Automated milking systems enhance efficiency by reducing labor costs and allowing continuous, stress-free milking which improves animal welfare and milk quality. Conventional milking methods rely heavily on manual labor and fixed schedules, often causing inconsistent milking intervals and increased labor demands. Transitioning to automated milking technology supports precision dairy farming by collecting real-time data on milk yield and animal health.

Table of Comparison

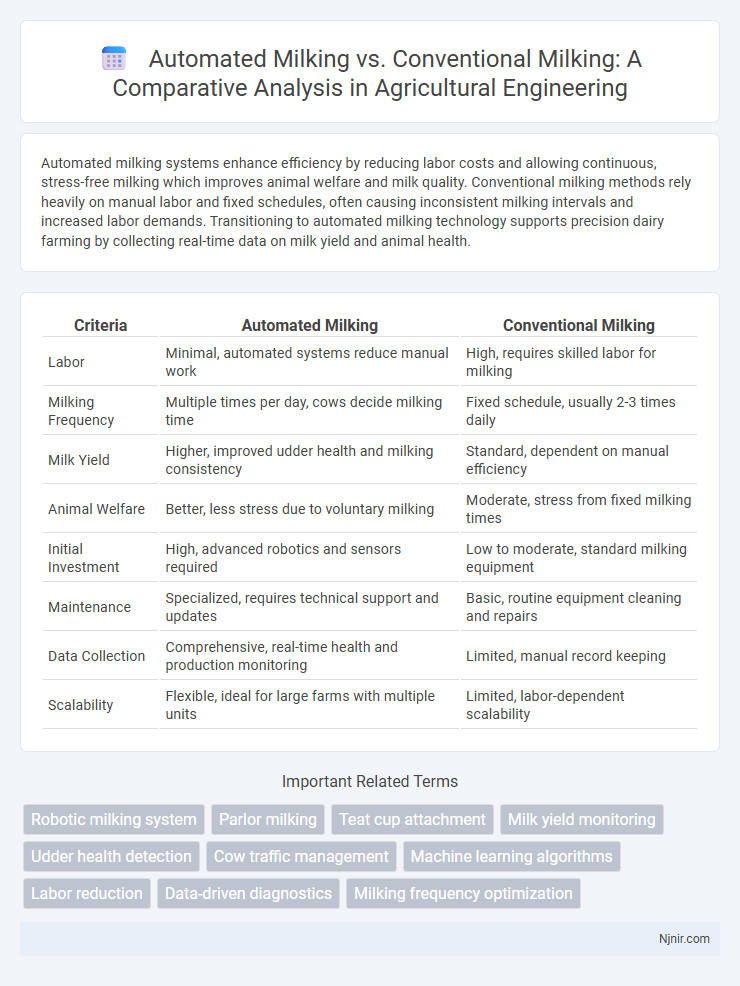

| Criteria | Automated Milking | Conventional Milking |

|---|---|---|

| Labor | Minimal, automated systems reduce manual work | High, requires skilled labor for milking |

| Milking Frequency | Multiple times per day, cows decide milking time | Fixed schedule, usually 2-3 times daily |

| Milk Yield | Higher, improved udder health and milking consistency | Standard, dependent on manual efficiency |

| Animal Welfare | Better, less stress due to voluntary milking | Moderate, stress from fixed milking times |

| Initial Investment | High, advanced robotics and sensors required | Low to moderate, standard milking equipment |

| Maintenance | Specialized, requires technical support and updates | Basic, routine equipment cleaning and repairs |

| Data Collection | Comprehensive, real-time health and production monitoring | Limited, manual record keeping |

| Scalability | Flexible, ideal for large farms with multiple units | Limited, labor-dependent scalability |

Introduction to Milking Systems in Modern Dairy Farming

Automated milking systems (AMS) utilize robotics and sensor technology to enhance efficiency and animal welfare by allowing cows to be milked voluntarily, reducing labor costs and improving milk consistency. Conventional milking relies on manual or semi-automated equipment operated by farm workers, which can increase labor demands and stress on animals due to fixed milking schedules. Modern dairy farming increasingly adopts AMS for precise monitoring of cow health and production metrics, optimizing overall herd management.

Overview of Conventional Milking Techniques

Conventional milking techniques rely on manual or machine-assisted methods where a farmer or worker manually attaches milking units to the cows, typically using bucket or pipeline milking systems. These methods involve scheduled milking times and require significant labor input, often impacting farm efficiency and labor costs. Despite being labor-intensive, conventional milking remains prevalent due to its lower initial investment compared to automated systems.

Evolution and Adoption of Automated Milking Systems

Automated milking systems (AMS) have evolved significantly since their inception in the early 1990s, driven by advancements in robotics, sensor technology, and data analytics, which optimize milking efficiency and animal welfare. Adoption rates of AMS have surged globally, especially in Europe and North America, where farms report increased labor savings, improved milk quality, and enhanced herd management through real-time monitoring. Despite higher initial investments, the scalability and precision of automated systems are transforming traditional dairy farming practices, supporting sustainable production and addressing labor shortages.

Labor Efficiency: Manual vs Automated Milking

Automated milking systems enhance labor efficiency by reducing the need for manual labor, allowing a single operator to manage multiple cows simultaneously compared to conventional milking which requires more hands-on time. These systems utilize robotic arms and sensors to perform milking tasks precisely and consistently, minimizing labor-intensive routines such as teat cleaning and attachment. Consequently, automated milking decreases labor costs and physical strain, improving overall productivity on dairy farms.

Animal Health and Welfare: Comparative Analysis

Automated milking systems (AMS) enhance animal health by providing consistent milking intervals, reducing stress and the risk of mastitis compared to conventional milking methods. Continuous monitoring through AMS enables early detection of health issues, improving overall welfare and enabling proactive management. In contrast, conventional milking can introduce variable stress levels due to manual handling and fixed schedules, potentially impacting udder health and animal comfort.

Milk Yield and Quality: Technology Impact

Automated milking systems (AMS) significantly enhance milk yield by enabling more frequent and consistent milking sessions, which reduces animal stress and improves udder health. Studies show that AMS maintain or improve milk quality parameters such as somatic cell count and bacterial contamination compared to conventional milking methods, due to precise teat cleaning and controlled milking environments. The integration of sensor technology in automated systems allows real-time monitoring and adjustments, optimizing milk composition and ensuring high-quality dairy production.

Economic Considerations and Cost-Benefit Analysis

Automated milking systems (AMS) require higher initial capital investment, often exceeding $150,000 per unit, compared to conventional milking setups that typically cost less than $50,000. Economic considerations include labor savings, with AMS reducing labor costs by up to 60%, while increasing milk yield by 5-15% due to improved milking frequency and cow comfort. Cost-benefit analysis reveals that farms with over 100 cows achieve return on investment within 3-5 years through enhanced productivity and lower labor expenses, whereas smaller farms may find conventional milking more economically viable.

Technological Integration and Data Management

Automated milking systems leverage advanced robotic technology and sensor integration to enhance precision and efficiency, collecting real-time data on milk yield, cow health, and behavior. Conventional milking relies on manual labor with limited data capture, restricting detailed monitoring and timely decision-making. The rich datasets generated by automated systems enable predictive analytics and customized herd management, significantly improving productivity and animal welfare.

Environmental Sustainability and Resource Usage

Automated milking systems reduce water and energy consumption by precisely managing the milking process and minimizing waste, which enhances environmental sustainability compared to conventional milking. These systems optimize feed efficiency and reduce greenhouse gas emissions through improved herd monitoring and health management. Conventional milking typically requires higher labor inputs and generates more waste, contributing to greater resource use and environmental impact.

Future Trends in Dairy Milking Technologies

Automated milking systems, driven by advancements in robotics, artificial intelligence, and sensor technologies, are poised to transform dairy farming by enhancing milk yield, animal welfare, and labor efficiency compared to conventional milking. Future trends emphasize integration with Internet of Things (IoT) platforms, enabling real-time health monitoring, predictive maintenance, and data analytics to optimize farm management. Sustainable and precision farming practices will further leverage automated milking innovations to reduce environmental impact and improve overall productivity in dairy operations.

Robotic milking system

Robotic milking systems increase dairy farm efficiency by enabling automated, stress-free milking that improves milk yield, animal health monitoring, and labor cost reduction compared to conventional milking methods.

Parlor milking

Automated milking systems significantly increase efficiency and cow comfort in parlor milking compared to conventional milking by reducing labor costs and improving milking consistency.

Teat cup attachment

Automated milking systems enhance teat cup attachment precision and consistency compared to conventional milking, reducing teat injury and improving milking efficiency.

Milk yield monitoring

Automated milking systems provide continuous, real-time milk yield monitoring, enabling precise data collection and improved herd management compared to conventional milking methods that rely on periodic manual measurements.

Udder health detection

Automated milking systems enhance udder health detection by continuously monitoring somatic cell counts and milk conductivity, enabling early identification of mastitis compared to conventional milking methods.

Cow traffic management

Automated milking systems enhance cow traffic management by using sensor-guided pathways and voluntary cow movement, increasing milking efficiency and animal welfare compared to conventional milking methods that rely on scheduled manual herding.

Machine learning algorithms

Machine learning algorithms enhance automated milking systems by optimizing cow health monitoring, milking efficiency, and yield prediction compared to conventional milking methods.

Labor reduction

Automated milking systems reduce labor requirements by up to 60% compared to conventional milking methods, increasing efficiency and lowering operational costs.

Data-driven diagnostics

Automated milking systems leverage real-time data analytics and sensor technology to enable precise, data-driven diagnostics that improve herd health and milk production efficiency compared to conventional milking methods.

Milking frequency optimization

Automated milking systems optimize milking frequency by enabling cows to be milked multiple times daily based on individual needs, enhancing milk yield and udder health compared to the fixed schedules of conventional milking.

Automated milking vs Conventional milking Infographic

njnir.com

njnir.com