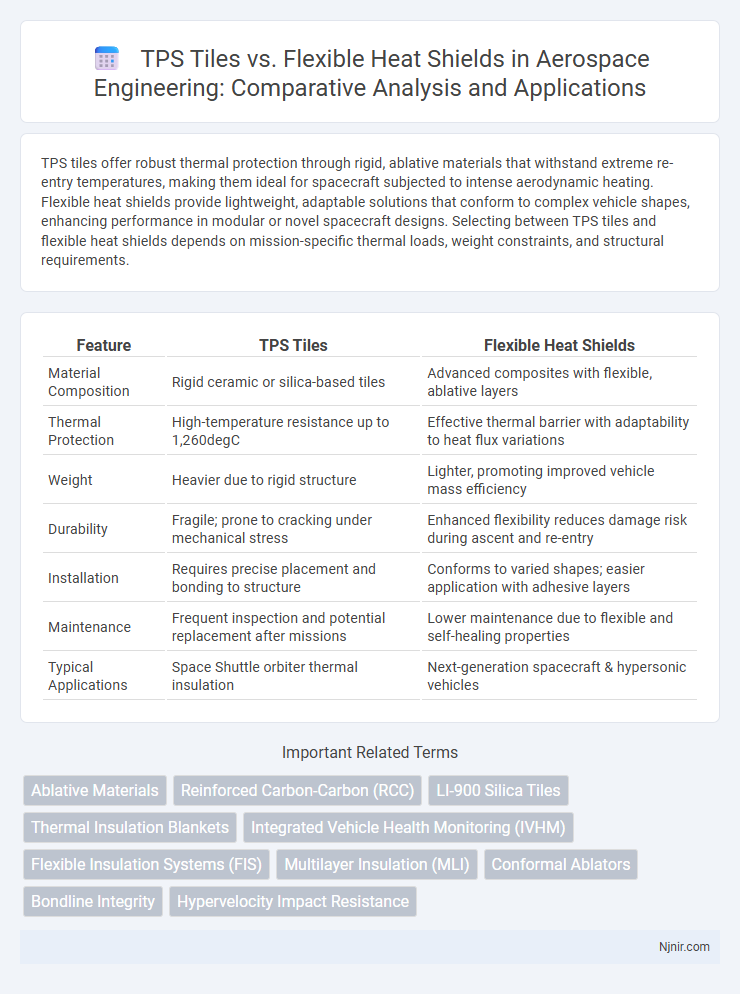

TPS tiles offer robust thermal protection through rigid, ablative materials that withstand extreme re-entry temperatures, making them ideal for spacecraft subjected to intense aerodynamic heating. Flexible heat shields provide lightweight, adaptable solutions that conform to complex vehicle shapes, enhancing performance in modular or novel spacecraft designs. Selecting between TPS tiles and flexible heat shields depends on mission-specific thermal loads, weight constraints, and structural requirements.

Table of Comparison

| Feature | TPS Tiles | Flexible Heat Shields |

|---|---|---|

| Material Composition | Rigid ceramic or silica-based tiles | Advanced composites with flexible, ablative layers |

| Thermal Protection | High-temperature resistance up to 1,260degC | Effective thermal barrier with adaptability to heat flux variations |

| Weight | Heavier due to rigid structure | Lighter, promoting improved vehicle mass efficiency |

| Durability | Fragile; prone to cracking under mechanical stress | Enhanced flexibility reduces damage risk during ascent and re-entry |

| Installation | Requires precise placement and bonding to structure | Conforms to varied shapes; easier application with adhesive layers |

| Maintenance | Frequent inspection and potential replacement after missions | Lower maintenance due to flexible and self-healing properties |

| Typical Applications | Space Shuttle orbiter thermal insulation | Next-generation spacecraft & hypersonic vehicles |

Introduction to TPS Tiles and Flexible Heat Shields

TPS tiles are advanced thermal protection materials used primarily on spacecraft like the Space Shuttle to withstand extreme re-entry temperatures by insulating the vehicle's structure. Flexible heat shields consist of lightweight, adaptable materials designed for reusable spacecraft and other aerodynamic vehicles, providing thermal protection through layers of insulating fabrics and reflective coatings. Both systems aim to manage heat loads during atmospheric entry but differ significantly in their form factor, weight, and application methods.

Historical Development of Thermal Protection Systems

Thermal Protection Systems (TPS) have evolved from rigid TPS tiles used in early spacecraft like the Space Shuttle, known for their high- temperature resistance but brittleness and weight constraints. Flexible heat shields emerged as a significant innovation, offering lightweight, adaptable thermal barriers made from advanced materials such as silica fabrics and ceramic composites. This evolution reflects a shift towards more efficient thermal protection in modern aerospace technologies, improving durability and reducing overall mission costs.

Material Composition: Tiles vs Flexible Shields

TPS tiles are typically made of rigid ceramic materials such as silica or carbon-based composites designed to withstand extreme temperatures and thermal shock during spacecraft reentry. Flexible heat shields, on the other hand, utilize advanced woven or layered materials like flexible carbon fabrics, polyimide films, or ablative composites, allowing them to conform to complex shapes while providing effective thermal protection. The key difference lies in the rigidity and structural composition, with TPS tiles offering high-temperature resistance through ceramics and flexible shields relying on pliable, heat-resistant fibers and resins for adaptability and durability.

Thermal Performance and Effectiveness

TPS tiles offer superior thermal performance due to their high heat resistance and low thermal conductivity, effectively insulating spacecraft surfaces from extreme temperatures during reentry. Flexible heat shields provide adaptable coverage with lightweight materials designed for rapid deployment, though they generally exhibit lower thermal resistance compared to rigid TPS tiles. The effectiveness of TPS tiles in protecting structural integrity at temperatures exceeding 1500degC typically surpasses that of flexible heat shields, which perform best in moderate thermal environments.

Structural Integration with Spacecraft

TPS tiles offer exceptional thermal protection due to their rigid structure, enabling precise integration with spacecraft surfaces and maintaining structural integrity during re-entry. Flexible heat shields provide adaptability to complex geometries, allowing seamless coverage over curved or moving spacecraft components while reducing weight and minimizing stress concentrations. Effective structural integration of either system depends on material compatibility and attachment methods ensuring durability under extreme thermal and mechanical loads.

Manufacturing Processes and Costs

TPS tiles, made using high-performance ceramic composites through precision molding and sintering, require intricate manufacturing processes that drive up production costs. Flexible heat shields utilize lightweight, multi-layered insulation materials fabricated via lamination and layering techniques, enabling faster production and lower expenses. The complex curing and quality control needed for TPS tiles result in significantly higher costs compared to the scalable, cost-effective manufacturing of flexible heat shields.

Damage Tolerance and Maintenance Requirements

TPS tiles offer high damage tolerance with excellent thermal protection and can withstand repeated thermal cycling but are susceptible to impact damage and require careful inspection and repair. Flexible heat shields provide moderate damage tolerance with better resistance to mechanical stresses and easier handling but may lack the same high-temperature durability as rigid tiles. Maintenance requirements for TPS tiles involve meticulous tile inspection and replacement, while flexible heat shields allow quicker repairs due to their pliable materials and modular installation.

Applications in Modern Aerospace Missions

TPS tiles provide essential thermal protection for spacecraft re-entering Earth's atmosphere, with high resistance to extreme temperatures and ablation, making them ideal for reusable spacecraft like the Space Shuttle. Flexible heat shields, composed of advanced woven materials and insulative layers, offer lightweight and conformable solutions suited for irregular shapes and dynamic mission profiles, such as those on Mars landers and small satellites. Modern aerospace missions leverage TPS tiles for durable, high-temperature endurance while employing flexible heat shields to optimize mass and adaptability in complex thermal environments.

Advantages and Limitations of Each System

Thermal Protection System (TPS) tiles offer superior heat resistance and durability, making them ideal for high-temperature reentry environments due to their ability to withstand thermal shock and provide insulation; however, they are brittle, prone to damage, and require high maintenance. Flexible heat shields provide lightweight, conformable solutions with easier installation and repair processes, enhancing spacecraft agility and performance, but they typically offer lower thermal protection and reduced lifespan under extreme reentry conditions. Selecting between TPS tiles and flexible heat shields depends on mission-specific thermal loads, structural requirements, and maintenance capabilities for optimal spacecraft protection.

Future Trends in Thermal Protection Technologies

TPS tiles are advancing with enhanced ceramic matrix composites offering superior thermal resistance and durability for hypersonic applications, while flexible heat shields are evolving using ultra-lightweight ablative materials and adaptive layers to improve deployability and thermal management on irregular surfaces. Innovations in nanomaterials and phase-change substances are driving the development of hybrid systems that combine the rigidity of TPS with the conformability of flexible shields, optimizing thermal protection for next-generation spacecraft and reentry vehicles. Future trends emphasize modular, repairable designs integrated with real-time thermal sensors to enable autonomous heat flux monitoring and adaptive response during atmospheric reentry.

Ablative Materials

TPS tiles use ablative materials that sacrificially erode to absorb and dissipate intense heat, whereas flexible heat shields rely on layered composites that resist heat through insulation without material erosion.

Reinforced Carbon-Carbon (RCC)

Reinforced Carbon-Carbon (RCC) offers superior thermal protection and structural strength compared to TPS tiles and flexible heat shields, making it essential for high-temperature aerospace applications.

LI-900 Silica Tiles

LI-900 silica tiles, used in TPS systems, offer superior thermal insulation and durability compared to flexible heat shields, making them essential for high-temperature aerospace applications.

Thermal Insulation Blankets

Thermal insulation blankets made from TPS tiles offer superior heat resistance and durability compared to flexible heat shields, providing enhanced protection in high-temperature environments.

Integrated Vehicle Health Monitoring (IVHM)

TPS tiles provide localized thermal protection with limited sensor integration, whereas flexible heat shields enhance Integrated Vehicle Health Monitoring (IVHM) by enabling distributed temperature sensing and real-time damage detection across vehicle surfaces.

Flexible Insulation Systems (FIS)

Flexible Insulation Systems (FIS) provide superior thermal protection and adaptability compared to TPS tiles by offering enhanced conformability, reduced weight, and improved durability for aerospace applications.

Multilayer Insulation (MLI)

TPS tiles provide robust thermal protection through rigid Multilayer Insulation (MLI) layers that withstand extreme reentry heat, while flexible heat shields utilize adaptable MLI materials offering enhanced conformability and weight savings for versatile spacecraft thermal management.

Conformal Ablators

Conformal ablators provide superior heat resistance and uniform protection compared to traditional TPS tiles and flexible heat shields by closely matching spacecraft contours and efficiently managing thermal loads during atmospheric reentry.

Bondline Integrity

TPS tiles maintain superior bondline integrity compared to flexible heat shields due to their rigid structure and advanced adhesive formulations that resist thermal cycling and mechanical stress.

Hypervelocity Impact Resistance

TPS tiles provide superior hypervelocity impact resistance compared to flexible heat shields due to their rigid ceramic composition and ablative properties.

TPS Tiles vs Flexible Heat Shields Infographic

njnir.com

njnir.com