UAV spraying offers precise application of pesticides and fertilizers, reducing chemical waste and environmental impact compared to manual spraying. It enhances efficiency by covering large areas quickly and accessing difficult terrains, which is often challenging for manual labor. Advanced UAV technologies also allow real-time monitoring and data-driven adjustments, improving crop health management beyond traditional methods.

Table of Comparison

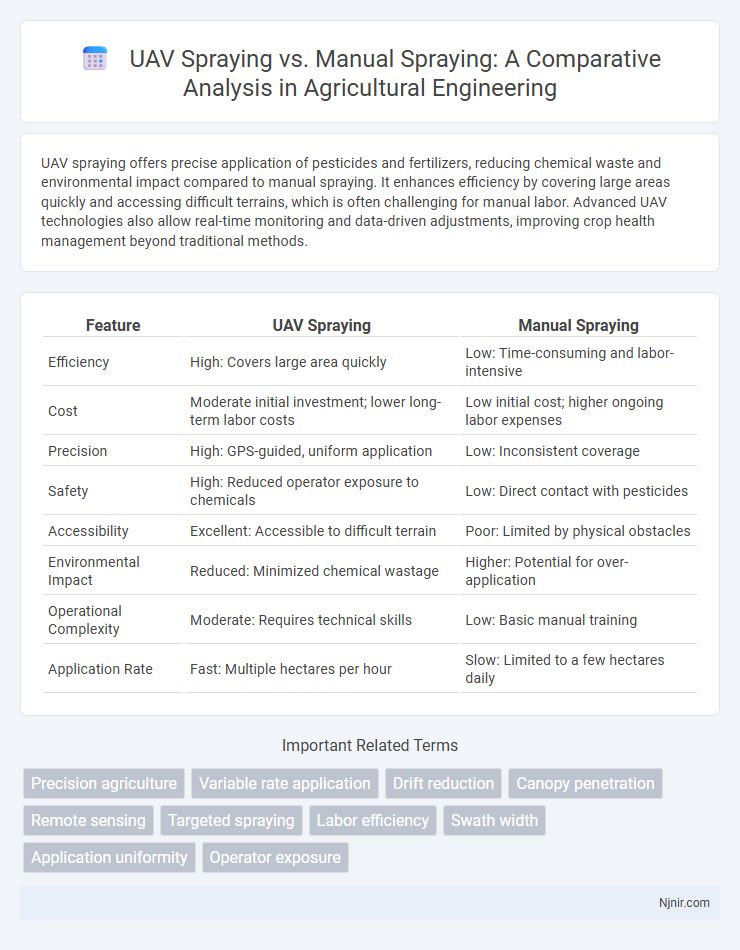

| Feature | UAV Spraying | Manual Spraying |

|---|---|---|

| Efficiency | High: Covers large area quickly | Low: Time-consuming and labor-intensive |

| Cost | Moderate initial investment; lower long-term labor costs | Low initial cost; higher ongoing labor expenses |

| Precision | High: GPS-guided, uniform application | Low: Inconsistent coverage |

| Safety | High: Reduced operator exposure to chemicals | Low: Direct contact with pesticides |

| Accessibility | Excellent: Accessible to difficult terrain | Poor: Limited by physical obstacles |

| Environmental Impact | Reduced: Minimized chemical wastage | Higher: Potential for over-application |

| Operational Complexity | Moderate: Requires technical skills | Low: Basic manual training |

| Application Rate | Fast: Multiple hectares per hour | Slow: Limited to a few hectares daily |

Introduction to UAV and Manual Spraying Methods

UAV spraying involves the use of unmanned aerial vehicles equipped with precision spraying technology to apply pesticides and fertilizers efficiently over large agricultural areas, minimizing human exposure and reducing chemical waste. Manual spraying methods rely on human operators using handheld or backpack sprayers, which can be labor-intensive, time-consuming, and often result in uneven coverage and increased risk of chemical exposure. Advances in UAV technology allow for optimized spray patterns and real-time monitoring, enhancing crop health management compared to traditional manual approaches.

Technology Overview: UAV Spraying Systems

UAV spraying systems leverage advanced drone technology equipped with precision nozzles, GPS-guided flight paths, and real-time monitoring sensors to optimize agricultural pesticide application. These systems enable uniform chemical distribution, reduce human exposure to harmful substances, and improve coverage efficiency compared to manual spraying. Integration of AI and machine learning algorithms further enhances decision-making by analyzing crop health data for targeted spraying interventions.

Manual Spraying Techniques and Tools

Manual spraying techniques rely heavily on handheld or backpack sprayers equipped with adjustable nozzles to deliver pesticides or fertilizers directly onto crops, allowing precise application in small or unevenly shaped fields. Proper calibration of spraying pressure and droplet size is essential to maximize coverage while minimizing drift and chemical waste. Skilled operators use systematic walking patterns and maintain consistent spraying speeds to ensure uniform distribution and effective pest control.

Comparative Cost Analysis: UAV vs Manual Spraying

UAV spraying significantly reduces labor costs compared to manual spraying, as drones require fewer operators and less time to cover large agricultural areas. Initial investment in UAV technology can be higher, but lower operational expenses and increased efficiency often lead to a lower total cost per hectare in the long run. Studies indicate that UAV spraying can cut pesticide usage by up to 30%, further decreasing material costs compared to traditional manual methods.

Efficiency and Coverage Rates

UAV spraying offers significantly higher efficiency and coverage rates compared to manual spraying, enabling rapid treatment of large agricultural fields with precise application. UAVs can cover up to 10 hectares per hour, reducing labor costs and minimizing pesticide wastage due to their targeted and consistent spraying patterns. In contrast, manual spraying's limited reach and slower pace often result in uneven coverage and increased operator fatigue.

Precision and Accuracy in Chemical Application

UAV spraying offers enhanced precision in chemical application by utilizing GPS-guided flight paths and variable rate technology, ensuring chemicals are distributed evenly and only where needed. The controlled altitude and speed of drones minimize chemical drift and overlap, leading to higher accuracy compared to manual spraying methods. Manual spraying often results in uneven coverage and higher variability due to human error and environmental factors, reducing overall application efficacy.

Environmental Impact Assessment

UAV spraying significantly reduces environmental contamination by minimizing pesticide drift and ensuring precise application, lowering the risk of soil and water pollution compared to manual spraying. The targeted approach of UAVs decreases chemical usage, promoting sustainable agricultural practices and reducing harm to non-target organisms and biodiversity. Manual spraying often leads to higher chemical runoff and exposure, increasing negative impacts on surrounding ecosystems and human health.

Labor and Safety Considerations

UAV spraying significantly reduces labor requirements by automating the application process, minimizing the need for manual handling and physical exertion typically involved in manual spraying. The use of drones enhances safety by limiting worker exposure to harmful chemicals and reducing the risk of accidents associated with traditional sprayers, such as falls or inhalation hazards. This technological shift also allows operators to maintain a safe distance from treated areas, promoting better health outcomes and operational efficiency in agricultural practices.

Challenges and Limitations in Field Adoption

UAV spraying faces challenges such as high initial costs, limited payload capacity, and regulatory restrictions that hinder widespread field adoption compared to manual spraying. Manual spraying offers greater flexibility in complex terrains and crop types but suffers from labor intensity and slower application rates. Both methods encounter limitations in weather dependency and precision, affecting overall efficiency and scalability.

Future Trends in Agricultural Spraying Technologies

UAV spraying is set to revolutionize agricultural spraying technologies by offering precision application, reducing chemical waste, and minimizing environmental impact compared to manual spraying. Advanced UAV systems integrate AI and GPS for real-time monitoring and optimized spray patterns, enhancing crop health and yield efficiency. Future trends emphasize autonomous operations, data-driven decision-making, and sustainable practices that surpass the capabilities of traditional manual spraying methods.

Precision agriculture

UAV spraying enhances precision agriculture by delivering targeted, efficient pesticide application that reduces chemical use and environmental impact compared to manual spraying.

Variable rate application

UAV spraying enables precise variable rate application by using GPS and sensor data to adjust pesticide amounts in real-time, significantly enhancing efficiency and reducing chemical waste compared to manual spraying.

Drift reduction

UAV spraying reduces drift by enabling precise, targeted application with controlled droplet size and low-release altitude compared to manual spraying.

Canopy penetration

UAV spraying achieves superior canopy penetration compared to manual spraying by delivering pesticides more uniformly and efficiently within dense foliage.

Remote sensing

UAV spraying enhances precision agriculture by integrating advanced remote sensing technologies to optimize pesticide application, reduce environmental impact, and improve crop health monitoring compared to manual spraying.

Targeted spraying

UAV spraying delivers precise, targeted pesticide application, reducing chemical usage and minimizing environmental impact compared to manual spraying.

Labor efficiency

UAV spraying increases labor efficiency by covering larger areas faster and reducing the need for manual labor compared to traditional manual spraying methods.

Swath width

UAV spraying achieves a swath width of up to 20 meters, significantly surpassing the typical 1-3 meter swath width of manual spraying, enhancing coverage efficiency and reducing labor time.

Application uniformity

UAV spraying achieves superior application uniformity compared to manual spraying by delivering precise, consistent coverage with reduced human error and optimized droplet distribution.

Operator exposure

UAV spraying significantly reduces operator exposure to harmful chemicals compared to manual spraying by minimizing direct contact and inhalation risks during pesticide application.

UAV spraying vs manual spraying Infographic

njnir.com

njnir.com