Air-breathing engines utilize atmospheric oxygen for combustion, offering greater efficiency and longer operational duration compared to rocket engines, which carry both fuel and oxidizer onboard. These engines excel in environments with abundant air, such as within Earth's atmosphere, reducing the weight and complexity associated with carrying oxidizers. Rocket engines, however, provide superior thrust and operate independently of atmospheric conditions, making them essential for space travel and high-altitude missions.

Table of Comparison

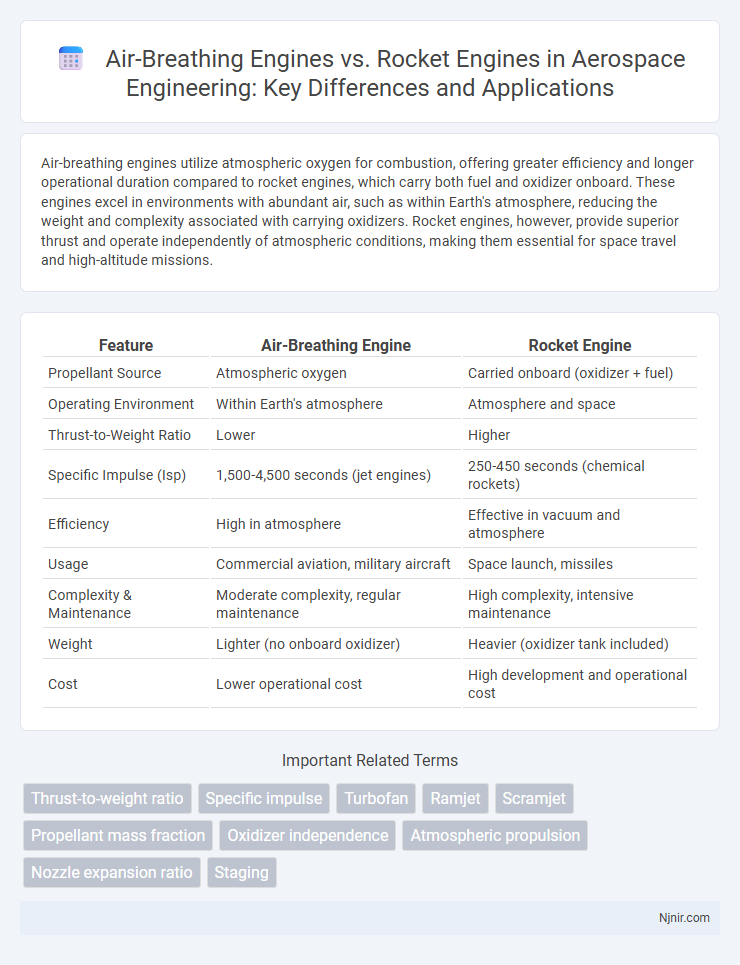

| Feature | Air-Breathing Engine | Rocket Engine |

|---|---|---|

| Propellant Source | Atmospheric oxygen | Carried onboard (oxidizer + fuel) |

| Operating Environment | Within Earth's atmosphere | Atmosphere and space |

| Thrust-to-Weight Ratio | Lower | Higher |

| Specific Impulse (Isp) | 1,500-4,500 seconds (jet engines) | 250-450 seconds (chemical rockets) |

| Efficiency | High in atmosphere | Effective in vacuum and atmosphere |

| Usage | Commercial aviation, military aircraft | Space launch, missiles |

| Complexity & Maintenance | Moderate complexity, regular maintenance | High complexity, intensive maintenance |

| Weight | Lighter (no onboard oxidizer) | Heavier (oxidizer tank included) |

| Cost | Lower operational cost | High development and operational cost |

Introduction to Air-Breathing and Rocket Engines

Air-breathing engines, such as turbofans and ramjets, intake atmospheric oxygen to combust fuel, enabling efficient propulsion within Earth's atmosphere. Rocket engines carry both fuel and oxidizer onboard, allowing operation in the vacuum of space by generating thrust through controlled combustion. Understanding these fundamental differences reveals why air-breathing engines dominate atmospheric flight while rocket engines are essential for space travel.

Fundamental Operating Principles

Air-breathing engines operate by ingesting atmospheric oxygen to combust onboard fuel, utilizing compressors and turbines to generate thrust efficiently within Earth's atmosphere. Rocket engines carry both fuel and an oxidizer, enabling combustion in the vacuum of space by expelling high-speed exhaust gases through a nozzle to produce thrust. The fundamental difference lies in air-breathing engines relying on external oxygen for combustion, whereas rocket engines are self-contained propulsion systems capable of functioning beyond atmospheric boundaries.

Types of Air-Breathing Engines

Turbojet, turbofan, ramjet, scramjet, and pulsejet constitute the primary types of air-breathing engines, each optimized for different flight regimes and speeds. Turbojets and turbofans dominate commercial aviation due to their fuel efficiency and thrust capabilities at subsonic and transonic speeds, while ramjets and scramjets excel at supersonic and hypersonic speeds, leveraging high-velocity airflow for combustion without compressor stages. Pulsejets, though less common, are valued for their simplicity and usage in specific applications such as drones or experimental aircraft.

Types of Rocket Engines

Rocket engines can be broadly classified into liquid-propellant, solid-propellant, and hybrid engines, each using different fuel and oxidizer combinations to generate thrust. Liquid-propellant rockets offer precise thrust control and higher efficiency, whereas solid-propellant rockets are simpler and more reliable with rapid ignition. Hybrid engines combine elements of both, using a liquid oxidizer and solid fuel to balance controllability and simplicity, making them versatile for various aerospace applications.

Performance Comparison: Thrust and Efficiency

Air-breathing engines generate thrust by compressing and combusting atmospheric air, resulting in higher fuel efficiency at lower speeds and altitudes, typically reaching specific impulse values around 3,000 seconds. Rocket engines carry both fuel and oxidizer, enabling operation in space with thrust levels far exceeding air-breathing engines, often producing thrust over 1,000 kN but with lower specific impulse, generally between 250 and 450 seconds. The trade-off between thrust and efficiency makes air-breathing engines ideal for atmospheric flight, while rocket engines excel in high-thrust, high-altitude, and vacuum conditions.

Applications in Aerospace Vehicles

Air-breathing engines, such as turbojets and ramjets, are primarily used in aircraft and hypersonic vehicles due to their ability to efficiently intake atmospheric oxygen, enabling prolonged flight within Earth's atmosphere. Rocket engines, which carry both fuel and oxidizer onboard, are essential for space launch vehicles and deep-space missions where atmospheric oxygen is unavailable. The combination of these engines in some aerospace designs maximizes performance by leveraging air-breathing propulsion during initial ascent and transitioning to rocket propulsion in space.

Propellant Requirements and Fuel Efficiency

Air-breathing engines utilize atmospheric oxygen to combust fuel, significantly reducing onboard oxidizer storage and enhancing fuel efficiency in Earth's atmosphere. Rocket engines must carry both fuel and oxidizer, resulting in higher propellant mass and lower specific impulse compared to air-breathing engines. The reliance on external oxygen makes air-breathing engines more efficient for lower-speed applications, while rocket engines excel in high-speed, high-altitude, and vacuum conditions despite increased propellant demands.

Altitude and Speed Capabilities

Air-breathing engines, such as turbojets and ramjets, operate efficiently at lower altitudes up to approximately 25 kilometers and speeds up to Mach 6 by utilizing atmospheric oxygen for combustion. Rocket engines can function at all altitudes, including the vacuum of space, enabling speeds exceeding Mach 25 due to onboard oxidizers allowing combustion independent of atmospheric conditions. The altitude and speed capabilities of air-breathing engines are limited by oxygen availability and air density, whereas rocket engines are optimized for high-altitude and orbital or interplanetary velocities.

Technological Challenges and Innovations

Air-breathing engines face challenges in efficiently compressing and combusting atmospheric air at hypersonic speeds, requiring innovations like pre-cooling technology and advanced materials to withstand extreme temperatures and pressures. Rocket engines confront the complexities of managing cryogenic propellants and achieving stable combustion in vacuum conditions, driving developments in turbopumps and regenerative cooling systems. Both engine types benefit from computational fluid dynamics advancements and additive manufacturing techniques to optimize design and performance under harsh operational environments.

Future Trends in Propulsion Systems

Future trends in propulsion systems emphasize the integration of air-breathing engines with rocket engines to enhance efficiency and extend mission capabilities. Air-breathing engines, such as scramjets and ramjets, are advancing to operate at higher speeds and altitudes, reducing the need for onboard oxidizers and lowering launch costs. Hybrid propulsion designs combining air-breathing technology with rocket engines show promise for reusable spaceplanes and hypersonic travel, pushing the boundaries of aerospace innovation.

Thrust-to-weight ratio

Air-breathing engines typically have a higher thrust-to-weight ratio than rocket engines due to their reliance on atmospheric oxygen, reducing onboard oxidizer mass.

Specific impulse

Air-breathing engines achieve higher specific impulse by using atmospheric oxygen for combustion, unlike rocket engines that carry onboard oxidizers, resulting in heavier propellant load and lower overall efficiency.

Turbofan

Turbofan engines offer higher fuel efficiency and sustained thrust by utilizing atmospheric oxygen for combustion, unlike rocket engines that carry oxidizers and excel in thrust-to-weight ratio and space propulsion.

Ramjet

Ramjets, unlike traditional rocket engines, utilize atmospheric oxygen for combustion, enabling higher efficiency and lighter design for high-speed air-breathing propulsion without onboard oxidizers.

Scramjet

Scramjet engines achieve hypersonic speeds by compressing incoming air at supersonic velocities for efficient combustion, unlike traditional rocket engines that carry both fuel and oxidizer.

Propellant mass fraction

Air-breathing engines have a significantly lower propellant mass fraction compared to rocket engines because they utilize atmospheric oxygen, reducing the need to carry oxidizer onboard and thereby increasing payload capacity.

Oxidizer independence

Air-breathing engines utilize atmospheric oxygen as an oxidizer, enabling fuel efficiency and reduced onboard oxidizer weight, while rocket engines carry their own oxidizer, providing independence from atmospheric conditions but increasing total vehicle mass.

Atmospheric propulsion

Air-breathing engines utilize atmospheric oxygen for combustion, enabling efficient propulsion within Earth's atmosphere, while rocket engines carry onboard oxidizers to operate independently of atmospheric conditions.

Nozzle expansion ratio

Air-breathing engines feature lower nozzle expansion ratios optimized for atmospheric pressure, while rocket engines utilize higher nozzle expansion ratios to maximize performance in the vacuum of space.

Staging

Air-breathing engines enable single-stage-to-orbit designs by using atmospheric oxygen during initial flight phases, whereas rocket engines require multi-stage configurations due to carrying oxidizers onboard for operation beyond the atmosphere.

air-breathing engine vs rocket engine Infographic

njnir.com

njnir.com