Plasma actuators offer rapid response times and precise flow control without moving parts, reducing maintenance and weight compared to traditional mechanical actuators. Their ability to manipulate airflow at high frequencies improves aerodynamic efficiency and reduces noise on aircraft surfaces. Mechanical actuators, while robust and well-established, often involve heavier components and slower response rates, limiting their effectiveness in dynamic flow control applications.

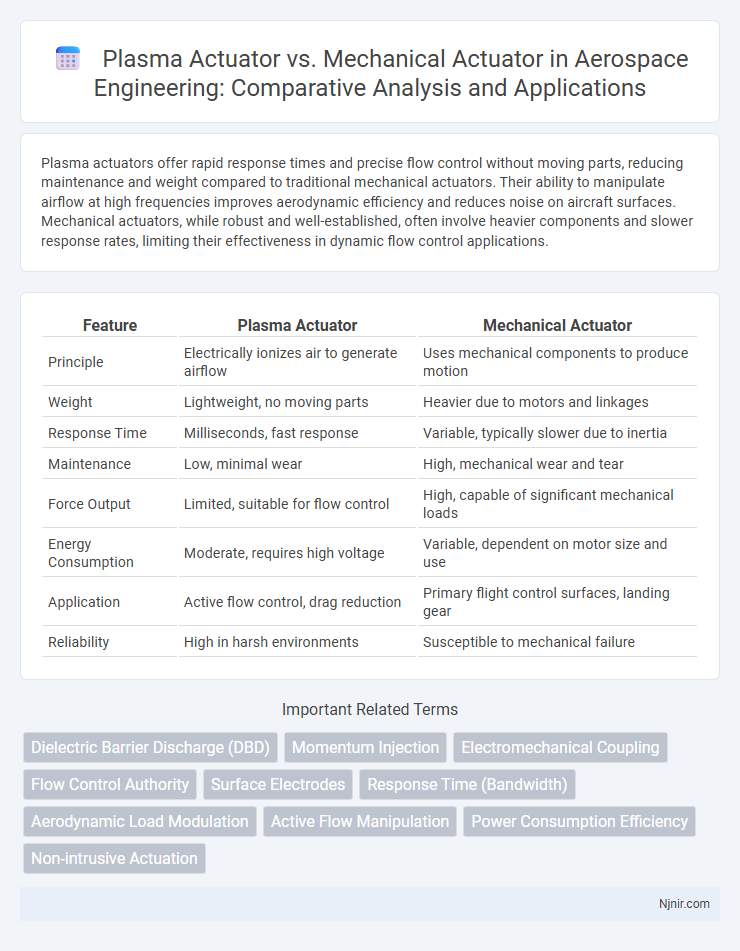

Table of Comparison

| Feature | Plasma Actuator | Mechanical Actuator |

|---|---|---|

| Principle | Electrically ionizes air to generate airflow | Uses mechanical components to produce motion |

| Weight | Lightweight, no moving parts | Heavier due to motors and linkages |

| Response Time | Milliseconds, fast response | Variable, typically slower due to inertia |

| Maintenance | Low, minimal wear | High, mechanical wear and tear |

| Force Output | Limited, suitable for flow control | High, capable of significant mechanical loads |

| Energy Consumption | Moderate, requires high voltage | Variable, dependent on motor size and use |

| Application | Active flow control, drag reduction | Primary flight control surfaces, landing gear |

| Reliability | High in harsh environments | Susceptible to mechanical failure |

Introduction to Actuators in Aerospace Engineering

Plasma actuators in aerospace engineering use ionized gas to manipulate airflow, offering rapid response times and reduced mechanical complexity compared to traditional mechanical actuators that rely on motors, gears, and linkages for control surface movement. Mechanical actuators provide high force output and reliability under extreme conditions, making them essential for primary flight controls, while plasma actuators enhance aerodynamic efficiency through flow control and drag reduction without moving parts. Integration of plasma actuators complements mechanical systems by enabling active flow manipulation, improving aircraft maneuverability and fuel efficiency.

Fundamentals of Plasma Actuators

Plasma actuators operate by generating an ionized gas layer to induce airflow through electrohydrodynamic forces, distinguishing them from mechanical actuators that rely on physical movement and mechanical linkages. The fundamental principle involves applying a high-voltage AC signal between two electrodes separated by a dielectric barrier, creating a plasma that imparts momentum to surrounding air molecules. This mechanism enables precise, rapid control of aerodynamic surfaces without moving parts, enhancing efficiency in flow control applications.

Overview of Mechanical Actuators

Mechanical actuators convert energy into physical motion through components like gears, levers, and motors, enabling precise control in various industrial applications. They rely on hydraulic, pneumatic, or electric power sources to generate force and movement, making them ideal for high-load and high-precision tasks. Unlike plasma actuators, mechanical actuators offer robust performance and durability in harsh environments, but often require more maintenance and are limited by mechanical wear.

Working Principles: Plasma vs Mechanical Actuators

Plasma actuators operate by creating an electric field that ionizes the surrounding air, generating a plasma region which induces flow through electrohydrodynamic forces without moving parts. Mechanical actuators function through physical components such as gears, pistons, or linkages that convert input energy into mechanical motion to manipulate objects or systems. The plasma actuator's reliance on ionized air contrasts with mechanical actuators' dependence on direct mechanical displacement to achieve actuation.

Efficiency and Performance Comparison

Plasma actuators offer higher efficiency in aerodynamic flow control by generating localized ionized air without mechanical parts, resulting in faster response times and reduced maintenance compared to mechanical actuators. Mechanical actuators, while providing robust and precise control through physical movement, tend to have slower response speeds and increased wear due to moving components. In performance metrics, plasma actuators excel in energy consumption and actuation frequency, whereas mechanical actuators maintain advantages in force output and reliability under high-load conditions.

Integration and Installation Challenges

Plasma actuators require high-voltage power supplies and precise electrode placement, making integration into existing aerodynamic surfaces complex compared to mechanical actuators, which rely on established mechanical linkages and actuators that are easier to install and maintain. The thin, lightweight profile of plasma actuators offers minimal aerodynamic interference but demands meticulous electrical insulation and thermal management, while mechanical actuators often result in increased weight and drag due to moving parts and structural supports. Installation of plasma actuators poses challenges related to durability under harsh environmental conditions and electromagnetic interference, whereas mechanical actuators face wear and fatigue issues but benefit from mature installation practices and robust hardware standards.

Maintenance and Reliability Aspects

Plasma actuators feature minimal moving parts, significantly reducing maintenance requirements and enhancing operational reliability compared to mechanical actuators, which involve gears, bearings, and other wear-prone components. Mechanical actuators necessitate regular lubrication, part replacement, and inspections to prevent mechanical failure, while plasma actuators primarily rely on electrical integrity and insulation quality for consistent performance. The absence of mechanical wear in plasma actuators translates to longer service intervals and lower lifecycle costs in applications demanding high reliability and minimal downtime.

Applications in Aerospace Systems

Plasma actuators offer precise flow control and reduced mechanical complexity, making them ideal for active flow management in aerospace applications like boundary layer control, drag reduction, and noise suppression on aircraft surfaces. Mechanical actuators, while more traditional and robust, provide reliable actuation for control surfaces, landing gear, and thrust vectoring under high-load conditions. Advanced aerospace systems increasingly integrate plasma actuators for their lightweight design and rapid response capabilities, complementing mechanical actuators to optimize overall system performance and fuel efficiency.

Current Research and Technological Advancements

Current research on plasma actuators centers on enhancing aerodynamic control by manipulating airflow through ionized gas, offering advantages such as reduced moving parts, faster response times, and lower maintenance compared to mechanical actuators. Technological advancements include the development of nanosecond pulsed plasma actuators, enabling more efficient flow control with minimized power consumption, and integration with adaptive control systems for real-time adjustment in aerospace applications. Mechanical actuators continue to evolve with improved materials and precision engineering, but plasma actuators represent a promising shift toward compact, lightweight, and electrically driven solutions in fluid dynamics control.

Future Trends: Plasma vs Mechanical Actuators in Aerospace

Plasma actuators offer promising advantages for future aerospace applications due to their lightweight structure, rapid response time, and lack of moving parts, which reduce maintenance and increase reliability. Mechanical actuators, while robust and well-established, face challenges in weight and mechanical wear, leading to ongoing research to integrate plasma technology for enhanced control surfaces and flow manipulation. Emerging trends focus on hybrid systems combining plasma actuators with traditional mechanical components to optimize aerodynamic efficiency and reduce fuel consumption in next-generation aircraft.

Dielectric Barrier Discharge (DBD)

Dielectric Barrier Discharge (DBD) plasma actuators generate ionized airflow without moving parts, offering faster response times and lower maintenance compared to traditional mechanical actuators reliant on physical motion.

Momentum Injection

Plasma actuators inject momentum into airflow by ionizing air to create body forces that accelerate the fluid, whereas mechanical actuators physically move surfaces or fluids to generate momentum changes.

Electromechanical Coupling

Plasma actuators exhibit superior electromechanical coupling efficiency compared to mechanical actuators by converting electrical energy directly into aerodynamic forces without mechanical moving parts.

Flow Control Authority

Plasma actuators provide superior flow control authority over mechanical actuators by enabling rapid, precise manipulation of airflow with no moving parts and lower energy consumption.

Surface Electrodes

Plasma actuators with surface electrodes offer silent, fast-response airflow control and no moving parts compared to mechanical actuators requiring complex components and maintenance.

Response Time (Bandwidth)

Plasma actuators offer significantly faster response times with bandwidths exceeding several kilohertz, outperforming mechanical actuators that typically operate within a few hundred hertz due to their inertia and physical movement constraints.

Aerodynamic Load Modulation

Plasma actuators offer rapid, low-mass aerodynamic load modulation by generating ionized flow control without moving parts, whereas mechanical actuators rely on heavier, slower-moving components to physically alter airflow and surface geometry.

Active Flow Manipulation

Plasma actuators offer precise, rapid response with no moving parts for Active Flow Manipulation, enhancing aerodynamic control more efficiently than traditional mechanical actuators.

Power Consumption Efficiency

Plasma actuators consume significantly less power than mechanical actuators, offering higher efficiency for aerodynamic flow control applications.

Non-intrusive Actuation

Plasma actuators provide non-intrusive actuation by generating body forces in airflow without moving parts, unlike mechanical actuators that require physical contact and alter fluid dynamics through mechanical motion.

plasma actuator vs mechanical actuator Infographic

njnir.com

njnir.com