accuracy and computer processing power. Modern flight control technologies integrate redundant electronic systems and adaptive algorithms, enhancing safety, precision, and overall aerodynamic efficiency compared to purely hydraulic setups.

Fundamentals of Hydraulic Control Systems

Hydraulic control systems rely on pressurized fluid to actuate mechanical components, providing high power density and precise force control. The fundamentals include components such as pumps, valves, actuators, and fluid reservoirs, which work in a closed-loop to transfer energy efficiently from the hydraulic fluid to control surfaces. Compared to fly-by-wire systems that use electronic signals for control input transmission, hydraulic systems offer robust, fail-safe mechanical feedback and are widely utilized in traditional aircraft for primary flight control due to their reliability under extreme conditions.

Principles of Fly-By-Wire Systems

Fly-by-wire systems replace traditional hydraulic controls with electronic signals for aircraft operation, enhancing precision and reducing weight. They use sensors, computers, and actuators to interpret pilot input and adjust control surfaces dynamically, enabling real-time feedback and fault-tolerant redundancy. This electronic architecture improves safety and allows for complex flight envelope protection not achievable with purely hydraulic systems.

Key Components: Hydraulics vs. Electronics

Fly-by-wire systems rely on electronic sensors, digital computers, and actuators to control aircraft movements, replacing traditional mechanical linkages with electrical signals. Hydraulic control systems depend on pumps, fluid-filled lines, actuators, and valves to transmit pilot commands through pressurized fluid, providing direct mechanical force to control surfaces. Key components in fly-by-wire include flight control computers and electrical wiring, while hydraulics emphasize pumps, reservoirs, fluid lines, and servo valves for control actuation.

Safety and Reliability Comparisons

Fly-by-wire systems enhance safety through multiple redundancy layers and real-time computer monitoring, significantly reducing pilot error and mechanical failure risks compared to traditional hydraulic controls. Hydraulic control systems rely on mechanical components prone to wear, leaks, and failure, which can compromise reliability during critical operations. Advanced diagnostics and fault-tolerant architectures in fly-by-wire technology ensure continuous, stable control under adverse conditions, outperforming hydraulic counterparts in operational safety and system dependability.

Advantages of Fly-By-Wire Control

Fly-by-wire control systems offer significant advantages over traditional hydraulic control, including reduced aircraft weight due to the elimination of heavy mechanical linkages and hydraulic components. Enhanced flight safety is achieved through advanced computer algorithms that provide real-time system monitoring, fault detection, and automatic stability augmentation. Moreover, fly-by-wire systems enable greater design flexibility, smoother control responses, and lower maintenance costs compared to hydraulic control systems.

Limitations of Hydraulic Systems

Hydraulic control systems face limitations such as susceptibility to leaks, resulting in potential fluid loss and reduced performance. These systems also require complex maintenance due to numerous mechanical components prone to wear and corrosion. Furthermore, hydraulic controls add significant weight to aircraft, impacting fuel efficiency and overall operational costs.

Integration in Modern Aircraft Design

Fly-by-wire systems have become integral in modern aircraft design by replacing traditional hydraulic controls with electronic interfaces that enhance precision and reduce weight. Integration of fly-by-wire allows for advanced flight control algorithms, improved system redundancy, and real-time data processing, enabling safer and more efficient operation. Hydraulic systems remain critical for backup and high-force applications, but fly-by-wire technology drives innovation in cockpit integration and overall aircraft performance.

Future Trends in Flight Control Technology

Future trends in flight control technology emphasize the increasing integration of fly-by-wire (FBW) systems due to their enhanced reliability, weight reduction, and improved fuel efficiency compared to traditional hydraulic controls. Advances in artificial intelligence and machine learning are enabling adaptive control algorithms within FBW systems, offering real-time optimization and fault tolerance. Hybrid architectures combining fly-by-wire with backup hydraulic actuators are emerging to balance safety and performance in next-generation aircraft.

Flight Control Laws

Flight control laws in fly-by-wire systems continuously process pilot inputs through computers to optimize aircraft stability and performance, whereas hydraulic controls rely on direct mechanical linkages with limited adaptive response.

Actuator Redundancy

Fly-by-wire systems enhance actuator redundancy by utilizing multiple independent electronic channels to ensure continuous control, whereas hydraulic controls rely on mechanical backups prone to failure under extreme conditions.

Signal Latency

Fly-by-wire systems reduce signal latency compared to hydraulic controls by transmitting electronic signals instantly rather than relying on slower hydraulic fluid pressure changes.

Control Surface Feedback

Fly-by-wire systems provide precise control surface feedback through electronic sensors and actuators, enhancing responsiveness and reducing pilot workload compared to traditional hydraulic control, which relies on mechanical linkages and fluid pressure for feedback.

Servo Valves

Servo valves in fly-by-wire systems offer precise, electronically controlled fluid flow compared to the mechanically actuated valves in traditional hydraulic control, enhancing responsiveness and reliability.

Digital Signal Processing (DSP)

Fly-by-wire systems leverage advanced Digital Signal Processing (DSP) to enhance control precision, reduce weight, and improve system reliability compared to traditional hydraulic control systems.

Mechanical Linkage

Mechanical linkage in hydraulic control systems uses direct physical connections for pilot input transmission, whereas fly-by-wire replaces these linkages with electronic signals, enhancing precision and reducing mechanical complexity.

Fault Tolerance

Fly-by-wire systems enhance fault tolerance by using multiple redundant digital channels and automatic error detection, whereas hydraulic controls rely on mechanical redundancy and manual overrides to maintain operation during failures.

Electronic Control Unit (ECU)

The Electronic Control Unit (ECU) in fly-by-wire systems enhances aircraft control precision and safety by replacing traditional hydraulic controls with computerized signal processing and real-time feedback.

Electrohydrostatic Actuation

Electrohydrostatic actuation combines the reliability of hydraulic control with the precision and efficiency of fly-by-wire systems by using electrically driven hydraulic pumps for independent actuation and improved fault tolerance.

fly-by-wire vs hydraulic control Infographic

njnir.com

njnir.com