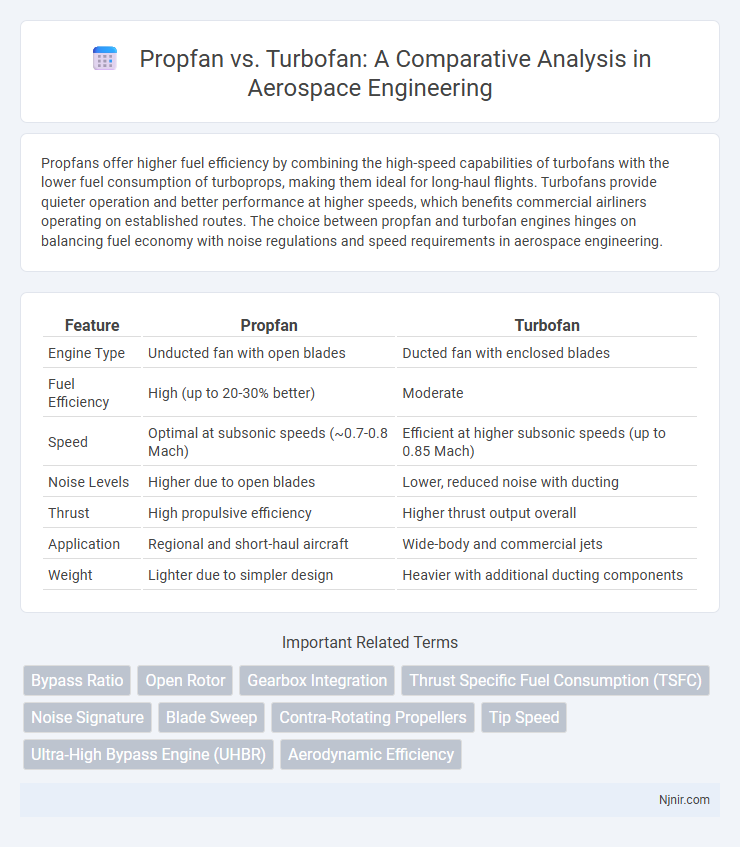

Propfans offer higher fuel efficiency by combining the high-speed capabilities of turbofans with the lower fuel consumption of turboprops, making them ideal for long-haul flights. Turbofans provide quieter operation and better performance at higher speeds, which benefits commercial airliners operating on established routes. The choice between propfan and turbofan engines hinges on balancing fuel economy with noise regulations and speed requirements in aerospace engineering.

Table of Comparison

| Feature | Propfan | Turbofan |

|---|---|---|

| Engine Type | Unducted fan with open blades | Ducted fan with enclosed blades |

| Fuel Efficiency | High (up to 20-30% better) | Moderate |

| Speed | Optimal at subsonic speeds (~0.7-0.8 Mach) | Efficient at higher subsonic speeds (up to 0.85 Mach) |

| Noise Levels | Higher due to open blades | Lower, reduced noise with ducting |

| Thrust | High propulsive efficiency | Higher thrust output overall |

| Application | Regional and short-haul aircraft | Wide-body and commercial jets |

| Weight | Lighter due to simpler design | Heavier with additional ducting components |

Introduction to Propfan and Turbofan Technologies

Propfan technology combines the efficiency of a propeller with the speed capabilities of a turbofan engine by using highly swept, unducted fan blades operating at high speeds. Turbofan engines, featuring ducted fans, dominate commercial aviation with their balance of thrust, fuel efficiency, and noise reduction. Understanding the aerodynamic principles and mechanical designs behind propfans and turbofans is essential to evaluating their respective performance advantages for modern aircraft propulsion.

Historical Development of Propfan and Turbofan Engines

The historical development of turbofan engines began in the 1940s with the introduction of bypass technology to improve fuel efficiency and reduce noise compared to turbojets, leading to widespread adoption in commercial aviation by the 1960s. Propfan engines, emerging prominently in the late 1970s and 1980s, combined features of turboprops and turbofans, offering high-speed propeller propulsion with advanced composite blades to enhance fuel efficiency during the fuel crises era. Both engine types reflect continuous innovation aimed at balancing thrust, fuel economy, and noise reduction across different flight regimes.

Principle of Operation: Propfan vs Turbofan

Propfans operate by combining the high-speed capabilities of turbofans with the efficient large-diameter propellers driven by a gas turbine, utilizing unducted, contra-rotating blades to generate thrust through accelerated airflow. Turbofans generate thrust by drawing air through a large fan enclosed in a duct, where a portion of the air bypasses the engine core, resulting in improved fuel efficiency and quieter operation. The core difference in principle lies in the propfan's open rotor design aimed at maximizing propulsive efficiency at high subsonic speeds, while turbofans rely on ducted fans for balance between thrust, noise reduction, and fuel consumption.

Thrust and Performance Comparison

Propfans generate higher thrust at lower speeds due to their open rotor design, which allows for greater bypass ratios and improved fuel efficiency compared to turbofans. Turbofans perform better at higher speeds and altitudes, providing more consistent thrust output and quieter operation with advanced noise-reduction technologies. Performance comparisons show propfans achieve up to 20-30% better fuel efficiency on short to medium-haul flights, while turbofans maintain superior performance and thrust stability during long-haul, high-speed operations.

Fuel Efficiency and Environmental Impact

Propfans achieve higher fuel efficiency than turbofans by combining the speed of jet engines with the fuel economy of propellers, reducing fuel consumption by up to 20-30% on short to medium-haul flights. Their open rotor design enables lower specific fuel consumption, which significantly lowers carbon emissions and contributes to greener aviation. However, increased noise levels from the exposed blades challenge environmental compliance compared to the quieter, enclosed turbofan engines.

Noise Emissions and Mitigation Strategies

Propfans generate higher low-frequency noise due to their open rotor design, posing greater challenges for noise emissions compared to turbofans, which benefit from enclosed fans and advanced acoustic liners. Noise mitigation strategies for propfans include blade sweep optimization, active noise control technologies, and variable pitch mechanisms to reduce blade-vortex interactions and tonal noise. Turbofans leverage chevrons, acoustic liners, and optimized fan blade geometry to minimize high-frequency noise, maintaining quieter cabin environments and compliance with stringent airport noise regulations.

Design Complexity and Maintenance Requirements

Propfan engines feature a more complex blade design with highly swept, unducted fan blades that require precise aerodynamic shaping and advanced materials to manage high tip speeds, resulting in intricate maintenance procedures. Turbofan engines have a simpler, ducted fan design with established maintenance protocols and more accessible inspection points, making upkeep generally less demanding. Maintenance of propfans often involves specialized equipment and expertise due to exposed blades and higher susceptibility to foreign object damage compared to the enclosed turbofan structure.

Cost Analysis: Initial and Lifecycle Costs

Propfan engines typically have lower initial manufacturing costs compared to turbofan engines due to simpler blade designs and materials. Lifecycle costs for propfans are reduced by their superior fuel efficiency, which can decrease operating expenses over time despite potentially higher maintenance requirements. Turbofan engines incur higher initial costs driven by complex technology and material use but benefit from established maintenance infrastructure that can lower long-term repair costs.

Applications in Modern and Future Aircraft

Propfans exhibit superior fuel efficiency at speeds below Mach 0.8, making them ideal for regional and short-haul aircraft seeking reduced operational costs. Turbofans dominate commercial aviation for long-haul flights due to their higher thrust and noise reduction advancements, supporting large airliners like the Boeing 787 and Airbus A350. Emerging hybrid-electric and open-rotor technologies integrate propfan principles, aiming to enhance green aviation initiatives by improving propulsion efficiency and lowering emissions in future aircraft designs.

Technological Advancements and Future Prospects

Propfan engines feature advanced blade designs with swept tips and composite materials, enhancing fuel efficiency and reducing noise compared to traditional turbofans. Turbofan technology continues to improve through high-bypass ratios and geared turbofan systems, offering better thrust-to-weight ratios and lower emissions. Future prospects include hybrid-electric integration and ultra-high bypass propfan variants, targeting significant reductions in carbon footprint and operational costs for commercial aviation.

Bypass Ratio

Propfans typically feature a higher bypass ratio than traditional turbofans, improving fuel efficiency and reducing noise levels significantly.

Open Rotor

Open rotor propfans achieve up to 30% better fuel efficiency than conventional turbofans by combining unshrouded, counter-rotating blades with advanced aerodynamic designs.

Gearbox Integration

Gearbox integration in propfans enhances fuel efficiency by enabling optimal blade speed variation, whereas turbofans typically rely on fixed gear ratios limiting such efficiency gains.

Thrust Specific Fuel Consumption (TSFC)

Propfan engines generally achieve lower Thrust Specific Fuel Consumption (TSFC) than turbofan engines by combining the high speed of turbofans with the fuel efficiency of turboprops through advanced blade designs and improved aerodynamics.

Noise Signature

Propfans generate lower low-frequency noise but higher broadband noise compared to turbofans, resulting in a distinctive noise signature that challenges conventional airport noise regulations.

Blade Sweep

Propfan blades feature a more pronounced blade sweep than turbofan blades, enhancing aerodynamic efficiency and reducing noise at transonic speeds.

Contra-Rotating Propellers

Contra-rotating propfans deliver superior fuel efficiency and thrust compared to traditional turbofans by minimizing axial swirl and enhancing aerodynamic performance through two counter-rotating propeller sets.

Tip Speed

Propfans achieve higher efficiency than turbofans by maintaining lower tip speeds below the transonic regime, reducing shock wave formation and noise.

Ultra-High Bypass Engine (UHBR)

Ultra-High Bypass Ratio (UHBR) turbofan engines offer superior fuel efficiency and lower noise emissions compared to propfans due to their advanced aerodynamic design and higher bypass ratios exceeding 15:1.

Aerodynamic Efficiency

Propfans achieve higher aerodynamic efficiency than turbofans by combining the fuel efficiency of propellers with the high-speed capabilities of jet engines through advanced blade design and reduced drag.

propfan vs turbofan Infographic

njnir.com

njnir.com