Additive manufacturing in aerospace engineering enables the creation of complex geometries with reduced material waste compared to traditional machining, which involves subtracting material from a solid block. This layer-by-layer fabrication technique supports rapid prototyping and customization, significantly shortening production cycles. Traditional machining remains essential for producing high-precision components with established material properties and surface finishes.

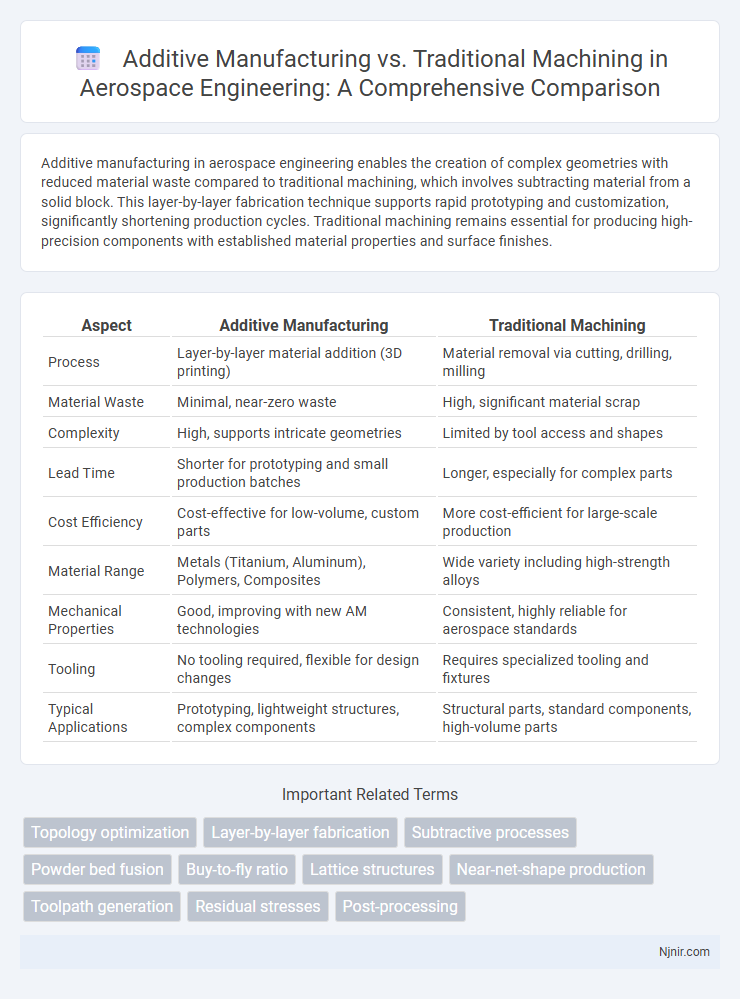

Table of Comparison

| Aspect | Additive Manufacturing | Traditional Machining |

|---|---|---|

| Process | Layer-by-layer material addition (3D printing) | Material removal via cutting, drilling, milling |

| Material Waste | Minimal, near-zero waste | High, significant material scrap |

| Complexity | High, supports intricate geometries | Limited by tool access and shapes |

| Lead Time | Shorter for prototyping and small production batches | Longer, especially for complex parts |

| Cost Efficiency | Cost-effective for low-volume, custom parts | More cost-efficient for large-scale production |

| Material Range | Metals (Titanium, Aluminum), Polymers, Composites | Wide variety including high-strength alloys |

| Mechanical Properties | Good, improving with new AM technologies | Consistent, highly reliable for aerospace standards |

| Tooling | No tooling required, flexible for design changes | Requires specialized tooling and fixtures |

| Typical Applications | Prototyping, lightweight structures, complex components | Structural parts, standard components, high-volume parts |

Introduction to Manufacturing Methods in Aerospace Engineering

Additive manufacturing in aerospace engineering enables the creation of complex, lightweight components layer by layer, optimizing material usage and reducing waste compared to traditional subtractive machining methods. Traditional machining techniques, such as milling and turning, involve removing material from solid blocks, ensuring high precision but often resulting in longer lead times and increased material costs. The integration of additive manufacturing complements conventional processes by enhancing design flexibility and enabling rapid prototyping, crucial for meeting stringent aerospace performance and safety standards.

Fundamentals of Additive Manufacturing

Additive manufacturing builds objects layer by layer using materials such as thermoplastics, metals, and composites, enabling complex geometries that are challenging for traditional machining. This process relies on digital 3D models and advanced technologies like selective laser sintering (SLS) and fused deposition modeling (FDM) to achieve precise material deposition and minimal waste. Unlike subtractive machining, which removes material from a solid block, additive manufacturing promotes design flexibility, efficient resource use, and rapid prototyping in industries including aerospace, automotive, and healthcare.

Overview of Traditional Machining Processes

Traditional machining processes involve subtractive manufacturing techniques such as turning, milling, drilling, and grinding, where material is removed from a solid workpiece using cutting tools. These processes are widely used for producing precise metal parts with tight tolerances in industries like aerospace, automotive, and manufacturing. Traditional machining offers high surface finish quality and material compatibility but often results in longer lead times and higher material waste compared to additive manufacturing.

Material Considerations in Aerospace Components

Additive manufacturing enables the use of complex, lightweight materials such as titanium alloys and high-performance composites, optimizing aerospace components for weight reduction and strength. Traditional machining relies on subtractive processes from bulk materials like aluminum and stainless steel, often resulting in higher material waste and limitations in intricate geometries. Material considerations in aerospace prioritize fatigue resistance, corrosion resistance, and thermal stability, where additive manufacturing offers tailored microstructures and precise control over material properties.

Design Flexibility: Additive vs. Traditional Approaches

Additive manufacturing offers unparalleled design flexibility by enabling the creation of complex geometries, internal structures, and custom features that are difficult or impossible to achieve with traditional machining. Traditional machining relies on subtractive processes, limiting design options to what can be cut, drilled, or milled from solid materials, often resulting in increased material waste. This flexibility in additive manufacturing supports rapid prototyping, lightweight designs, and innovative product development across aerospace, medical, and automotive industries.

Production Speed and Scalability Comparison

Additive manufacturing enables faster prototyping and production by building parts layer-by-layer without tooling constraints, significantly reducing lead times compared to traditional machining. Traditional machining excels in high-volume production with consistent scalability due to well-established processes and equipment optimized for mass manufacturing. Production speed in additive manufacturing varies based on complexity and technology, while traditional machining offers predictable cycle times ideal for large-scale, repetitive tasks.

Cost Analysis: Short-run vs. Mass Production

Additive manufacturing reduces costs in short-run production through minimal setup and material waste, making it ideal for prototypes and customized parts. Traditional machining offers lower unit costs in mass production due to economies of scale and faster production cycles despite higher initial tooling expenses. Cost analysis reveals that additive manufacturing excels in flexibility and cost-efficiency for low volumes, while traditional machining dominates large-scale manufacturing with established processes and optimized resource use.

Surface Finish and Tolerance Achievability

Additive manufacturing often produces rougher surface finishes due to layer-by-layer material deposition, requiring post-processing to meet high-quality standards. Traditional machining excels in achieving fine surface finishes and tighter tolerances because of precise cutting tools and controlled material removal. Tolerance achievability in machining typically reaches micron-level accuracy, whereas additive manufacturing tolerances are generally looser, influenced by machine resolution and material properties.

Environmental Impact and Sustainability Factors

Additive manufacturing significantly reduces material waste by building components layer-by-layer, unlike traditional machining, which often involves subtractive processes generating substantial scrap. Energy consumption in additive manufacturing can be lower due to minimized material removal and shorter production cycles, contributing to reduced carbon footprints. Moreover, additive techniques enable lightweight designs that improve fuel efficiency in aerospace and automotive industries, enhancing overall sustainability.

Future Trends and Integration in Aerospace Manufacturing

Additive manufacturing in aerospace is rapidly evolving with advancements in multi-material printing and real-time adaptive control, enabling complex geometries and weight reduction unattainable by traditional machining. Integration of additive and subtractive methods promotes hybrid manufacturing systems, improving production efficiency and component performance through enhanced precision and material properties. Future trends emphasize digital twins, AI-driven process optimization, and sustainable alloy usage to meet stringent aerospace quality standards and accelerate certification processes.

Topology optimization

Topology optimization in additive manufacturing enables complex, lightweight designs unachievable by traditional machining, significantly enhancing material efficiency and structural performance.

Layer-by-layer fabrication

Additive manufacturing builds complex parts through precise layer-by-layer fabrication, enabling intricate geometries and material efficiency compared to the subtractive process of traditional machining.

Subtractive processes

Additive manufacturing builds objects layer by layer from digital models while traditional subtractive machining removes material from a solid block using cutting tools to achieve the desired shape.

Powder bed fusion

Powder bed fusion additive manufacturing enables intricate geometries and reduced material waste compared to traditional machining, offering enhanced design freedom and faster prototyping.

Buy-to-fly ratio

Additive manufacturing significantly improves the Buy-to-Fly ratio by minimizing material waste compared to traditional machining, where a substantial portion of raw material is removed and discarded.

Lattice structures

Lattice structures in additive manufacturing enable complex geometries with lightweight strength and material efficiency, outperforming traditional machining which struggles to produce intricate internal patterns.

Near-net-shape production

Additive manufacturing enables efficient near-net-shape production by building complex geometries layer-by-layer with minimal material waste, whereas traditional machining relies on subtractive processes that often generate significant scrap and require extensive finishing.

Toolpath generation

Additive manufacturing toolpath generation optimizes layer-by-layer material deposition for complex geometries, whereas traditional machining toolpaths prioritize precise cutting paths to remove material efficiently from solid workpieces.

Residual stresses

Additive manufacturing typically generates lower residual stresses than traditional machining due to its layered material deposition process, reducing the risk of warping and enhancing dimensional accuracy.

Post-processing

Additive manufacturing requires extensive post-processing such as support removal, surface smoothing, and heat treatment, whereas traditional machining typically involves simpler finishing processes like deburring and polishing.

Additive manufacturing vs Traditional machining Infographic

njnir.com

njnir.com