Boundary layer ingestion (BLI) enhances propulsion efficiency by ingesting slower-moving airflow near the aircraft surface, reducing overall drag and improving fuel economy. Conventional propulsion systems, positioned away from the fuselage, do not capitalize on boundary layer flow, resulting in less aerodynamic integration and higher fuel consumption. Integrating BLI requires advanced aerodynamic design to balance engine performance with airframe benefits, offering significant potential for reducing aircraft emissions in future aerospace engineering developments.

Table of Comparison

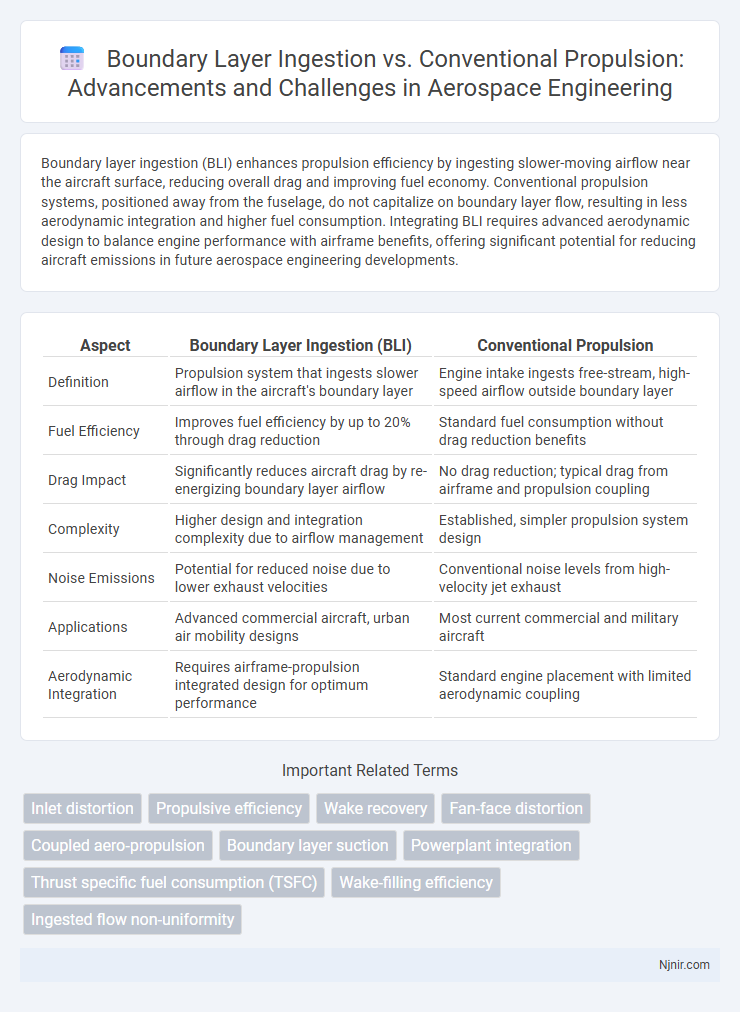

| Aspect | Boundary Layer Ingestion (BLI) | Conventional Propulsion |

|---|---|---|

| Definition | Propulsion system that ingests slower airflow in the aircraft's boundary layer | Engine intake ingests free-stream, high-speed airflow outside boundary layer |

| Fuel Efficiency | Improves fuel efficiency by up to 20% through drag reduction | Standard fuel consumption without drag reduction benefits |

| Drag Impact | Significantly reduces aircraft drag by re-energizing boundary layer airflow | No drag reduction; typical drag from airframe and propulsion coupling |

| Complexity | Higher design and integration complexity due to airflow management | Established, simpler propulsion system design |

| Noise Emissions | Potential for reduced noise due to lower exhaust velocities | Conventional noise levels from high-velocity jet exhaust |

| Applications | Advanced commercial aircraft, urban air mobility designs | Most current commercial and military aircraft |

| Aerodynamic Integration | Requires airframe-propulsion integrated design for optimum performance | Standard engine placement with limited aerodynamic coupling |

Introduction to Propulsion Systems in Aerospace Engineering

Boundary layer ingestion (BLI) enhances propulsion efficiency by integrating the engine intake with the aircraft's boundary layer airflow, reducing total drag and improving fuel consumption compared to conventional propulsion systems. Conventional propulsion typically relies on clean, free-stream air for engine intake, which limits potential aerodynamic and propulsive interactions. Incorporating BLI in aerospace engineering introduces complex flow dynamics and thermal challenges but offers significant opportunities for reducing aircraft emissions and optimizing overall propulsion system performance.

Fundamentals of Boundary Layer Ingestion (BLI)

Boundary layer ingestion (BLI) enhances propulsion efficiency by capturing and ingesting the slower-moving boundary layer airflow along the aircraft surface, reducing wake losses and increasing propulsive efficiency compared to conventional propulsion, which ingests free-stream air. BLI integrates the propulsion system within or near the aircraft's aerodynamic surfaces, leveraging the reduced velocity and turbulence characteristic of the boundary layer to decrease total drag and improve fuel efficiency. Understanding boundary layer thickness, velocity profiles, and flow characteristics is fundamental to designing effective BLI systems that optimize inlet shape, positioning, and fan performance for maximum drag reduction and thrust gain.

Overview of Conventional Aircraft Propulsion

Conventional aircraft propulsion typically relies on turbofan or turbojet engines mounted on the wings or fuselage, ingesting free-stream airflow with minimal distortion. These engines operate by accelerating ambient air through the compressor, combustor, and turbine stages to generate thrust, following well-established aerodynamic and thermodynamic principles. The propulsion systems are optimized for high efficiency and reliability under steady, undisturbed inlet flow conditions, which contrasts with the altered airflow environment characteristic of boundary layer ingestion configurations.

Aerodynamic Principles: BLI vs Conventional Propulsion

Boundary layer ingestion (BLI) enhances propulsion efficiency by capturing slower, high-drag airflow near the aircraft surface, reducing wake losses and improving overall thrust. Conventional propulsion ingests free-stream air with higher velocity but misses the opportunity to recover energy from the boundary layer, leading to increased drag and fuel consumption. Aerodynamic principles reveal that BLI integration reduces total aircraft drag by streamlining propulsion-airframe interaction, optimizing performance through improved momentum recovery.

Propulsive Efficiency Comparison

Boundary layer ingestion (BLI) improves propulsive efficiency by recovering slower, boundary-layer airflow around the aircraft, reducing total drag and enhancing thrust. Conventional propulsion expels high-velocity exhaust into free stream, often resulting in lower overall efficiency due to higher momentum loss. Studies indicate BLI configurations can achieve up to 10-20% improvement in propulsive efficiency compared to traditional turbofan engines.

Impact on Fuel Consumption and Emissions

Boundary layer ingestion (BLI) enhances propulsion efficiency by ingesting slower-moving air close to the aircraft surface, reducing the energy required to accelerate the airflow, which significantly lowers fuel consumption compared to conventional propulsion systems. This reduction in fuel burn directly correlates with decreased greenhouse gas emissions, making BLI a pivotal technology for sustainable aviation. Studies indicate BLI can improve propulsive efficiency by up to 15%, resulting in emissions reductions of approximately 10-20% per flight, positioning it as a critical innovation for meeting future environmental regulations.

Design Challenges and Solutions for BLI

Boundary Layer Ingestion (BLI) propulsion integrates the engine intake with the aircraft's boundary layer flow to improve fuel efficiency by reducing drag and increasing propulsive efficiency. Design challenges for BLI include managing distorted and low-momentum airflow, preventing engine stall, and ensuring structural integration without compromising airframe performance. Solutions involve advanced inlet designs with flow control technologies, careful aerodynamic shaping to smooth boundary layer ingestion, and robust engine control systems that adapt to variable inlet conditions.

Integration and Structural Considerations

Boundary layer ingestion (BLI) propulsion integrates the engine closely with the airframe, reducing drag by ingesting slower-moving boundary layer air, which necessitates advanced structural designs to handle non-uniform flow and increased thermal loads. This integration demands reinforced nacelle structures and optimized load paths to maintain airframe integrity while minimizing weight penalties. Conventional propulsion, by contrast, features externally mounted engines with standardized interfaces, simplifying structural design but offering less potential for aerodynamic efficiency improvements.

Real-World Applications and Case Studies

Boundary layer ingestion (BLI) enhances propulsion efficiency by integrating engine inlets with the aircraft surface, reducing drag and improving fuel consumption in real-world applications such as NASA's X-57 Maxwell electric plane and Lockheed Martin's STOL concept aircraft. Conventional propulsion relies on independently mounted engines, resulting in higher drag and less optimal fuel efficiency but offers proven reliability in current commercial airliners like the Boeing 737 and Airbus A320. Case studies reveal BLI's potential for up to 10-20% fuel savings in short- to medium-range aircraft, while conventional propulsion maintains dominance due to established infrastructure and certification standards.

Future Trends and Research Directions

Future trends in boundary layer ingestion (BLI) focus on enhancing aircraft fuel efficiency and reducing emissions by integrating propulsion systems with airframe designs to ingest slower-moving boundary layer air. Research directions emphasize improving computational fluid dynamics models to optimize BLI ducting and mitigate distortion effects on engines while advancing hybrid-electric and distributed propulsion technologies to maximize the benefits of BLI. Ongoing studies also explore adaptive control strategies and advanced materials to improve reliability and performance in diverse flight conditions compared to conventional propulsion systems.

Inlet distortion

Boundary layer ingestion propulsion reduces inlet distortion by ingesting slower-moving airflow near the aircraft surface, enhancing engine efficiency compared to conventional propulsion with cleaner, higher-velocity inlet flow.

Propulsive efficiency

Boundary layer ingestion propulsion enhances propulsive efficiency by recovering low-energy airflow near the aircraft surface, reducing wake losses compared to conventional propulsion systems.

Wake recovery

Boundary layer ingestion propulsion enhances wake recovery by ingesting slower-moving air near the aircraft surface, increasing propulsive efficiency compared to conventional propulsion systems that operate in faster, less disturbed airflow.

Fan-face distortion

Boundary layer ingestion propulsion significantly reduces fan-face distortion compared to conventional propulsion by ingesting slower-moving airflow near the aircraft surface, enhancing overall propulsive efficiency.

Coupled aero-propulsion

Coupled aero-propulsion in boundary layer ingestion systems enhances fuel efficiency by integrating aircraft boundary layer airflow directly into propulsion, reducing drag and improving thrust compared to conventional propulsion methods.

Boundary layer suction

Boundary layer suction enhances boundary layer ingestion by actively removing low-energy airflow near the surface, improving propulsion efficiency and reducing drag compared to conventional propulsion systems.

Powerplant integration

Boundary layer ingestion enhances powerplant integration by reducing inlet losses and improving propulsion efficiency compared to conventional propulsion systems with separated engine placements.

Thrust specific fuel consumption (TSFC)

Boundary layer ingestion propulsion reduces thrust specific fuel consumption (TSFC) by up to 20% compared to conventional propulsion due to improved aerodynamic efficiency and reduced wake losses.

Wake-filling efficiency

Boundary layer ingestion propulsion increases wake-filling efficiency by recovering low-energy airflow near the aircraft surface, reducing drag and enhancing overall fuel efficiency compared to conventional propulsion systems.

Ingested flow non-uniformity

Boundary layer ingestion propulsion faces significant challenges due to the non-uniformity of ingested flow, which reduces efficiency and complicates engine performance compared to conventional propulsion systems that intake uniform airflow.

Boundary layer ingestion vs Conventional propulsion Infographic

njnir.com

njnir.com