Plant-based plastics offer a sustainable alternative to petroleum-based plastics by reducing reliance on fossil fuels and decreasing carbon emissions. These bioplastics are biodegradable and derived from renewable resources such as corn, sugarcane, and cellulose, enhancing environmental compatibility. However, challenges remain in scalability, cost, and performance compared to traditional plastics in agricultural applications.

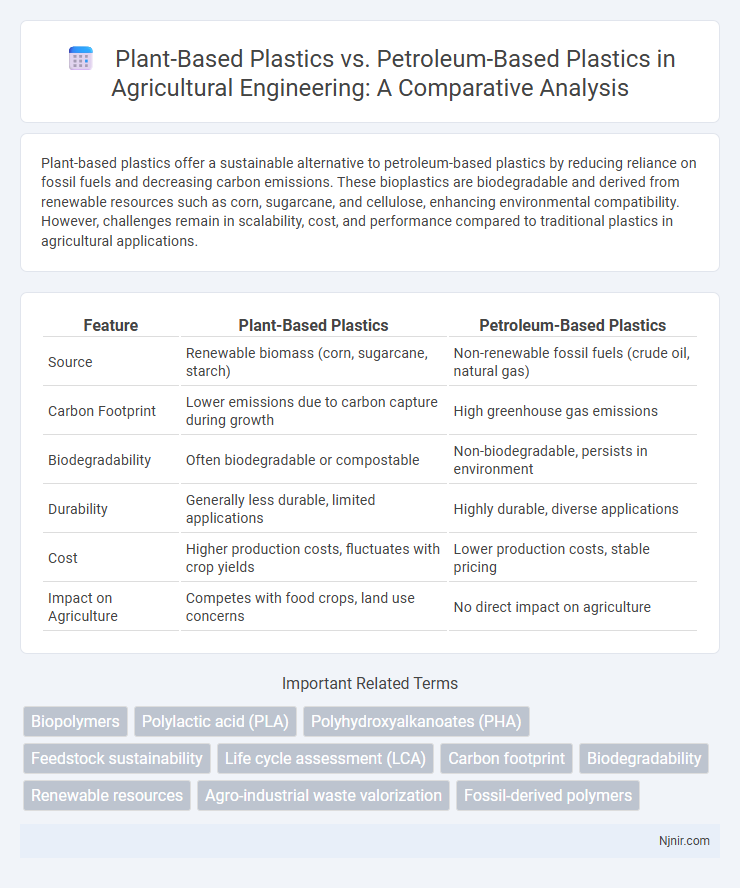

Table of Comparison

| Feature | Plant-Based Plastics | Petroleum-Based Plastics |

|---|---|---|

| Source | Renewable biomass (corn, sugarcane, starch) | Non-renewable fossil fuels (crude oil, natural gas) |

| Carbon Footprint | Lower emissions due to carbon capture during growth | High greenhouse gas emissions |

| Biodegradability | Often biodegradable or compostable | Non-biodegradable, persists in environment |

| Durability | Generally less durable, limited applications | Highly durable, diverse applications |

| Cost | Higher production costs, fluctuates with crop yields | Lower production costs, stable pricing |

| Impact on Agriculture | Competes with food crops, land use concerns | No direct impact on agriculture |

Introduction to Plastics in Agriculture

Plant-based plastics in agriculture offer biodegradable and renewable alternatives to traditional petroleum-based plastics, reducing environmental impact and soil contamination. Petroleum-based plastics, widely used for mulch films and greenhouse covers, contribute to persistent plastic pollution due to their non-degradable nature. Innovations in bio-based polymers such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA) enhance sustainability by promoting soil health and lowering carbon footprint in agricultural applications.

Overview of Plant-Based Plastics

Plant-based plastics, derived from renewable biomass sources such as corn, sugarcane, and potato starch, offer a sustainable alternative to traditional petroleum-based plastics. These bioplastics, including polylactic acid (PLA) and polyhydroxyalkanoates (PHA), exhibit biodegradability and lower carbon footprints during production. Innovations in plant-based polymers contribute significantly to reducing environmental pollution and dependence on fossil fuels.

Petroleum-Based Plastics: Characteristics and Use

Petroleum-based plastics, derived primarily from fossil fuels such as crude oil and natural gas, possess characteristics like durability, flexibility, and cost-effectiveness, making them suitable for a wide range of applications including packaging, automotive parts, and household items. Their industrial production relies on polymerization processes that produce materials such as polyethylene, polypropylene, and polystyrene, known for their high tensile strength and resistance to heat and chemicals. Despite their versatility and widespread use, petroleum-based plastics contribute significantly to environmental pollution and carbon emissions due to their non-biodegradable nature and dependence on finite fossil resources.

Environmental Impact: Biodegradability and Pollution

Plant-based plastics, derived from renewable biomass like corn or sugarcane, exhibit enhanced biodegradability compared to petroleum-based plastics, which are primarily composed of long-lasting synthetic polymers. Biodegradable plant-based plastics reduce landfill accumulation and lower microplastic pollution in oceans due to their ability to decompose under specific conditions, thereby mitigating environmental damage. Conversely, petroleum-based plastics contribute significantly to persistent pollution and greenhouse gas emissions throughout their lifecycle, exacerbating global waste management challenges and climate change.

Resource Sustainability and Raw Material Sourcing

Plant-based plastics utilize renewable resources such as corn, sugarcane, and cellulose, reducing reliance on finite fossil fuels and decreasing carbon footprints. Petroleum-based plastics depend on non-renewable crude oil extraction, contributing to environmental degradation and resource depletion. Sustainable raw material sourcing for plant-based plastics supports circular economy principles by enabling biodegradability and lower greenhouse gas emissions compared to traditional plastics.

Performance and Durability in Agricultural Applications

Plant-based plastics in agricultural applications exhibit improved biodegradability but often fall short in performance and durability compared to petroleum-based plastics, which provide superior strength, UV resistance, and moisture barrier properties essential for crop protection and soil health. The tensile strength and lifespan of petroleum-based plastics typically exceed those of plant-based alternatives, making them more reliable for long-term use in harsh environmental conditions. Innovations in biopolymers aim to bridge this gap by enhancing mechanical properties and weather resistance to meet the rigorous demands of agricultural practices.

Economic Considerations: Cost and Scalability

Plant-based plastics generally have higher production costs due to raw material expenses and limited large-scale manufacturing infrastructure compared to petroleum-based plastics, which benefit from established supply chains and economies of scale. The scalability of plant-based plastics is constrained by agricultural resource availability and competition with food production, while petroleum-based plastics maintain consistent output through mature refining technologies. Market fluctuations in oil prices significantly impact petroleum-based plastic costs, whereas plant-based plastics are influenced by crop yields and bioresource price volatility.

Technological Challenges and Innovations

Plant-based plastics face technological challenges such as limited durability, higher production costs, and difficulties in large-scale manufacturing compared to petroleum-based plastics. Innovations in bioengineering and polymer science are improving the mechanical properties and biodegradability of bioplastics, enhancing their competitiveness. Advanced enzymatic processing and catalytic conversion technologies are enabling more efficient and sustainable production methods for plant-based plastics.

Regulatory Frameworks and Certification Standards

Regulatory frameworks for plant-based plastics emphasize biodegradability and compostability standards, such as ASTM D6400 and EN 13432 certifications, to ensure environmental compliance and promote sustainable waste management. Petroleum-based plastics face stricter regulations targeting carbon emissions, chemical additives, and recycling mandates under policies like the European Union's Single-Use Plastics Directive and the U.S. EPA's Plastic Waste Reduction initiatives. Certification bodies including BPI (Biodegradable Products Institute) and TUV Austria provide verification for compostable bioplastics, distinguishing them from conventional petroleum-derived polymers in global markets.

Future Perspectives in Sustainable Agricultural Plastics

Plant-based plastics, derived from renewable biomass such as corn starch and sugarcane, offer promising future perspectives in sustainable agricultural plastics by reducing dependence on fossil fuels and lowering greenhouse gas emissions. Innovations in biodegradable plant-based polymers can enhance soil health by minimizing plastic residue accumulation, promoting an eco-friendly alternative to petroleum-based plastics that persist in the environment. Advancements in enzymatic degradation and composite materials are driving the evolution of plant-based agricultural plastics to match the durability and cost-effectiveness of conventional petroleum counterparts.

Biopolymers

Biopolymers derived from plant-based plastics offer biodegradable and renewable alternatives to petroleum-based plastics, reducing environmental impact and dependence on fossil fuels.

Polylactic acid (PLA)

Polylactic acid (PLA), a biodegradable plant-based plastic derived from renewable resources like corn starch, offers a sustainable alternative to petroleum-based plastics by reducing carbon emissions and enhancing compostability in packaging applications.

Polyhydroxyalkanoates (PHA)

Polyhydroxyalkanoates (PHA), derived from renewable plant-based sources, offer a biodegradable and eco-friendly alternative to petroleum-based plastics, significantly reducing environmental pollution and reliance on fossil fuels.

Feedstock sustainability

Plant-based plastics utilize renewable feedstocks like corn and sugarcane, promoting sustainable resource cycles compared to the finite fossil fuels required for petroleum-based plastics.

Life cycle assessment (LCA)

Life cycle assessment (LCA) reveals that plant-based plastics typically generate lower carbon emissions and reduced environmental impact compared to petroleum-based plastics, although factors such as land use and agricultural inputs influence overall sustainability.

Carbon footprint

Plant-based plastics generally have a lower carbon footprint than petroleum-based plastics due to their renewable raw materials and reduced greenhouse gas emissions during production.

Biodegradability

Plant-based plastics exhibit superior biodegradability compared to petroleum-based plastics, breaking down more rapidly in natural environments and reducing long-term pollution.

Renewable resources

Plant-based plastics are derived from renewable resources like corn and sugarcane, significantly reducing reliance on finite petroleum-based plastics.

Agro-industrial waste valorization

Agro-industrial waste valorization drives the development of sustainable plant-based plastics by converting biomass residues into biodegradable polymers, reducing reliance on petroleum-based plastics and minimizing environmental impact.

Fossil-derived polymers

Fossil-derived polymers in petroleum-based plastics contribute significantly to environmental pollution due to their non-biodegradable nature and reliance on finite fossil fuel resources.

Plant-based plastics vs petroleum-based plastics Infographic

njnir.com

njnir.com