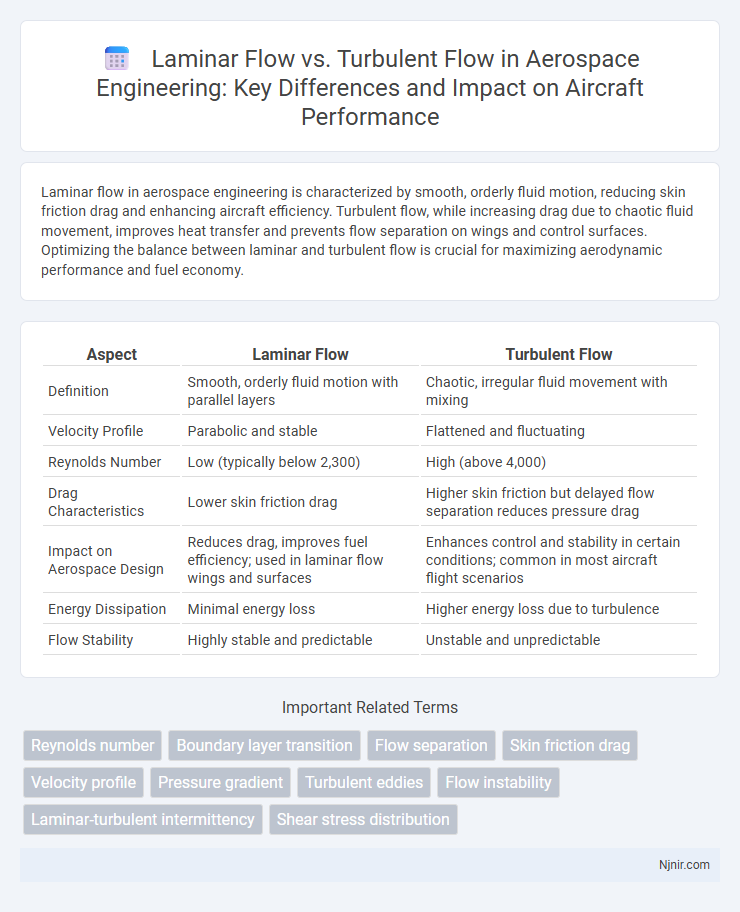

Laminar flow in aerospace engineering is characterized by smooth, orderly fluid motion, reducing skin friction drag and enhancing aircraft efficiency. Turbulent flow, while increasing drag due to chaotic fluid movement, improves heat transfer and prevents flow separation on wings and control surfaces. Optimizing the balance between laminar and turbulent flow is crucial for maximizing aerodynamic performance and fuel economy.

Table of Comparison

| Aspect | Laminar Flow | Turbulent Flow |

|---|---|---|

| Definition | Smooth, orderly fluid motion with parallel layers | Chaotic, irregular fluid movement with mixing |

| Velocity Profile | Parabolic and stable | Flattened and fluctuating |

| Reynolds Number | Low (typically below 2,300) | High (above 4,000) |

| Drag Characteristics | Lower skin friction drag | Higher skin friction but delayed flow separation reduces pressure drag |

| Impact on Aerospace Design | Reduces drag, improves fuel efficiency; used in laminar flow wings and surfaces | Enhances control and stability in certain conditions; common in most aircraft flight scenarios |

| Energy Dissipation | Minimal energy loss | Higher energy loss due to turbulence |

| Flow Stability | Highly stable and predictable | Unstable and unpredictable |

Introduction to Laminar and Turbulent Flow

Laminar flow occurs when a fluid moves smoothly in parallel layers with minimal mixing, typically at low velocities and Reynolds numbers below 2,000. Turbulent flow, characterized by chaotic fluid motion and eddies, arises at higher velocities and Reynolds numbers exceeding 4,000, enhancing mixing and momentum transfer. Understanding the transition between laminar and turbulent flow is crucial for optimizing aerodynamic performance and fluid transport efficiency in engineering applications.

Fundamental Differences: Laminar vs Turbulent Flow

Laminar flow features smooth, orderly fluid motion with parallel layers and minimal mixing, characterized by low Reynolds numbers typically below 2,000. Turbulent flow exhibits chaotic, irregular movement with intense mixing, occurring at high Reynolds numbers generally above 4,000. The fundamental difference lies in flow stability and velocity fluctuations, where laminar flow maintains consistent velocity profiles and turbulent flow includes rapid velocity changes and eddies.

Key Parameters Influencing Flow Regimes

Key parameters influencing laminar and turbulent flow regimes include Reynolds number, fluid velocity, viscosity, and pipe diameter. Low Reynolds numbers, typically below 2,300, favor laminar flow where fluid particles move in smooth, orderly layers, while higher values promote turbulent flow characterized by chaotic and irregular fluctuations. Surface roughness and fluid density also impact the transition between laminar and turbulent states by affecting flow stability and energy dissipation rates.

Reynolds Number: Gateway to Flow Characterization

Reynolds Number serves as a critical parameter in distinguishing laminar flow, characterized by smooth, orderly fluid motion, from turbulent flow, marked by chaotic and irregular fluctuations. Values of Reynolds Number below approximately 2300 indicate laminar flow, while those exceeding 4000 typically signify turbulent conditions, with transitional flow occurring in between. Engineers and scientists use this dimensionless quantity to predict flow behavior in applications ranging from pipeline transport to aerodynamic design, ensuring optimized performance and stability.

Impact of Flow Type on Aerodynamic Efficiency

Laminar flow, characterized by smooth and orderly fluid motion, reduces skin friction drag and maximizes aerodynamic efficiency by maintaining a stable boundary layer over surfaces. Turbulent flow, with chaotic and irregular fluid movement, increases mixing and momentum transfer but significantly raises drag due to higher surface friction. Designing airfoils and vehicle shapes to sustain laminar flow zones can lead to improved fuel economy and enhanced performance in aerospace and automotive applications.

Surface Design Considerations in Aerospace Structures

Surface design in aerospace structures prioritizes minimizing turbulent flow to reduce drag and enhance fuel efficiency, often achieved through smooth, streamlined shapes and specialized coatings. Laminar flow promotes steady, orderly air movement, decreasing skin friction and improving aerodynamic performance, but maintaining it requires careful control of surface roughness and contamination. Advanced materials and precision manufacturing techniques are essential to sustain laminar flow and delay the transition to turbulence on critical aircraft surfaces.

Drag Reduction: Laminar vs Turbulent Boundaries

Laminar flow minimizes drag by maintaining smooth, orderly fluid motion that reduces frictional resistance along surfaces, whereas turbulent flow increases drag due to chaotic eddies and vortices enhancing momentum transfer and skin friction. The laminar boundary layer, characterized by low Reynolds numbers, provides a more stable velocity gradient that limits energy loss. In contrast, turbulent boundary layers, common at higher Reynolds numbers, induce greater drag despite their enhanced mixing capabilities.

Experimental Techniques for Flow Visualization

Particle Image Velocimetry (PIV) is a widely used experimental technique for visualizing laminar and turbulent flow by capturing particle motion within a fluid, providing detailed velocity field data. Laser Doppler Anemometry (LDA) enables non-intrusive measurement of flow velocity in both laminar and turbulent regimes by analyzing Doppler shifts of laser light scattered from tracer particles. Smoke or dye injection methods offer qualitative visualization of flow patterns, distinctly revealing the smooth streamlines in laminar flow and chaotic eddies characteristic of turbulence.

Real-World Applications in Aerospace Engineering

Laminar flow in aerospace engineering enhances aerodynamic efficiency by reducing skin friction drag on aircraft surfaces, leading to improved fuel economy and extended range. Turbulent flow, despite higher drag, is crucial for maintaining boundary layer stability over wings and control surfaces, preventing flow separation and potential loss of lift during critical flight maneuvers. Advanced surface coatings and flow control technologies are employed in modern aircraft design to manage the transition between laminar and turbulent flow, optimizing overall aerodynamic performance.

Future Trends in Flow Management for Aerospace

Laminar flow control in aerospace aims to reduce drag and improve fuel efficiency by maintaining smooth airflow over aircraft surfaces, leveraging advanced materials and surface coatings to delay transition to turbulence. Future trends include the integration of smart sensors and active flow control technologies that adapt in real-time to varying flight conditions, enhancing stability and reducing emissions. Computational fluid dynamics (CFD) and machine learning algorithms optimize aerodynamic designs to achieve better laminar flow control, driving innovations in next-generation aircraft performance.

Reynolds number

Reynolds number quantifies the transition between laminar flow at low values (typically below 2300) and turbulent flow at high values (above 4000), characterizing fluid flow behavior based on velocity, characteristic length, and kinematic viscosity.

Boundary layer transition

Boundary layer transition from laminar to turbulent flow occurs when increasing Reynolds number causes instabilities in the smooth laminar layer, significantly impacting drag and heat transfer rates.

Flow separation

Flow separation occurs earlier and more prominently in turbulent flow due to increased inertial forces, whereas laminar flow maintains attachment longer because of lower momentum exchange.

Skin friction drag

Laminar flow minimizes skin friction drag by maintaining smooth, orderly fluid motion near the surface, while turbulent flow increases skin friction drag due to chaotic, high-energy eddies disrupting the boundary layer.

Velocity profile

Laminar flow exhibits a smooth, parabolic velocity profile with maximum velocity at the center and zero at the boundary, while turbulent flow shows a flatter, fuller velocity profile with enhanced mixing and fluctuating velocities across the cross-section.

Pressure gradient

Laminar flow maintains a steady pressure gradient with smooth, orderly fluid motion, while turbulent flow exhibits fluctuating pressure gradients due to chaotic and irregular fluid movement.

Turbulent eddies

Turbulent flow is characterized by chaotic and irregular fluid motion dominated by turbulent eddies that enhance mixing and increase momentum and heat transfer rates compared to laminar flow.

Flow instability

Flow instability arises when laminar flow transitions to turbulent flow due to disturbances exceeding critical Reynolds number thresholds, causing chaotic fluid motion.

Laminar-turbulent intermittency

Laminar-turbulent intermittency occurs in fluid flow when smooth laminar regions alternate irregularly with chaotic turbulent regions, significantly impacting transition behavior and shear stress distribution.

Shear stress distribution

Laminar flow exhibits a linear shear stress distribution with low turbulence, while turbulent flow presents a complex, fluctuating shear stress profile due to chaotic fluid motion.

laminar flow vs turbulent flow Infographic

njnir.com

njnir.com