Blended Wing Body (BWB) aircraft designs integrate the wings and fuselage into a single seamless structure, offering superior aerodynamic efficiency and reduced fuel consumption compared to traditional Tube-and-Wing configurations. This integration enhances lift-to-drag ratios and improves structural weight distribution, leading to increased payload capacity and range. Despite manufacturing complexities, BWB designs promise significant advancements in noise reduction and environmental sustainability for next-generation aerospace engineering.

Table of Comparison

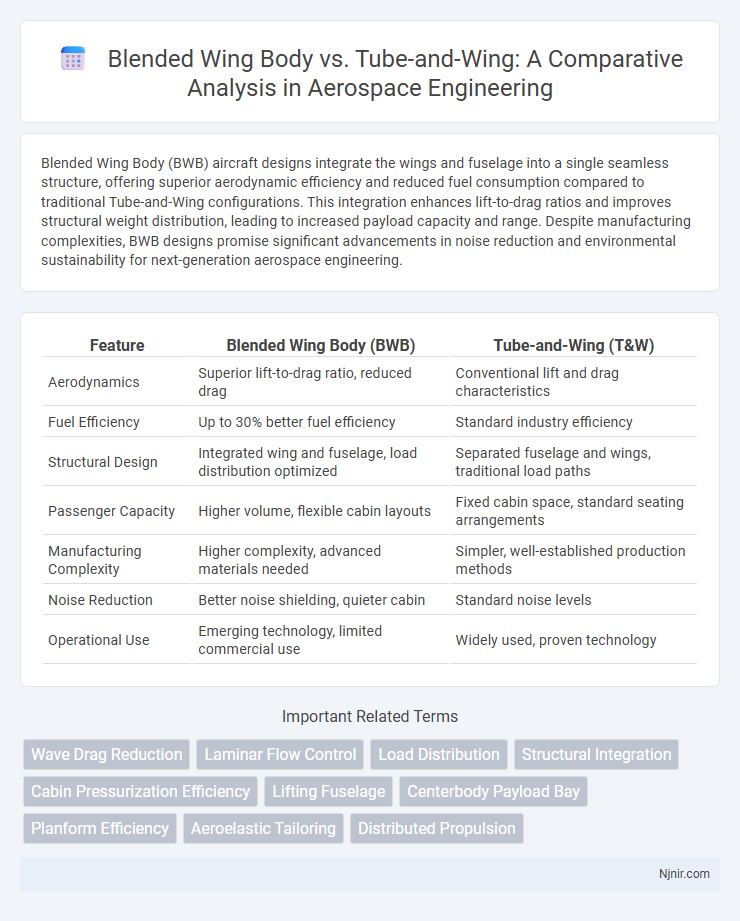

| Feature | Blended Wing Body (BWB) | Tube-and-Wing (T&W) |

|---|---|---|

| Aerodynamics | Superior lift-to-drag ratio, reduced drag | Conventional lift and drag characteristics |

| Fuel Efficiency | Up to 30% better fuel efficiency | Standard industry efficiency |

| Structural Design | Integrated wing and fuselage, load distribution optimized | Separated fuselage and wings, traditional load paths |

| Passenger Capacity | Higher volume, flexible cabin layouts | Fixed cabin space, standard seating arrangements |

| Manufacturing Complexity | Higher complexity, advanced materials needed | Simpler, well-established production methods |

| Noise Reduction | Better noise shielding, quieter cabin | Standard noise levels |

| Operational Use | Emerging technology, limited commercial use | Widely used, proven technology |

Introduction to Aerospace Aircraft Configurations

Blended Wing Body (BWB) aircraft feature an integrated wing and fuselage design that enhances aerodynamic efficiency and reduces drag compared to traditional Tube-and-Wing configurations. The Tube-and-Wing layout, characterized by a cylindrical fuselage attached to distinct wings, remains the dominant design due to its structural simplicity and established manufacturing processes. Advances in aerospace engineering increasingly favor BWB concepts for their potential to improve fuel efficiency and payload capacity in future commercial and military aircraft.

Blended Wing Body: Design Principles

Blended Wing Body (BWB) aircraft integrate the fuselage and wings into a single lifting surface, reducing aerodynamic drag and improving fuel efficiency compared to traditional tube-and-wing designs. The design principles emphasize a wide, spacious interior and structural efficiency by distributing loads more evenly across the airframe, enhancing payload capacity. Advanced materials and computational fluid dynamics (CFD) are utilized to optimize the smooth, continuous shape, minimizing turbulence and maximizing lift-to-drag ratio.

Tube-and-Wing: Traditional Design Overview

Tube-and-wing aircraft feature a cylindrical fuselage paired with distinct wing structures, optimizing passenger cabin space and structural efficiency. This traditional design has dominated commercial aviation due to its proven aerodynamic stability and ease of manufacturing. Engineers favor the tube-and-wing layout for its ability to support heavy payloads while maintaining effective lift-to-drag ratios across diverse flight conditions.

Aerodynamic Efficiency: BWB vs Tube-and-Wing

The Blended Wing Body (BWB) design offers superior aerodynamic efficiency compared to traditional tube-and-wing configurations by reducing drag through its smooth, continuous fuselage-wing integration. This design minimizes wetted area and improves lift-to-drag ratio, resulting in enhanced fuel efficiency and lower emissions. Advanced computational fluid dynamics simulations demonstrate that BWBs can achieve up to 20-30% better aerodynamic performance, crucial for next-generation sustainable aviation.

Structural Considerations and Weight

Blended Wing Body (BWB) aircraft exhibit a structurally efficient design by integrating the wing and fuselage into a single lifting surface, reducing the number of structural components and distributing aerodynamic loads more evenly, which significantly lowers the overall airframe weight. In contrast, traditional Tube-and-Wing configurations require heavier fuselage frameworks and wing-to-fuselage joints that introduce stress concentrations and increase structural mass. Consequently, BWB designs offer substantial weight savings and improved fuel efficiency due to optimized load paths and reduced use of reinforcement materials.

Fuel Efficiency and Environmental Impact

Blended Wing Body (BWB) aircraft demonstrate superior fuel efficiency compared to traditional Tube-and-Wing designs by reducing aerodynamic drag through their integrated fuselage and wing structure, resulting in up to 20-30% lower fuel consumption. This improved efficiency directly lowers greenhouse gas emissions, contributing to a significant reduction in the aviation industry's carbon footprint. Airlines adopting BWB technology can achieve substantial environmental benefits, aligning with global sustainability goals and regulatory pressures to minimize aviation-related pollution.

Passenger Comfort and Cabin Layout

Blended Wing Body (BWB) aircraft offer enhanced passenger comfort through wider, open cabin layouts that increase spatial perception and enable more flexible seating arrangements compared to traditional tube-and-wing designs. The BWB structure distributes pressure more evenly, reducing noise and vibration levels and providing a quieter, smoother flight experience. In contrast, tube-and-wing cabins typically feature narrower fuselages with constrained aisle widths, limiting passenger movement and reducing overall comfort during longer flights.

Manufacturing Challenges and Costs

Blended Wing Body (BWB) aircraft present significant manufacturing challenges due to their complex, non-linear airframe structures requiring advanced composites and innovative tooling, leading to higher initial production costs compared to traditional tube-and-wing designs. The tube-and-wing configuration benefits from decades of standardized manufacturing processes and established supply chains that reduce labor and material expenses, promoting cost efficiency in assembly and maintenance. Despite the higher upfront investment, BWB designs promise long-term operational savings through improved aerodynamics and fuel efficiency, which could offset manufacturing expenditures as production technologies mature.

Operational Adaptability and Airport Compatibility

Blended Wing Body (BWB) designs offer superior operational adaptability through enhanced fuel efficiency and greater payload capacity compared to conventional tube-and-wing aircraft, enabling longer ranges and varied mission profiles. BWB's wider, flatter fuselage challenges existing airport compatibility due to gate size limitations and taxiway width, whereas tube-and-wing configurations conform to standardized airport infrastructure, ensuring smoother integration. Airlines must balance BWB's performance benefits against potential costly ground facility modifications when considering fleet modernization.

Future Prospects and Industry Adoption

Blended Wing Body (BWB) aircraft offer significant fuel efficiency and reduced emissions compared to traditional Tube-and-Wing designs, making them attractive for the aviation industry's shift toward sustainability. Industry leaders and research organizations are investing heavily in BWB technology for next-generation commercial and cargo aircraft, aiming to meet stringent environmental regulations and lower operational costs. While Tube-and-Wing remains dominant due to proven reliability and existing infrastructure, growing environmental concerns and advancements in materials and aerodynamics are accelerating BWB adoption prospects in the mid to long term.

Wave Drag Reduction

Blended Wing Body aircraft reduce wave drag by integrating lift-generating surfaces with smooth, continuous fuselage contours, achieving up to 30% lower wave drag compared to traditional Tube-and-Wing designs.

Laminar Flow Control

Blended Wing Body aircraft exhibit enhanced laminar flow control compared to traditional Tube-and-Wing designs, resulting in significantly reduced aerodynamic drag and increased fuel efficiency.

Load Distribution

Blended Wing Body designs achieve superior load distribution by integrating wing and fuselage structures, reducing stress concentrations compared to traditional Tube-and-Wing configurations.

Structural Integration

Blended Wing Body aircraft demonstrate superior structural integration by combining the fuselage and wing into a single load-bearing structure, resulting in enhanced aerodynamic efficiency and weight reduction compared to the traditional Tube-and-Wing design with separate fuselage and wings.

Cabin Pressurization Efficiency

Blended Wing Body aircraft achieve higher cabin pressurization efficiency than Tube-and-Wing designs due to their larger internal volume and lower structural stress, enabling lower differential pressure requirements and enhanced passenger comfort.

Lifting Fuselage

The Blended Wing Body design enhances aerodynamic efficiency by integrating the lifting fuselage to generate additional lift, unlike the conventional Tube-and-Wing aircraft where the fuselage primarily serves as payload space without significant lift contribution.

Centerbody Payload Bay

The Blended Wing Body design features a larger, more integrated centerbody payload bay that enables greater volumetric efficiency and payload capacity compared to the traditional Tube-and-Wing layout's separate fuselage bay.

Planform Efficiency

The Blended Wing Body design achieves superior planform efficiency compared to the traditional Tube-and-Wing configuration by minimizing aerodynamic drag and maximizing lift distribution across a seamless, integrated airframe.

Aeroelastic Tailoring

Blended Wing Body aircraft enhance aeroelastic tailoring by optimizing wing flexibility and load distribution to reduce structural weight and improve fuel efficiency compared to conventional Tube-and-Wing designs.

Distributed Propulsion

Distributed propulsion in Blended Wing Body designs enhances aerodynamic efficiency and reduces fuel consumption compared to conventional Tube-and-Wing aircraft by integrating multiple smaller engines across the airframe surface.

Blended Wing Body vs Tube-and-Wing Infographic

njnir.com

njnir.com