Supersonic combustion occurs at speeds exceeding Mach 1, enabling more efficient propulsion in scramjet engines by sustaining combustion in supersonic airflow, which reduces drag and increases thrust. Subsonic combustion operates at speeds below Mach 1, commonly used in traditional jet engines, relying on slower airflow to mix fuel and air thoroughly for stable ignition. The primary advantage of supersonic combustion lies in achieving higher speeds and improved fuel efficiency for hypersonic flight, while subsonic combustion remains more practical for conventional aerospace applications due to simpler engine design and control.

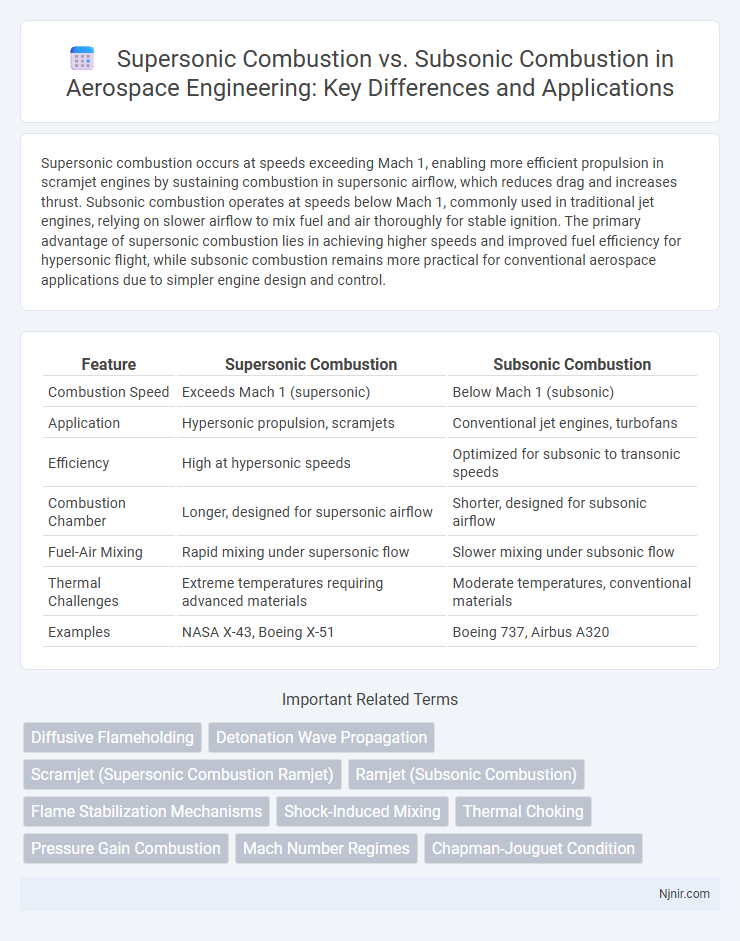

Table of Comparison

| Feature | Supersonic Combustion | Subsonic Combustion |

|---|---|---|

| Combustion Speed | Exceeds Mach 1 (supersonic) | Below Mach 1 (subsonic) |

| Application | Hypersonic propulsion, scramjets | Conventional jet engines, turbofans |

| Efficiency | High at hypersonic speeds | Optimized for subsonic to transonic speeds |

| Combustion Chamber | Longer, designed for supersonic airflow | Shorter, designed for subsonic airflow |

| Fuel-Air Mixing | Rapid mixing under supersonic flow | Slower mixing under subsonic flow |

| Thermal Challenges | Extreme temperatures requiring advanced materials | Moderate temperatures, conventional materials |

| Examples | NASA X-43, Boeing X-51 | Boeing 737, Airbus A320 |

Introduction to Combustion Regimes in Aerospace Propulsion

Supersonic combustion occurs at flow velocities exceeding the speed of sound within the combustion chamber, enabling scramjet engines to achieve high efficiency at hypersonic speeds above Mach 5, while subsonic combustion operates below sonic speeds typical in conventional ramjets. The distinct combustion regimes influence flame stability, ignition delay, and fuel-air mixing, making supersonic combustion critical for sustained propulsion in hypersonic aerospace applications. Understanding the differences in pressure, temperature profiles, and combustion kinetics between these regimes is essential for designing advanced propulsion systems that optimize performance and reduce thermal loads.

Fundamentals of Subsonic and Supersonic Combustion

Subsonic combustion involves flame propagation at speeds slower than the speed of sound, characterized by relatively low-temperature gradients and steady pressure fields, typically occurring in conventional jet engines and gas turbines. Supersonic combustion, or scramjet combustion, occurs at speeds exceeding the speed of sound, with rapid mixing and chemical reactions happening in milliseconds under high-velocity airflow, enabling efficient propulsion at hypersonic speeds. The fundamental difference lies in flow dynamics and combustion stability, where subsonic combustion relies on pressure-driven flame propagation, while supersonic combustion requires precise control of shock waves, fuel-air mixing, and ignition to sustain a stable flame in supersonic airflow.

Thermodynamic Principles Affecting Combustion Modes

Supersonic combustion occurs at flow velocities exceeding the speed of sound, significantly influenced by shock waves and rapid compression in scramjet engines, leading to higher temperature and pressure gradients that enhance fuel-air mixing and reaction rates. Subsonic combustion operates at velocities below the speed of sound, where slower flow allows more complete combustion and stable flame propagation under steady-state thermodynamic conditions. The fundamental thermodynamic difference lies in the interaction between flow velocity and chemical kinetics, where supersonic combustion must balance extremely short residence times with efficient energy release to achieve thrust.

Flow Characteristics in Subsonic and Supersonic Combustors

Supersonic combustion occurs at velocities exceeding the speed of sound, where the flow remains supersonic throughout the combustor, leading to extremely rapid mixing and reaction rates within a thin shear layer. Subsonic combustion involves slower flow speeds below Mach 1, allowing for longer residence times, more stable flame anchoring, and more thorough mixing due to turbulent structures. Flow characteristics in supersonic combustors emphasize shock wave interactions and minimal boundary layer growth, whereas subsonic combustors rely on recirculation zones and controlled turbulence to sustain combustion.

Key Differences: Supersonic versus Subsonic Combustion

Supersonic combustion occurs when fuel burns at speeds exceeding the speed of sound, typically within scramjet engines, enabling efficient high-speed airbreathing propulsion above Mach 5. Subsonic combustion, used in traditional jet engines, involves fuel burning at speeds below the speed of sound, providing stable thrust at lower supersonic or subsonic speeds. The key difference lies in the combustion speed relative to the flow, where supersonic combustion allows for faster acceleration and higher-speed flight, while subsonic combustion prioritizes stability and control at lower velocities.

Application in Engine Types: Turbojets, Ramjets, and Scramjets

Supersonic combustion occurs in scramjet engines, where airflow remains supersonic through the combustion chamber, enabling efficient high-speed propulsion at hypersonic velocities above Mach 5. Subsonic combustion takes place in turbojets and ramjets, with turbojets relying on subsonic airflow throughout the engine and ramjets slowing airflow to subsonic speeds before combustion, suitable for speeds up to Mach 4. The choice between supersonic and subsonic combustion impacts engine design, fuel efficiency, and operational speed ranges critical to aerospace propulsion systems.

Challenges in Achieving Efficient Supersonic Combustion

Efficient supersonic combustion faces challenges such as maintaining stable flame ignition and controlling rapid chemical reactions within extremely short residence times, typically milliseconds, required in scramjet engines. High-temperature gradients and shock-wave interactions complicate fuel-air mixing, causing combustion inefficiencies and potential engine unstart. Advanced strategies like optimized fuel injection, enhanced turbulence management, and real-time sensing technologies are critical to overcoming these obstacles and achieving reliable supersonic combustion performance.

Advancements in Combustor Design for Supersonic Flow

Advancements in supersonic combustor design emphasize direct fuel injection and enhanced flame stabilization within shockwave-rich environments, utilizing flame holders and cavity geometries to maintain stable combustion at high Mach numbers. Innovations in thermal management and materials technology enable combustion chambers to withstand extreme temperatures and pressures inherent in supersonic flows, improving efficiency and durability. Computational fluid dynamics (CFD) simulations play a critical role in optimizing airflow mixing and minimizing pressure losses, accelerating the development of scramjet engines for hypersonic propulsion.

Performance Implications and Efficiency Analysis

Supersonic combustion, utilized in scramjet engines, enables airflows to remain supersonic throughout the combustion process, significantly enhancing thrust and speed capabilities beyond Mach 5, compared to subsonic combustion commonly found in turbojets and ramjets where airflow slows below Mach 1 for combustion. Performance implications of supersonic combustion include reduced residence time for fuel-air mixing, necessitating advanced fuel injection and ignition techniques to ensure efficient combustion, while subsonic combustion allows longer mixing times but limits maximum achievable speeds. Efficiency analysis reveals that supersonic combustion offers higher specific impulse at hypersonic speeds and improved fuel efficiency at extreme velocities, whereas subsonic combustion delivers better thermal efficiency at lower speeds but suffers from increased drag and heat losses at high Mach numbers.

Future Trends in Aerospace Propulsion Combustion Technologies

Supersonic combustion, characterized by airflow velocities exceeding the speed of sound within the combustion chamber, promises higher thermal efficiencies and thrust-to-weight ratios critical for hypersonic flight and next-generation scramjet engines. Subsonic combustion remains integral to traditional turbojet and turbofan engines due to its stable flame characteristics and fuel flexibility but faces limitations in high-speed aerospace applications. Future trends emphasize hybrid propulsion systems combining supersonic combustion for high-speed phases with subsonic combustion for low-speed efficiency, alongside advanced materials and additive manufacturing enabling resilient combustors capable of withstanding extreme thermal and mechanical stresses inherent in supersonic combustion regimes.

Diffusive Flameholding

Supersonic combustion relies on diffusive flameholding mechanisms to sustain stable flames in high-velocity flows unlike subsonic combustion, which typically uses premixed flames for more controlled and efficient burning.

Detonation Wave Propagation

Supersonic combustion features detonation wave propagation with shock-induced chemical reactions enabling rapid fuel oxidation, whereas subsonic combustion relies on slower deflagration waves with gradual flame fronts.

Scramjet (Supersonic Combustion Ramjet)

Scramjet engines achieve efficient hypersonic propulsion by maintaining supersonic airflow through the combustion chamber, unlike subsonic combustion ramjets that slow the airflow to subsonic speeds, resulting in faster fuel ignition and higher thermal efficiency at speeds above Mach 5.

Ramjet (Subsonic Combustion)

Ramjet engines utilize subsonic combustion to efficiently accelerate airflow within the combustion chamber at speeds below Mach 1, contrasting with supersonic combustion in scramjets that maintain supersonic airflow to achieve hypersonic velocities.

Flame Stabilization Mechanisms

Supersonic combustion relies on shock-induced recirculation zones and turbulent mixing for flame stabilization, whereas subsonic combustion primarily depends on stable flame anchors and slower chemical reaction rates to maintain flame stability.

Shock-Induced Mixing

Shock-induced mixing in supersonic combustion enhances fuel-air interaction efficiency, whereas subsonic combustion relies on slower diffusion processes resulting in less effective mixing.

Thermal Choking

Supersonic combustion prevents thermal choking by maintaining supersonic flow speeds in the combustor, whereas subsonic combustion often experiences thermal choking due to heat addition causing flow deceleration and pressure rise.

Pressure Gain Combustion

Supersonic combustion in scramjet engines achieves pressure gain combustion by sustaining stable flame propagation at hypersonic speeds, unlike subsonic combustion which results in pressure losses due to slower flame speeds and longer residence times.

Mach Number Regimes

Supersonic combustion occurs at Mach numbers greater than 1, enabling rapid fuel-air mixing in scramjets, whereas subsonic combustion operates below Mach 1, typical of conventional jet engines with slower flame propagation.

Chapman-Jouguet Condition

Supersonic combustion achieves the Chapman-Jouguet condition by maintaining a detonation wave speed matching the flow velocity, whereas subsonic combustion operates below this speed allowing pressure equilibrium ahead of the flame.

Supersonic Combustion vs Subsonic Combustion Infographic

njnir.com

njnir.com