Aerospike nozzles maintain optimal efficiency across a wide range of altitudes by dynamically adjusting the exhaust flow, unlike bell nozzles which are designed for peak performance at specific conditions. The unique geometry of aerospike nozzles reduces altitude losses and improves thrust efficiency, making them ideal for variable flight profiles. While bell nozzles benefit from simpler design and manufacturing, aerospike nozzles offer superior performance in multi-stage and reusable launch vehicle applications.

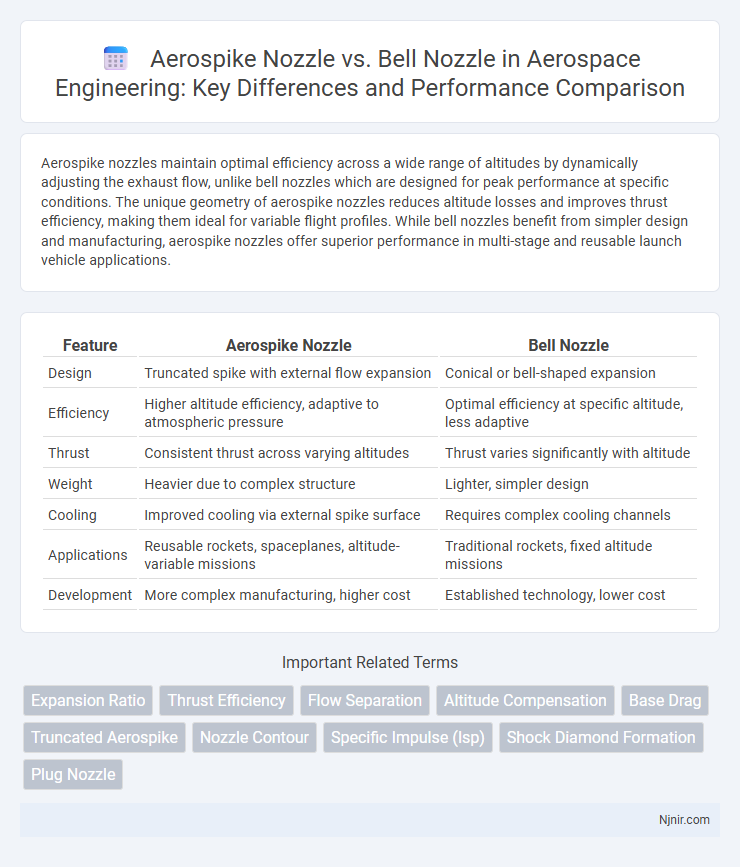

Table of Comparison

| Feature | Aerospike Nozzle | Bell Nozzle |

|---|---|---|

| Design | Truncated spike with external flow expansion | Conical or bell-shaped expansion |

| Efficiency | Higher altitude efficiency, adaptive to atmospheric pressure | Optimal efficiency at specific altitude, less adaptive |

| Thrust | Consistent thrust across varying altitudes | Thrust varies significantly with altitude |

| Weight | Heavier due to complex structure | Lighter, simpler design |

| Cooling | Improved cooling via external spike surface | Requires complex cooling channels |

| Applications | Reusable rockets, spaceplanes, altitude-variable missions | Traditional rockets, fixed altitude missions |

| Development | More complex manufacturing, higher cost | Established technology, lower cost |

Introduction to Rocket Nozzles

Rocket nozzles, essential for directing exhaust gases to generate thrust, come primarily in two designs: aerospike and bell nozzles. The aerospike nozzle maintains efficient performance across a range of altitudes by using an external spike to shape the exhaust plume, whereas the bell nozzle optimizes thrust at a specific altitude with a curved contour design. Understanding the aerodynamic and thermodynamic differences between these nozzles is crucial for selecting the appropriate propulsion system in aerospace applications.

Fundamentals of Bell Nozzle Design

Bell nozzles are designed based on the principles of efficient expansion of exhaust gases to maximize thrust, with a contour that gradually diverges to reduce flow separation and shock losses. Their design parameters include expansion ratio, throat diameter, and exit angle, which are optimized to balance internal flow dynamics and external atmospheric pressure. Compared to aerospike nozzles, bell nozzles offer simplicity and proven performance at specific altitudes but lack altitude-compensating efficiency inherent to aerospikes.

Overview of Aerospike Nozzle Architecture

The aerospike nozzle features a truncated spike that allows exhaust gases to expand along its surface, maintaining optimal pressure throughout varying altitudes by adjusting to ambient conditions. Unlike the traditional bell nozzle, which relies on a fixed contour, the aerospike's innovative design reduces flow separation and enhances thrust efficiency. Its architecture supports altitude compensation, improving overall rocket engine performance during ascent.

Thrust Efficiency: Bell vs Aerospike

Aerospike nozzles maintain higher thrust efficiency across a wide range of altitudes by continuously adapting their exhaust flow to ambient pressure, unlike traditional bell nozzles, which are optimized for a specific altitude, leading to decreased performance outside their design point. The altitude-compensating design of aerospike nozzles reduces flow separation and pressure losses, resulting in improved specific impulse especially during ascent. Bell nozzles, while simpler and proven, experience over-expansion or under-expansion at varying altitudes, causing thrust efficiency to drop by up to 10-15% compared to aerospikes.

Altitude Compensation Mechanisms

Aerospike nozzles utilize altitude compensation by maintaining optimal expansion of exhaust gases across varying atmospheric pressures, allowing efficient thrust performance from sea level to vacuum without physical adjustments. The bell nozzle relies on fixed geometry optimized for a specific altitude, causing overexpansion or underexpansion losses outside its design point. Aerospike's inherent shape adapts the effective nozzle contour dynamically, mitigating altitude-induced efficiency drops common in traditional bell nozzles.

Manufacturing Complexity and Cost

Aerospike nozzles have a more complex manufacturing process due to their continuous contour design and cooling requirements, which significantly increases production time and cost compared to traditional bell nozzles. Bell nozzles benefit from simpler, well-established fabrication techniques like casting and welding, resulting in lower manufacturing complexity and reduced expenses. The higher precision and specialized materials required for aerospike nozzles drive costs upward, making them less economically viable for many applications.

Performance in Atmospheric and Vacuum Conditions

Aerospike nozzles maintain optimal performance across varying atmospheric pressures by adjusting exhaust expansion, resulting in higher efficiency both at sea level and in vacuum. Bell nozzles, optimized for either sea-level or vacuum conditions, experience efficiency losses when operating outside their design altitude due to flow separation or under-expansion. Consequently, aerospike engines provide superior thrust-to-weight ratios and specific impulse in multi-altitude missions compared to traditional bell nozzle engines.

Historical Applications and Flight Tests

Aerospike nozzles demonstrated unique efficiency in varied altitude conditions during experimental flight tests such as NASA's X-33 and the Rocketdyne linear aerospike engine, contrasting with the traditional bell nozzle's widespread use in rockets like the Space Shuttle's RS-25 engines since the 1970s. Historical applications of bell nozzles dominate spaceflight propulsion due to their simplicity and proven reliability, while aerospike nozzles, despite their theoretical altitude compensation benefits, have been primarily confined to research and prototype vehicles. Flight tests revealed challenges for aerospikes, including cooling complexities and manufacturing costs, limiting their adoption compared to the well-established bell nozzle designs in operational missions.

Challenges and Limitations of Each Design

Aerospike nozzles face challenges such as thermal management difficulties due to their exposed spike structure and complexity in manufacturing that limits widespread adoption. Bell nozzles, while simpler and well-understood, suffer from efficiency losses at off-design conditions and increased weight from structural requirements. Both designs require trade-offs between performance optimization across varying altitudes and engineering feasibility.

Future Prospects in Aerospace Propulsion

Aerospike nozzles offer superior altitude compensation compared to traditional bell nozzles, enabling enhanced efficiency across a wider range of atmospheric conditions. Their modular design and adaptability to various engine sizes position them as strong candidates for next-generation reusable launch vehicles and deep-space missions. Advances in additive manufacturing and thermal management are expected to overcome current challenges, accelerating aerospike nozzle adoption in future aerospace propulsion systems.

Expansion Ratio

Aerospike nozzles maintain near-optimal expansion ratios across a wide range of altitudes, unlike bell nozzles, which have fixed expansion ratios optimized for specific atmospheric conditions.

Thrust Efficiency

Aerospike nozzles maintain higher thrust efficiency across a wide range of altitudes by minimizing overexpansion and underexpansion losses compared to traditional bell nozzles.

Flow Separation

Aerospike nozzles maintain optimal thrust with minimal flow separation across varying altitudes, unlike bell nozzles that often suffer significant flow separation at off-design conditions.

Altitude Compensation

Aerospike nozzles maintain optimal altitude compensation by adjusting exhaust flow to varying atmospheric pressures, unlike traditional bell nozzles which are optimized for a fixed altitude, resulting in reduced efficiency at off-design altitudes.

Base Drag

Aerospike nozzles significantly reduce base drag compared to bell nozzles by maintaining optimal expansion of exhaust gases over a wider range of altitudes, enhancing rocket efficiency.

Truncated Aerospike

Truncated aerospike nozzles maintain higher altitude efficiency and reduced drag compared to traditional bell nozzles by optimizing exhaust expansion through a shorter spike design, improving thrust-to-weight ratio in varying atmospheric conditions.

Nozzle Contour

Aerospike nozzles maintain optimal expansion by dynamically adjusting the exhaust flow along a truncated central spike, while bell nozzles rely on a fixed, curved contour to direct exhaust gases for thrust efficiency.

Specific Impulse (Isp)

Aerospike nozzles provide higher Specific Impulse (Isp) than traditional bell nozzles across a wider range of altitudes due to their altitude-compensating design that maintains optimal exhaust expansion.

Shock Diamond Formation

The aerospike nozzle minimizes shock diamond formation by maintaining ambient pressure equilibrium along its surface, unlike the bell nozzle where shock diamonds form due to abrupt pressure mismatches in exhaust expansion.

Plug Nozzle

The plug nozzle, a type of aerospike nozzle, offers enhanced altitude-compensating performance and improved thrust efficiency over traditional bell nozzles by maintaining optimal expansion of exhaust gases across varying atmospheric pressures.

aerospike nozzle vs bell nozzle Infographic

njnir.com

njnir.com