Ion propulsion offers significantly higher fuel efficiency and longer mission durations than traditional chemical propulsion, making it ideal for deep-space exploration. Chemical propulsion provides greater thrust and rapid acceleration, essential for launch and quick maneuvers within planetary atmospheres. The choice between ion and chemical propulsion depends on mission objectives, where ion thrusters excel in sustained travel and chemical rockets dominate in initial lift-off and high-energy requirements.

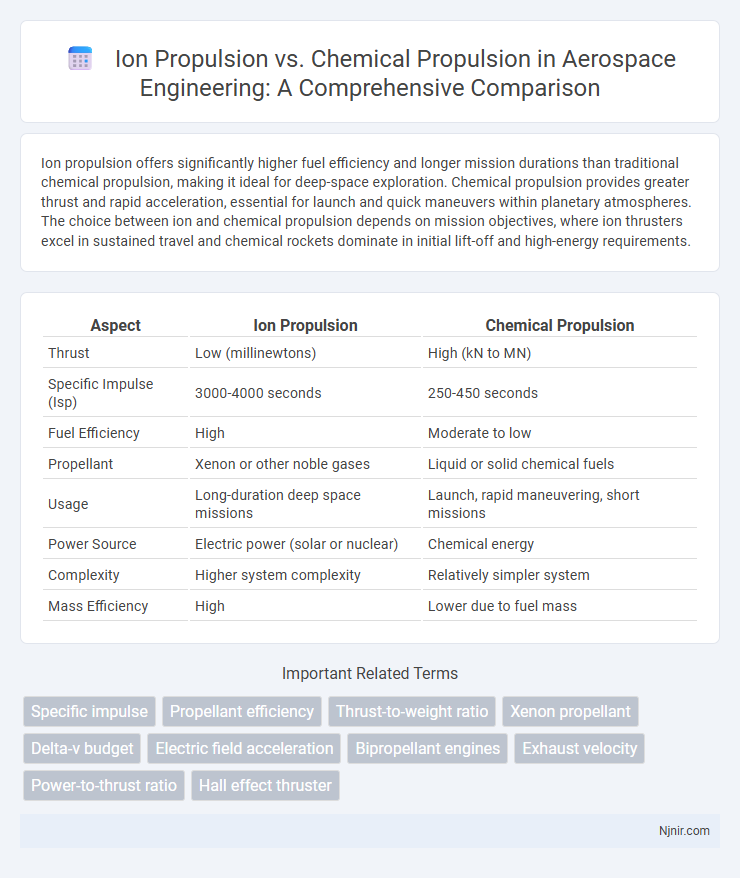

Table of Comparison

| Aspect | Ion Propulsion | Chemical Propulsion |

|---|---|---|

| Thrust | Low (millinewtons) | High (kN to MN) |

| Specific Impulse (Isp) | 3000-4000 seconds | 250-450 seconds |

| Fuel Efficiency | High | Moderate to low |

| Propellant | Xenon or other noble gases | Liquid or solid chemical fuels |

| Usage | Long-duration deep space missions | Launch, rapid maneuvering, short missions |

| Power Source | Electric power (solar or nuclear) | Chemical energy |

| Complexity | Higher system complexity | Relatively simpler system |

| Mass Efficiency | High | Lower due to fuel mass |

Introduction to Propulsion Systems in Aerospace Engineering

Ion propulsion offers higher specific impulse and fuel efficiency compared to chemical propulsion, making it ideal for long-duration space missions. Chemical propulsion provides higher thrust needed for launch and rapid acceleration by combusting propellants, enabling spacecraft to overcome Earth's gravity. Aerospace engineering balances these propulsion systems to optimize mission profiles based on thrust requirements, fuel efficiency, and mission duration.

Fundamental Principles of Ion Propulsion

Ion propulsion operates by expelling ions at high velocities using electric fields generated through electromagnetic forces, achieving significantly higher specific impulse compared to chemical propulsion. Unlike chemical propulsion, which relies on combustion reactions to produce thrust via rapid expansion of gases, ion thrusters accelerate charged particles in a vacuum to generate continuous, low-thrust propulsion. The fundamental principle centers on ionizing a propellant gas such as xenon and using electrostatic grids or electromagnetic fields to produce a controlled, efficient thrust ideal for long-duration space missions.

Core Mechanisms of Chemical Propulsion

Chemical propulsion relies on rapid combustion of propellants, producing high-pressure and high-temperature gases that generate thrust through expansion in a nozzle. This exothermic reaction between fuel and oxidizer creates a controlled explosion, converting chemical energy into kinetic energy. Unlike ion propulsion, chemical propulsion offers high thrust and rapid acceleration suitable for launch and quick maneuvers.

Efficiency and Specific Impulse Comparison

Ion propulsion systems achieve significantly higher efficiency and specific impulse compared to chemical propulsion, with specific impulses often exceeding 3,000 seconds versus 300-450 seconds for chemical rockets. This higher specific impulse translates to more effective fuel consumption, allowing spacecraft to achieve greater velocities over extended missions with less propellant. Although ion thrusters produce lower thrust, their superior fuel efficiency makes them ideal for deep-space missions requiring sustained, efficient propulsion.

Thrust Capabilities and Mission Profiles

Ion propulsion offers significantly lower thrust compared to chemical propulsion, producing millinewtons of force suitable for gradual acceleration over extended periods. Chemical propulsion generates high thrust in the range of thousands of newtons, enabling rapid velocity changes critical for launch and quick maneuvering. Ion thrusters excel in deep-space missions requiring efficient long-duration propulsion, while chemical engines dominate short-duration, high-thrust mission profiles such as launch and planetary ascent.

Propellant Types and Usage

Ion propulsion systems use inert gases such as xenon or krypton as propellants, which are ionized and accelerated to generate thrust with high efficiency and minimal propellant mass. Chemical propulsion relies on liquid or solid propellants like hydrazine, liquid oxygen, or kerosene, offering high thrust suitable for rapid acceleration and heavy payload launch. Ion propulsion excels in long-duration missions with low thrust but superior fuel economy, while chemical propulsion supports short-term, high-thrust maneuvers essential for launch and orbital insertion.

Power Requirements and System Integration

Ion propulsion systems require significantly lower power levels compared to chemical propulsion but demand high-efficiency power sources such as solar arrays or nuclear reactors to maintain continuous thrust. Integrating ion thrusters involves complex thermal management and power conditioning units to handle precise voltage and current control, ensuring stable ionization and acceleration of propellant ions. Chemical propulsion systems, by contrast, integrate combustion chambers and turbopumps that handle high instantaneous power densities and thermal loads, necessitating robust structural materials and simpler power electronics focused on start-up and valve control.

Applications in Space Missions: Past and Present

Ion propulsion has been extensively utilized in deep-space missions such as NASA's Dawn spacecraft, which explored the asteroid Vesta and dwarf planet Ceres, showcasing its efficiency for long-duration, low-thrust applications. Chemical propulsion remains the preferred choice for launching payloads from Earth and for missions requiring high thrust, exemplified by the Space Shuttle and Falcon 9 rockets. Current trends indicate growing adoption of ion thrusters for satellite station-keeping and interplanetary missions due to their high fuel efficiency and extended operational lifespans.

Advantages and Limitations of Each Propulsion Method

Ion propulsion offers high fuel efficiency and extended operational lifespan, making it ideal for deep-space missions requiring minimal propellant mass. Chemical propulsion provides high thrust and rapid acceleration, enabling quick maneuvers and effective escape velocity from planetary bodies. However, ion propulsion suffers from low thrust levels limiting its use for launch or short-duration missions, while chemical propulsion's reliance on large fuel quantities restricts mission duration and increases spacecraft weight.

Future Trends in Aerospace Propulsion Technologies

Ion propulsion technology offers significantly higher fuel efficiency and longer operational lifespans compared to traditional chemical propulsion, making it ideal for deep space missions and satellite station-keeping. Emerging hybrid propulsion systems aim to combine the high thrust of chemical engines with the efficiency of ion thrusters, enhancing versatility for diverse mission profiles. Advances in materials science and power generation, such as nuclear and solar-electric power sources, are expected to further improve ion propulsion performance and enable more sustainable, cost-effective space exploration.

Specific impulse

Ion propulsion achieves a specific impulse up to 10 times higher than chemical propulsion, enabling more efficient fuel consumption for long-duration space missions.

Propellant efficiency

Ion propulsion achieves higher propellant efficiency than chemical propulsion by expelling ions at much greater velocities, resulting in significantly improved specific impulse and reduced fuel consumption.

Thrust-to-weight ratio

Ion propulsion systems typically have a lower thrust-to-weight ratio compared to chemical propulsion but offer significantly higher specific impulse and efficiency for long-duration space missions.

Xenon propellant

Ion propulsion using xenon propellant offers higher fuel efficiency and longer mission durations compared to traditional chemical propulsion due to its superior specific impulse and lower propellant consumption.

Delta-v budget

Ion propulsion provides a significantly higher Delta-v budget than chemical propulsion by offering greater fuel efficiency and prolonged thrust duration, making it ideal for deep-space missions.

Electric field acceleration

Ion propulsion achieves higher efficiency than chemical propulsion by accelerating ions using electric fields, enabling prolonged thrust with minimal propellant consumption.

Bipropellant engines

Bipropellant engines in ion propulsion offer higher specific impulse and fuel efficiency compared to conventional chemical bipropellant engines, enabling longer mission durations and reduced propellant mass.

Exhaust velocity

Ion propulsion achieves exhaust velocities up to 30-50 km/s, significantly surpassing chemical propulsion's typical exhaust velocity of 2-4.5 km/s, enhancing fuel efficiency and spacecraft range.

Power-to-thrust ratio

Ion propulsion systems exhibit a significantly higher power-to-thrust ratio compared to chemical propulsion, enabling more efficient fuel use and longer mission durations despite producing lower immediate thrust.

Hall effect thruster

Hall effect thruster ion propulsion systems offer higher fuel efficiency and longer operational lifespans compared to traditional chemical propulsion by accelerating ions through electromagnetic fields for deep-space missions.

ion propulsion vs chemical propulsion Infographic

njnir.com

njnir.com