Additive manufacturing in aerospace engineering enables the production of complex, lightweight parts with reduced material waste and shorter lead times compared to subtractive manufacturing. While subtractive methods offer high precision and surface finish for critical components, they often involve significant material removal and longer machining cycles. The integration of additive manufacturing allows for design optimization and rapid prototyping, enhancing overall aerospace part performance and cost-efficiency.

Table of Comparison

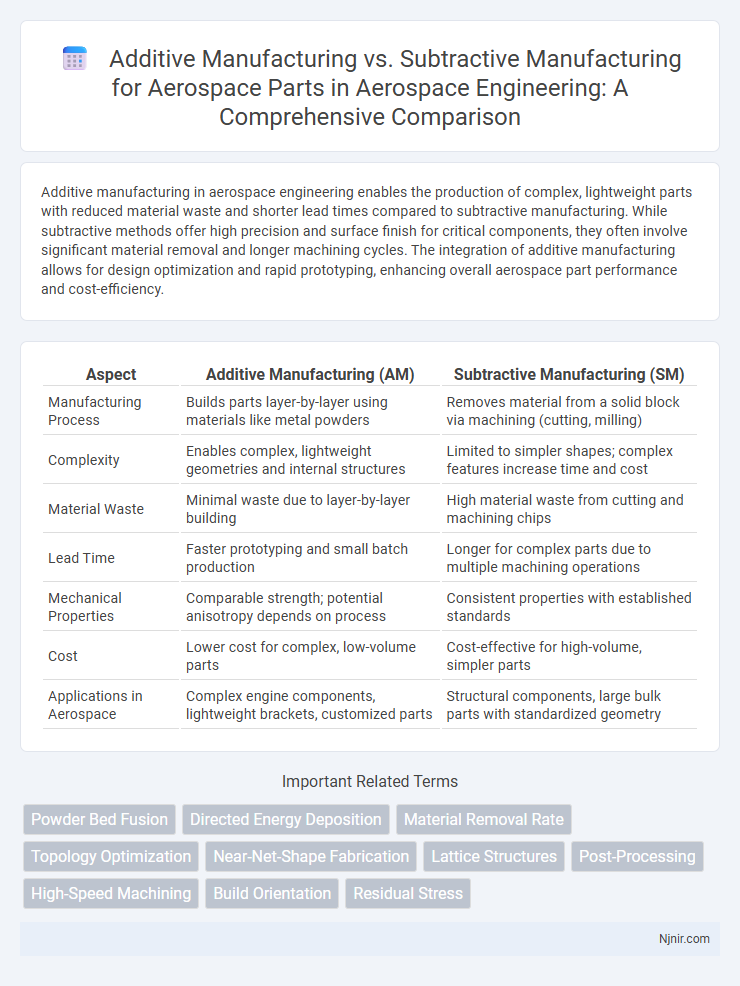

| Aspect | Additive Manufacturing (AM) | Subtractive Manufacturing (SM) |

|---|---|---|

| Manufacturing Process | Builds parts layer-by-layer using materials like metal powders | Removes material from a solid block via machining (cutting, milling) |

| Complexity | Enables complex, lightweight geometries and internal structures | Limited to simpler shapes; complex features increase time and cost |

| Material Waste | Minimal waste due to layer-by-layer building | High material waste from cutting and machining chips |

| Lead Time | Faster prototyping and small batch production | Longer for complex parts due to multiple machining operations |

| Mechanical Properties | Comparable strength; potential anisotropy depends on process | Consistent properties with established standards |

| Cost | Lower cost for complex, low-volume parts | Cost-effective for high-volume, simpler parts |

| Applications in Aerospace | Complex engine components, lightweight brackets, customized parts | Structural components, large bulk parts with standardized geometry |

Introduction to Manufacturing Methods in Aerospace

Additive manufacturing in aerospace enables complex geometries and lightweight designs by layering materials precisely, reducing waste and production time. Subtractive manufacturing, using CNC machining and milling, offers high precision and surface finish by removing material from solid blocks, ideal for critical structural components. Selecting between these methods depends on design complexity, material properties, and aerospace industry standards for safety and performance.

Overview of Additive Manufacturing in Aerospace

Additive manufacturing in aerospace leverages techniques such as selective laser melting and electron beam melting to produce complex, lightweight components with reduced material waste, essential for enhancing fuel efficiency and performance. This layer-by-layer fabrication enables the creation of geometric designs and internal structures impossible to achieve through traditional subtractive methods, allowing for improved thermal properties and strength-to-weight ratios in critical aerospace parts. The adoption of additive manufacturing accelerates prototyping and production cycles while maintaining stringent aerospace quality and certification standards.

Fundamentals of Subtractive Manufacturing for Aerospace Parts

Subtractive manufacturing for aerospace parts involves the process of removing material from a solid block using CNC machining, milling, or turning to achieve precise dimensions and complex geometries. This method offers high accuracy, excellent surface finish, and material integrity, essential for meeting stringent aerospace quality and safety standards. The ability to work with tough metals like titanium and Inconel makes subtractive manufacturing a fundamental technique for producing durable aerospace components.

Material Compatibility: Additive vs Subtractive Processes

Additive manufacturing for aerospace parts offers superior material compatibility by enabling the use of complex alloys and composites that are challenging for subtractive methods due to tool wear and machining constraints. Subtractive manufacturing relies on traditional metals like aluminum and titanium, often limited by material wastage and difficulty in processing high-strength, heat-resistant alloys. Additive processes minimize material waste and support advanced materials like Inconel and carbon fiber composites, crucial for lightweight, high-performance aerospace components.

Design Flexibility and Geometric Complexity

Additive manufacturing in aerospace enables unparalleled design flexibility, allowing complex geometries such as lattice structures and internal channels that are impossible or cost-prohibitive with subtractive methods. Subtractive manufacturing, while precise, often struggles with intricate shapes due to tool accessibility and material waste from cutting processes. The ability of additive techniques to build parts layer-by-layer supports lightweight designs and optimized performance critical for aerospace applications.

Production Speed and Efficiency Comparison

Additive manufacturing enables faster production of complex aerospace parts by building components layer-by-layer directly from digital models, significantly reducing material waste and machining time compared to subtractive methods. Subtractive manufacturing often requires extensive setup and multiple machining steps, leading to longer lead times and increased energy consumption. The efficiency advantage of additive manufacturing is pronounced in low-volume, high-complexity aerospace parts, where speed and material optimization are critical.

Cost Analysis: Additive vs Subtractive Manufacturing

Additive manufacturing reduces material waste by building aerospace parts layer-by-layer, significantly lowering raw material costs compared to subtractive manufacturing, which cuts away excess material. While initial investment for additive equipment can be higher, operational costs decrease due to less tooling and shorter production cycles, making it cost-effective for complex, low-volume parts. Subtractive methods may offer lower unit costs for high-volume, simple geometry parts but incur higher expenses through material waste and extensive machining time.

Surface Finish and Mechanical Properties

Additive manufacturing for aerospace parts offers complex geometries with finer internal structures but often results in rougher surface finishes requiring post-processing, while subtractive manufacturing typically achieves smoother surface finishes directly due to precise machining. Mechanical properties in subtractive manufacturing tend to be more consistent and predictable owing to homogeneous material removal from billets, whereas additive manufacturing parts may exhibit anisotropy and residual stresses from layer-by-layer deposition. Optimizing additive manufacturing processes like laser power and scan speed can improve surface finish and mechanical strength, narrowing the performance gap with subtractive techniques in aerospace applications.

Sustainability and Material Waste Considerations

Additive manufacturing in aerospace significantly reduces material waste by building parts layer-by-layer, using only the necessary amount of raw material, contrasting with subtractive manufacturing which involves removing excess material from larger blocks, leading to substantial scrap. The energy efficiency of additive processes is enhanced through shorter production cycles and reduced tooling requirements, contributing to lower carbon footprints in aerospace component fabrication. Sustainable practices in additive manufacturing also enable the recycling of unused powders, further minimizing environmental impact compared to traditional subtractive methods.

Future Trends and Hybrid Approaches in Aerospace Manufacturing

Additive manufacturing in aerospace enables complex geometries and lightweight structures that traditional subtractive methods struggle to achieve, driving future trends toward integrated hybrid manufacturing systems combining 3D printing and CNC machining. These hybrid approaches optimize material usage, reduce production time, and enhance part performance by leveraging the precision of subtractive machining with the design freedom of additive processes. Advances in multi-material printing and real-time quality control are expected to further transform aerospace manufacturing, enabling the production of functionally graded materials and improved structural integrity.

Powder Bed Fusion

Powder Bed Fusion additive manufacturing enhances aerospace parts production by enabling complex geometries, reduced material waste, and lightweight designs compared to traditional subtractive methods.

Directed Energy Deposition

Directed Energy Deposition (DED) in additive manufacturing enables precise aerospace part fabrication by depositing materials layer-by-layer with focused energy sources, offering superior design flexibility and reduced material waste compared to traditional subtractive manufacturing processes.

Material Removal Rate

Additive manufacturing typically features a lower material removal rate compared to subtractive manufacturing, which efficiently removes large volumes of material for aerospace parts production.

Topology Optimization

Topology optimization enhances additive manufacturing by enabling the design of lightweight, complex aerospace parts with improved structural performance, which is difficult to achieve using subtractive manufacturing techniques.

Near-Net-Shape Fabrication

Near-net-shape fabrication in aerospace parts leverages additive manufacturing for complex geometries and material efficiency, contrasting with subtractive manufacturing's precision by removing excess material from solid blocks.

Lattice Structures

Additive manufacturing enables the production of complex lattice structures for aerospace parts with optimized weight and strength, whereas subtractive manufacturing struggles with such intricate geometries and material efficiency.

Post-Processing

Post-processing of aerospace parts in additive manufacturing typically requires complex surface finishing and heat treatment to achieve required material properties, whereas subtractive manufacturing often involves simpler machining and polishing steps due to the inherently higher initial surface quality.

High-Speed Machining

High-speed machining in subtractive manufacturing provides precise aerospace parts with superior surface finishes and tight tolerances compared to additive manufacturing, which excels in complex geometries but often requires secondary machining for critical components.

Build Orientation

Build orientation in additive manufacturing for aerospace parts optimizes material usage and mechanical properties by enabling complex geometries, whereas subtractive manufacturing's build orientation primarily affects machining accessibility and surface finish quality.

Residual Stress

Additive manufacturing for aerospace parts often results in lower residual stress compared to subtractive manufacturing, improving structural integrity and reducing the risk of fatigue failure.

additive manufacturing vs subtractive manufacturing (for aerospace parts) Infographic

njnir.com

njnir.com