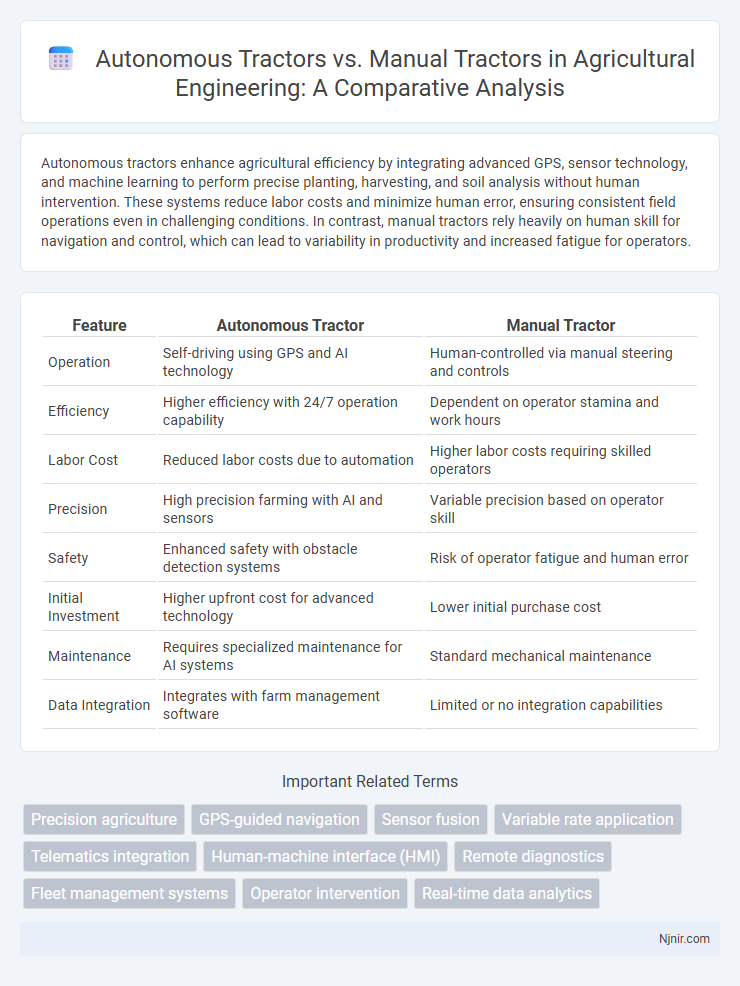

Autonomous tractors enhance agricultural efficiency by integrating advanced GPS, sensor technology, and machine learning to perform precise planting, harvesting, and soil analysis without human intervention. These systems reduce labor costs and minimize human error, ensuring consistent field operations even in challenging conditions. In contrast, manual tractors rely heavily on human skill for navigation and control, which can lead to variability in productivity and increased fatigue for operators.

Table of Comparison

| Feature | Autonomous Tractor | Manual Tractor |

|---|---|---|

| Operation | Self-driving using GPS and AI technology | Human-controlled via manual steering and controls |

| Efficiency | Higher efficiency with 24/7 operation capability | Dependent on operator stamina and work hours |

| Labor Cost | Reduced labor costs due to automation | Higher labor costs requiring skilled operators |

| Precision | High precision farming with AI and sensors | Variable precision based on operator skill |

| Safety | Enhanced safety with obstacle detection systems | Risk of operator fatigue and human error |

| Initial Investment | Higher upfront cost for advanced technology | Lower initial purchase cost |

| Maintenance | Requires specialized maintenance for AI systems | Standard mechanical maintenance |

| Data Integration | Integrates with farm management software | Limited or no integration capabilities |

Overview of Autonomous and Manual Tractors

Autonomous tractors utilize advanced GPS, sensors, and AI technology to operate without human intervention, enhancing precision in farming tasks such as planting and harvesting. Manual tractors rely on human operators for control and decision-making, offering flexibility but requiring continuous labor input and skill. The integration of autonomous capabilities reduces human error and boosts efficiency, while manual tractors provide adaptability in varied field conditions.

Key Technological Differences

Autonomous tractors integrate advanced GPS, machine learning algorithms, and sensor technologies to enable precise navigation and real-time decision-making without human intervention, contrasting with manual tractors that rely on operator control for steering and task execution. Key technological differences include the use of LiDAR and computer vision in autonomous tractors for obstacle detection, whereas manual tractors depend solely on operator awareness for safety and maneuvering. Autonomous systems also leverage data analytics for optimized field patterns and efficiency, a capability absent in traditional manual tractor operations.

Efficiency and Productivity Comparison

Autonomous tractors significantly enhance efficiency by integrating GPS technology and AI-driven path optimization, reducing fuel consumption by up to 20% compared to manual tractors. Productivity increases as autonomous tractors operate continuously without fatigue, covering larger acreage in less time and minimizing downtime associated with human labor constraints. Manual tractors, while effective, rely heavily on operator skill and endurance, leading to variability in performance and higher labor costs over extended periods.

Cost Analysis: Initial Investment and Maintenance

Autonomous tractors require a higher initial investment, often ranging from $200,000 to $400,000, compared to manual tractors costing between $50,000 and $150,000. Maintenance costs for autonomous tractors can be lower due to precision technology reducing wear and fuel consumption, but specialized parts and software updates may increase expenses. Over time, autonomous tractors may offer cost savings through improved efficiency and reduced labor costs despite the upfront financial commitment.

Labor Requirements and Workforce Impacts

Autonomous tractors significantly reduce labor requirements by minimizing the need for skilled operators, allowing a single worker to oversee multiple machines remotely. This shift leads to workforce impacts such as job displacement for traditional tractor operators but also creates demand for new roles in technology management, maintenance, and data analysis. The overall effect on labor markets depends on the rate of adoption and the agricultural sector's ability to retrain workers for advanced technical positions.

Precision and Accuracy in Field Operations

Autonomous tractors utilize advanced GPS and sensor technologies to achieve higher precision and accuracy in field operations compared to manual tractors, enabling consistent planting spacing and optimal fertilizer application. Manual tractors rely heavily on operator skill, resulting in greater variability and potential for human error in tasks such as seed placement and weed control. Enhanced precision of autonomous tractors leads to improved crop yields and resource efficiency by minimizing overlaps and gaps during fieldwork.

Safety Features and Risk Management

Autonomous tractors are equipped with advanced safety features such as GPS-guided navigation, obstacle detection sensors, and emergency shutdown systems that significantly reduce the risk of human error and accidents in agricultural operations. Manual tractors rely heavily on operator vigilance and training to manage hazards, which increases the potential for injuries due to fatigue, misjudgment, or limited situational awareness. Risk management in autonomous tractors involves continuous software updates and real-time monitoring, enhancing predictive maintenance and minimizing downtime compared to traditional manual systems.

Environmental Impact and Sustainability

Autonomous tractors optimize fuel efficiency and reduce soil compaction by using precise GPS-guided paths, leading to lower greenhouse gas emissions compared to manual tractors. Their ability to perform tasks with minimal overlap and optimized timing enhances sustainable land management and conserves resources like fuel and water. Manual tractors rely heavily on operator skill, often resulting in increased fuel consumption and greater environmental degradation due to inconsistent field coverage and soil disruption.

Challenges in Adoption and Implementation

Autonomous tractors face significant challenges in adoption due to high initial costs, complex technology integration, and the need for reliable GPS and sensor systems. Manual tractors, though more accessible and widely used, require skilled operators and have limitations in efficiency and precision compared to autonomous models. Farmers must also address concerns related to data security, maintenance of autonomous systems, and regulatory compliance during implementation.

Future Trends in Tractor Technology

Autonomous tractors are rapidly advancing with AI-powered navigation systems and precision farming technologies, promising increased efficiency and reduced labor costs compared to manual tractors. Integration of IoT sensors and real-time data analytics enables autonomous tractors to optimize fuel usage and crop management, driving sustainable agriculture practices. Future trends include enhanced machine learning algorithms and improved connectivity, which will enable seamless coordination between multiple autonomous units in large-scale farming operations.

Precision agriculture

Autonomous tractors enhance precision agriculture by using GPS-guided technology and real-time data analytics to optimize planting, reduce overlaps, and minimize resource waste compared to manual tractors.

GPS-guided navigation

Autonomous tractors utilize GPS-guided navigation to precisely optimize fieldwork efficiency and reduce human error, outperforming manual tractors that rely on operator skill for navigation accuracy.

Sensor fusion

Autonomous tractors leverage advanced sensor fusion technologies combining LiDAR, GPS, cameras, and radar to enhance precision and operational efficiency compared to manual tractors that rely solely on human input.

Variable rate application

Autonomous tractors enhance variable rate application precision by using real-time data and GPS technology to optimize input delivery, reducing waste and increasing crop yield compared to manual tractors.

Telematics integration

Autonomous tractors equipped with advanced telematics integration enable real-time data monitoring, precise GPS navigation, and remote diagnostics, significantly outperforming manual tractors in operational efficiency and maintenance management.

Human-machine interface (HMI)

Autonomous tractors feature advanced Human-Machine Interface (HMI) systems with intuitive touchscreen controls and real-time data feedback, enhancing operator efficiency and reducing manual input compared to traditional manual tractors.

Remote diagnostics

Autonomous tractors equipped with advanced remote diagnostics enable real-time monitoring and predictive maintenance, significantly reducing downtime compared to manual tractors.

Fleet management systems

Autonomous tractors equipped with advanced fleet management systems optimize agricultural efficiency by enabling real-time monitoring, precise scheduling, and data-driven decision-making compared to manual tractors.

Operator intervention

Autonomous tractors require minimal operator intervention by using advanced sensors and GPS technology, whereas manual tractors depend entirely on continuous operator control and input.

Real-time data analytics

Autonomous tractors leverage real-time data analytics to optimize field operations with increased precision and efficiency compared to manual tractors.

Autonomous tractor vs Manual tractor Infographic

njnir.com

njnir.com