Twisted ducts in aerospace engineering enhance airflow efficiency by reducing turbulence and promoting smoother transitions through curved pathways compared to straight ducts, which may cause increased pressure losses due to abrupt directional changes. The aerodynamic benefits of twisted ducts lead to improved thrust performance and fuel efficiency in aircraft propulsion systems. Material and manufacturing complexities of twisted ducts require advanced fabrication techniques to ensure structural integrity and optimal aerodynamic profiles.

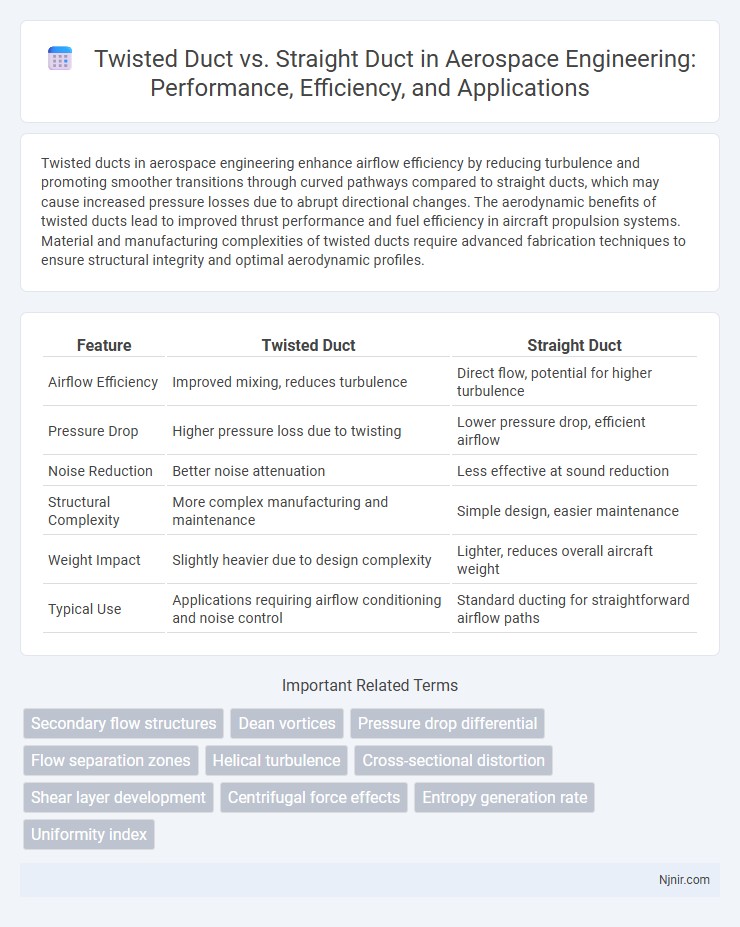

Table of Comparison

| Feature | Twisted Duct | Straight Duct |

|---|---|---|

| Airflow Efficiency | Improved mixing, reduces turbulence | Direct flow, potential for higher turbulence |

| Pressure Drop | Higher pressure loss due to twisting | Lower pressure drop, efficient airflow |

| Noise Reduction | Better noise attenuation | Less effective at sound reduction |

| Structural Complexity | More complex manufacturing and maintenance | Simple design, easier maintenance |

| Weight Impact | Slightly heavier due to design complexity | Lighter, reduces overall aircraft weight |

| Typical Use | Applications requiring airflow conditioning and noise control | Standard ducting for straightforward airflow paths |

Introduction to Duct Design in Aerospace Engineering

Twisted ducts in aerospace engineering enhance airflow control by minimizing aerodynamic losses and improving thrust efficiency compared to straight ducts, which offer simpler construction but may generate higher drag and turbulence. The design of twisted ducts involves complex computational fluid dynamics (CFD) analysis to optimize aerodynamic performance, while straight ducts prioritize manufacturing ease and structural integrity. Effective duct design balances these factors to ensure optimal propulsion system efficiency and aircraft performance.

Fundamentals of Airflow in Ducts

Twisted ducts create turbulence that disrupts streamlined airflow, reducing efficiency and increasing pressure loss compared to straight ducts. Straight ducts maintain laminar airflow, minimizing friction and energy consumption while ensuring consistent air velocity throughout the system. Understanding the impact of duct geometry on airflow dynamics is essential for optimizing HVAC performance and energy efficiency.

Twisted Duct: Definition and Key Characteristics

A twisted duct is a type of air duct that features a helical or spiral shape designed to optimize airflow and reduce turbulence within HVAC systems. Key characteristics include enhanced structural strength, improved pressure distribution, and better sound attenuation compared to straight ducts. This design minimizes air resistance and energy loss, making twisted ducts efficient for ventilation and heating applications in commercial and residential buildings.

Straight Duct: Definition and Core Features

Straight ducts are rigid or flexible air channels designed to transport air efficiently with minimal resistance and turbulence, ensuring optimal airflow in HVAC systems. Core features include a consistent cross-sectional shape, smooth interior surfaces to reduce friction loss, and easy integration with other duct components for streamlined installation. These ducts are essential for maintaining air quality and energy efficiency by facilitating direct and unobstructed air movement.

Aerodynamic Performance Comparison

Twisted ducts improve aerodynamic performance by reducing flow separation and enhancing uniform velocity distribution within the duct, leading to lower pressure losses compared to straight ducts. Straight ducts often experience higher turbulence and increased boundary layer buildup, which results in greater aerodynamic drag and decreased efficiency. Computational fluid dynamics (CFD) studies demonstrate twisted ducts achieve up to 15% better performance in airflow management and energy consumption optimization.

Pressure Drop Analysis: Twisted vs Straight Ducts

Twisted ducts exhibit higher pressure drops compared to straight ducts due to increased airflow turbulence and frictional resistance along the curved surfaces. The spiral geometry in twisted ducts disrupts laminar flow, causing energy losses that result in a measurable pressure differential. In contrast, straight ducts maintain more streamlined airflow, minimizing pressure drop and enhancing system efficiency in HVAC and ventilation applications.

Impact on Flow Uniformity and Turbulence

Twisted ducts enhance flow uniformity by inducing controlled swirl, which promotes better mixing and reduces stagnant zones compared to straight ducts. Straight ducts tend to maintain laminar flow with lower turbulence intensity, potentially causing uneven flow distribution and increased pressure drops. The choice between twisted and straight ducts significantly influences turbulence characteristics, affecting overall system efficiency and aerodynamic performance.

Structural and Manufacturing Considerations

Twisted ducts require complex manufacturing processes involving precise twisting and forming techniques to maintain integrity, often increasing production time and costs compared to straight ducts. Structurally, twisted ducts exhibit enhanced flexibility and aerodynamic efficiency in airflow management but may experience increased stress concentrations that necessitate reinforced materials or thicker walls. Straight ducts offer simpler fabrication with consistent cross-sectional geometry, resulting in robust structural stability and easier installation but can lack the aerodynamic benefits of twisted designs.

Application Scenarios in Aircraft Systems

Twisted ducts in aircraft systems are often used where airflow direction needs to change smoothly within confined spaces, such as in wing leading-edge cooling or complex engine nacelle ventilation, improving aerodynamic efficiency and reducing turbulence. Straight ducts are typically preferred for primary air distribution in fuselage environmental control systems and long, linear pathways where minimal pressure drop and straightforward installation are priorities. Each duct type optimizes system performance by balancing airflow dynamics and structural constraints within specific aircraft applications.

Summary and Future Trends

Twisted ducts improve airflow efficiency by reducing turbulence compared to straight ducts, enhancing HVAC system performance and energy savings. Emerging trends focus on integrating smart sensors and adaptive materials to optimize air distribution dynamically within twisted duct designs. Future developments aim to combine aerodynamic innovation with IoT technology to create responsive, energy-efficient ventilation systems.

Secondary flow structures

Twisted ducts generate stronger secondary flow structures that enhance mixing and heat transfer efficiency compared to straight ducts with weaker secondary flow patterns.

Dean vortices

Twisted ducts enhance heat transfer efficiency by inducing stronger Dean vortices that improve fluid mixing compared to straight ducts with weaker vortex formation.

Pressure drop differential

Twisted ducts generate higher pressure drop compared to straight ducts due to increased turbulence and flow resistance within the twisted geometry.

Flow separation zones

Twisted ducts reduce flow separation zones compared to straight ducts by promoting smoother airflow and minimizing turbulence.

Helical turbulence

Helical turbulence in twisted ducts enhances mixing efficiency and heat transfer rates compared to laminar flow in straight ducts by inducing centrifugal forces that disrupt boundary layers.

Cross-sectional distortion

Twisted ducts exhibit significantly greater cross-sectional distortion compared to straight ducts, resulting in increased airflow resistance and reduced aerodynamic efficiency.

Shear layer development

Twisted ducts enhance shear layer development by promoting stronger turbulence and mixing compared to straight ducts, resulting in improved flow homogeneity and heat transfer efficiency.

Centrifugal force effects

Twisted ducts generate complex centrifugal forces causing uneven airflow and pressure losses, while straight ducts maintain more uniform centrifugal forces, resulting in smoother airflow and higher efficiency.

Entropy generation rate

Twisted ducts significantly increase entropy generation rates compared to straight ducts due to enhanced flow turbulence and mixing, which improves heat transfer efficiency but leads to higher thermodynamic irreversibility.

Uniformity index

Twisted ducts significantly improve the uniformity index compared to straight ducts by enhancing airflow distribution and reducing velocity gradients.

Twisted duct vs Straight duct Infographic

njnir.com

njnir.com