Boundary layer ingestion (BLI) enhances propulsion efficiency by capturing and accelerating slower-moving air near the aircraft surface, reducing drag and fuel consumption compared to conventional inlets. Unlike traditional inlets positioned ahead of the wing, BLI integrates the engine closer to the airframe, improving overall aerodynamic performance. This innovative approach contributes to noise reduction and lower emissions, making it a promising technology for future aerospace propulsion systems.

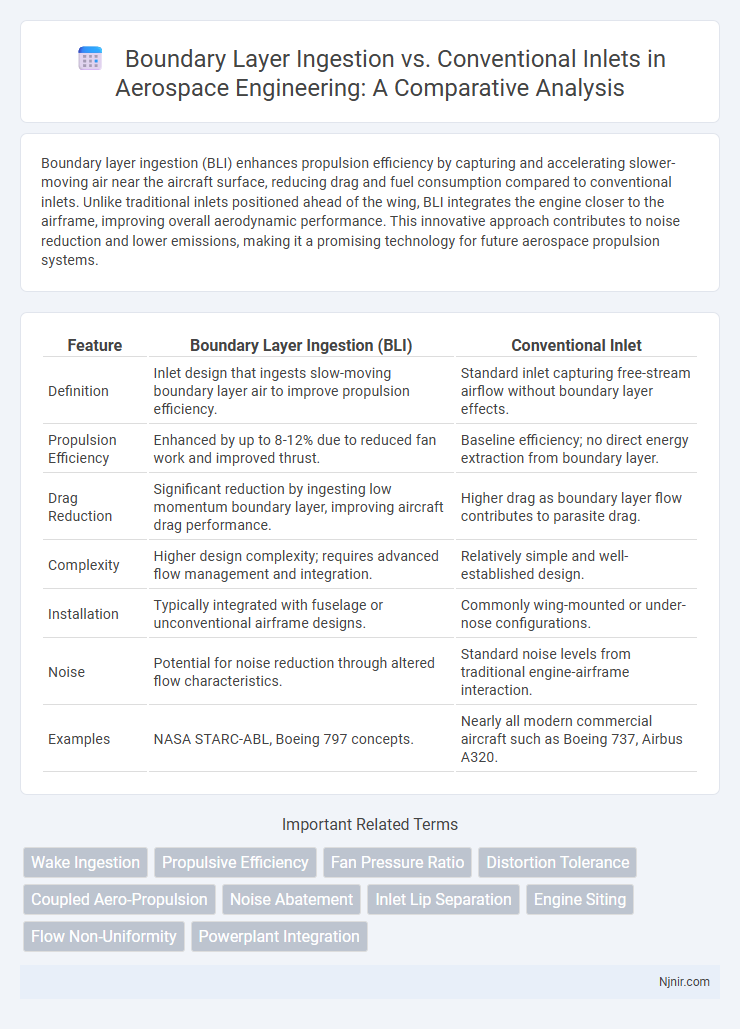

Table of Comparison

| Feature | Boundary Layer Ingestion (BLI) | Conventional Inlet |

|---|---|---|

| Definition | Inlet design that ingests slow-moving boundary layer air to improve propulsion efficiency. | Standard inlet capturing free-stream airflow without boundary layer effects. |

| Propulsion Efficiency | Enhanced by up to 8-12% due to reduced fan work and improved thrust. | Baseline efficiency; no direct energy extraction from boundary layer. |

| Drag Reduction | Significant reduction by ingesting low momentum boundary layer, improving aircraft drag performance. | Higher drag as boundary layer flow contributes to parasite drag. |

| Complexity | Higher design complexity; requires advanced flow management and integration. | Relatively simple and well-established design. |

| Installation | Typically integrated with fuselage or unconventional airframe designs. | Commonly wing-mounted or under-nose configurations. |

| Noise | Potential for noise reduction through altered flow characteristics. | Standard noise levels from traditional engine-airframe interaction. |

| Examples | NASA STARC-ABL, Boeing 797 concepts. | Nearly all modern commercial aircraft such as Boeing 737, Airbus A320. |

Introduction to Boundary Layer Ingestion and Conventional Inlets

Boundary layer ingestion (BLI) integrates the aircraft's propulsion system with its aerodynamic surface by ingesting slower-moving air close to the fuselage, improving propulsive efficiency compared to conventional inlets. Conventional inlets typically capture freestream air, resulting in standard pressure recovery but higher drag due to separated boundary layers around the aircraft body. BLI technology reduces total drag and enhances fuel efficiency by re-energizing the boundary layer, presenting a promising advancement in aircraft propulsion design.

Fundamental Principles of Boundary Layer Ingestion

Boundary layer ingestion (BLI) enhances propulsion efficiency by capturing low-momentum airflow within the aircraft's boundary layer, reducing the overall drag and increasing propulsive thrust. Unlike conventional inlets that ingest high-velocity free-stream air, BLI utilizes slower-moving, boundary layer flow, requiring specialized engine and inlet designs to manage distorted airflow and maintain stable thrust. Fundamental principles of BLI emphasize optimizing inlet geometry and engine integration to recover wake energy, improve fuel efficiency, and reduce emissions.

Conventional Inlet Design and Operation

Conventional inlet design typically features a clean, undisturbed airflow path that minimizes total pressure losses, optimizing engine performance under various flight conditions. These inlets maintain smooth external surfaces to reduce boundary layer thickness and avoid flow separation, ensuring stable and efficient airflow into the engine compressor. Operation relies heavily on precise inlet geometry and shock management techniques, particularly in supersonic regimes, to maximize pressure recovery and prevent inlet buzz or surge.

Aerodynamic Efficiency: BLI vs. Conventional Inlets

Boundary layer ingestion (BLI) improves aerodynamic efficiency by reducing wake drag and utilizing slower-moving boundary layer air, which decreases overall propulsion system energy losses compared to conventional inlets ingesting faster, free-stream flow. BLI enables higher propulsive efficiency by allowing the engine to recover energy from the aircraft's boundary layer, leading to potential fuel savings of 8-10%. Unlike conventional inlets that disrupt smooth airflow and generate additional drag, BLI enhances aerodynamic integration and optimization in modern aircraft designs.

Impact on Fuel Consumption and Emissions

Boundary layer ingestion (BLI) reduces aerodynamic drag by ingesting slower-moving airflow from near the aircraft surface, leading to lower engine power requirements and significant reductions in fuel consumption compared to conventional inlets. Studies indicate that BLI can improve fuel efficiency by up to 8-15%, translating into proportional decreases in CO2 and NOx emissions. The integration of BLI in aircraft propulsion systems enhances overall environmental performance by minimizing fuel burn and emissions during cruise conditions.

Structural and Integration Challenges

Boundary layer ingestion (BLI) reduces aerodynamic drag by ingesting slower-moving air along the aircraft surface, but presents significant structural challenges due to uneven pressure distribution and increased vibrational loads on engine components. Integration complexity arises from the need to position engines closer to the fuselage or wing surface, requiring reinforced airframe structures to accommodate altered load paths and maintain aerodynamic efficiency. Conventional inlets, positioned away from the boundary layer, typically experience more uniform airflow, simplifying structural design and integration but sacrificing potential efficiency gains from BLI.

Noise and Acoustic Considerations

Boundary layer ingestion (BLI) significantly reduces engine inlet noise by ingesting slower-moving, turbulent boundary layer air, which lowers fan noise generation compared to conventional inlets ingesting freestream flow. The altered flow characteristics in BLI can modify acoustic impedance, requiring specialized nacelle design to mitigate tonal noise and broadband acoustic emissions effectively. Studies indicate BLI configurations can achieve up to 3-6 dB reductions in perceived noise levels, crucial for compliance with stringent airport noise regulations.

Propulsion System Performance Comparisons

Boundary layer ingestion (BLI) improves propulsion system performance by recovering slower-moving air near the aircraft surface, reducing inlet distortion and increasing propulsive efficiency compared to conventional inlets. BLI enables lower total pressure losses and a higher effective bypass ratio, resulting in significant fuel consumption reductions. Conventional inlets experience greater aerodynamic losses and less integration with the airframe, leading to decreased overall propulsion efficiency.

Technological Advancements Enabling BLI

Technological advancements enabling boundary layer ingestion (BLI) focus on advanced aerodynamic designs and computational fluid dynamics (CFD) that optimize airflow and reduce drag by ingesting slower boundary layer air from the aircraft surface. Innovations in propulsion integration, such as distributed electric propulsion and embedded engines, enhance efficiency and propulsion-airframe synergy compared to conventional inlets. Adaptive materials and active flow control technologies further enable precise boundary layer manipulation, improving BLI system performance and operational robustness.

Future Prospects and Applications in Aerospace Engineering

Boundary layer ingestion (BLI) technology offers significant improvements in fuel efficiency and reduction of aircraft emissions compared to conventional inlets by integrating propulsion systems directly into the aircraft's surface. Future prospects in aerospace engineering include advanced hybrid-electric propulsion systems and urban air mobility vehicles, leveraging BLI to maximize aerodynamic benefits and minimize energy consumption. Application of BLI in next-generation commercial and regional aircraft aims to achieve sustainable aviation goals through optimized airflow management and integrated propulsion design.

Wake Ingestion

Wake ingestion in boundary layer ingestion (BLI) systems enhances propulsion efficiency by reducing inlet total pressure losses compared to conventional inlets operating in free-stream airflow.

Propulsive Efficiency

Boundary layer ingestion enhances propulsive efficiency by reducing inlet losses and leveraging slower-moving air near the aircraft surface, unlike conventional inlets that ingest higher-energy freestream air resulting in greater drag and lower overall propulsion performance.

Fan Pressure Ratio

Boundary layer ingestion reduces fan pressure ratio requirements by utilizing slower-moving airflow from the aircraft's boundary layer, enhancing propulsion efficiency compared to conventional inlets that ingest higher-velocity free stream air.

Distortion Tolerance

Boundary layer ingestion engines exhibit improved distortion tolerance compared to conventional inlets by effectively managing non-uniform airflow and reducing inlet distortion for enhanced propulsion efficiency.

Coupled Aero-Propulsion

Boundary layer ingestion in coupled aero-propulsion systems enhances propulsive efficiency by ingesting slower-moving boundary layer air, reducing total aircraft drag compared to conventional inlets.

Noise Abatement

Boundary layer ingestion (BLI) reduces aircraft noise levels by decreasing inlet turbulence and engine noise compared to conventional inlets, enhancing overall noise abatement effectiveness.

Inlet Lip Separation

Boundary layer ingestion significantly reduces inlet lip separation compared to conventional inlets by effectively managing slower airflow near the aircraft surface and maintaining smoother flow attachment.

Engine Siting

Boundary layer ingestion engine siting improves aircraft propulsion efficiency by positioning the engine to ingest slower-moving boundary layer airflow, reducing total drag compared to conventional inlet placement at the freestream airflow.

Flow Non-Uniformity

Boundary layer ingestion inlets significantly reduce flow non-uniformity by capturing slower-moving boundary layer air, enhancing propulsion efficiency compared to conventional inlets that ingest uniform free-stream flow.

Powerplant Integration

Boundary layer ingestion enhances powerplant integration by reducing inlet distortion and drag, improving propulsion efficiency compared to conventional inlets.

boundary layer ingestion vs conventional inlet Infographic

njnir.com

njnir.com