CAN bus offers higher data rates and robust error handling, making it ideal for complex automotive networks requiring real-time communication. LIN bus serves as a cost-effective, lower-speed alternative designed for simpler subsystems with less stringent timing requirements. Selecting between CAN and LIN buses depends on the specific demands of data throughput, network complexity, and system reliability within the vehicle's electronic architecture.

Table of Comparison

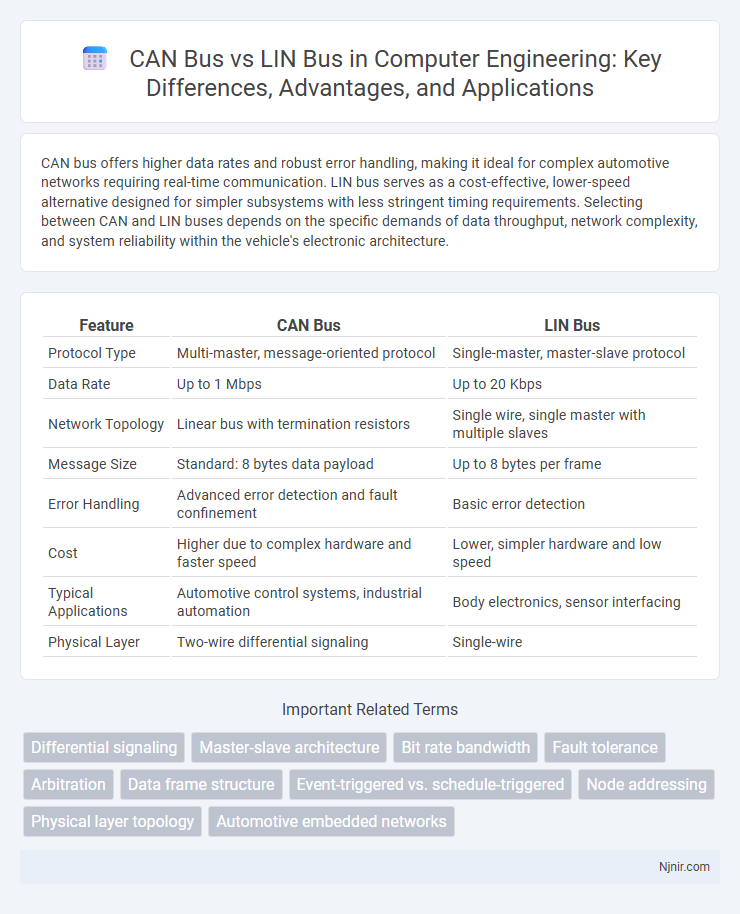

| Feature | CAN Bus | LIN Bus |

|---|---|---|

| Protocol Type | Multi-master, message-oriented protocol | Single-master, master-slave protocol |

| Data Rate | Up to 1 Mbps | Up to 20 Kbps |

| Network Topology | Linear bus with termination resistors | Single wire, single master with multiple slaves |

| Message Size | Standard: 8 bytes data payload | Up to 8 bytes per frame |

| Error Handling | Advanced error detection and fault confinement | Basic error detection |

| Cost | Higher due to complex hardware and faster speed | Lower, simpler hardware and low speed |

| Typical Applications | Automotive control systems, industrial automation | Body electronics, sensor interfacing |

| Physical Layer | Two-wire differential signaling | Single-wire |

Introduction to CAN Bus and LIN Bus

CAN bus (Controller Area Network) is a robust vehicle bus standard designed for real-time communication between microcontrollers and devices without a host computer, widely used in automotive and industrial applications for high-speed data exchange. LIN bus (Local Interconnect Network) serves as a lower-cost, lower-speed communication protocol primarily for simpler devices and subsystems within automotive networks, complementing CAN by handling less critical or less data-intensive functions. Both protocols facilitate efficient in-vehicle communication, with CAN optimized for complex, high-reliability systems and LIN focusing on cost-effective, simpler device integration.

Overview of Communication Protocols

CAN bus (Controller Area Network) is a robust vehicle bus standard designed for high-speed communication and real-time data exchange between microcontrollers and devices in automotive and industrial applications. LIN bus (Local Interconnect Network) serves as a cost-effective, lower-speed supplementary protocol primarily used for simpler, less critical subsystems like door modules and climate control. Both protocols enable communication within automotive networks, with CAN supporting multi-master arbitration and error detection, while LIN operates with a single master and multiple slaves in a time-triggered communication scheme.

Architecture and Network Topology

CAN bus features a multi-master architecture supporting high-speed communication up to 1 Mbps, utilizing a differential two-wire twisted pair for robust, noise-resistant data transfer in complex network topologies. LIN bus employs a single-master, multiple-slave architecture designed for low-speed communication around 20 Kbps, using a single-wire physical layer optimal for simple, cost-effective linear or star topologies in automotive subsystems. CAN's decentralized control and message prioritization contrast with LIN's centralized scheduling, reflecting their distinct roles in vehicle network hierarchy and complexity.

Data Transmission Speed and Bandwidth

CAN bus supports data transmission speeds up to 1 Mbps, offering higher bandwidth suitable for complex automotive systems requiring reliable and fast communication. LIN bus operates at a lower speed, typically up to 20 Kbps, designed for simpler, low-cost applications with less stringent bandwidth demands. The significant difference in data rates makes CAN ideal for critical real-time data exchange, while LIN is optimal for slower peripheral device control.

Protocol Complexity and Implementation

CAN bus features a more complex protocol with robust error detection, priority-based message arbitration, and multi-master capabilities, making it ideal for high-speed, safety-critical automotive applications. LIN bus employs a simpler, single-master, multiple-slave architecture with basic error detection, designed for low-cost, low-speed communication in body electronics like window controls and seat adjustments. Implementation of CAN requires more processing power and hardware resources due to its sophisticated frame format and CRC error checking, whereas LIN is easier to implement with minimal hardware and software overhead.

Cost Considerations

CAN bus systems typically incur higher costs due to their complex architecture, faster data rates, and robust error handling features, making them ideal for critical automotive and industrial applications. LIN bus offers a more economical solution with simpler wiring and lower data speeds, which reduces overall implementation and maintenance expenses in less demanding environments. Choosing between CAN and LIN depends on the required network performance and budget constraints, with LIN bus often favored for cost-sensitive applications requiring basic communication.

Applications in Automotive Systems

CAN bus excels in complex automotive systems requiring high-speed, reliable communication for powertrain control, advanced driver-assistance systems (ADAS), and infotainment networks. LIN bus serves cost-effective, low-speed applications such as body electronics, including window controls, seat adjustment, and climate control modules. Together, CAN and LIN buses enable robust, scalable vehicle network architectures supporting diverse automotive functionalities.

Reliability and Fault Tolerance

CAN bus offers superior reliability and fault tolerance compared to LIN bus due to its multi-master architecture, robust error detection, and automatic retransmission mechanisms. CAN supports error confinement and fault containment, enabling network nodes to isolate faulty devices and maintain communication integrity. In contrast, LIN bus is a simpler single-master design with limited error detection, making it less suitable for critical systems requiring high fault tolerance.

Scalability and Flexibility

CAN bus offers superior scalability with its multi-master architecture supporting up to 1,024 nodes, making it ideal for complex automotive and industrial networks. LIN bus, designed for simpler sub-networks, supports up to 16 nodes and operates as a single-master system, limiting its flexibility but ensuring cost-effective solutions for low-speed peripheral communication. The choice between CAN and LIN buses depends on system size and the need for network expansion or integration of diverse electronic control units.

Choosing Between CAN Bus and LIN Bus

Choosing between CAN bus and LIN bus depends on the complexity and speed requirements of the automotive network. CAN bus offers higher data transfer rates of up to 1 Mbps and robust error handling, making it ideal for critical systems like engine control and braking. LIN bus operates at lower speeds around 20 Kbps, providing a cost-effective solution for simpler applications such as window controls and seat adjustments.

Differential signaling

CAN bus uses differential signaling with two wires (CAN_H and CAN_L) for higher noise immunity and faster data rates, while LIN bus employs single-wire signaling optimized for low-cost, low-speed communication in automotive networks.

Master-slave architecture

CAN bus supports multi-master architecture with decentralized control, while LIN bus employs a single-master, multiple-slave architecture for simpler, cost-effective communication in automotive networks.

Bit rate bandwidth

CAN bus supports bit rates up to 1 Mbps, offering higher bandwidth than LIN bus, which typically operates at a maximum of 20 Kbps.

Fault tolerance

CAN bus offers higher fault tolerance with error detection and fault confinement features compared to the simpler, less robust LIN bus designed for low-cost, single-master applications.

Arbitration

CAN bus uses a nondestructive bit-wise arbitration method allowing higher priority messages to dominate bus access, whereas LIN bus relies on a master-slave communication without arbitration, making CAN more suitable for real-time multi-node networks.

Data frame structure

CAN bus data frames feature a complex structure with fields like arbitration ID, control, data, CRC, and acknowledgment, enabling high-speed, priority-based communication, whereas LIN bus data frames use a simpler format with a header containing synchronization and identifier fields followed by a fixed-length data payload optimized for low-cost, single-master, multiple-slave communication.

Event-triggered vs. schedule-triggered

CAN bus operates with an event-triggered protocol enabling dynamic message transmission upon signal changes, whereas LIN bus uses a schedule-triggered protocol with fixed time slots for deterministic communication.

Node addressing

CAN bus uses unique 11- or 29-bit identifiers for message arbitration without explicit node addressing, while LIN bus employs a master-controlled schedule assigning 6-bit node addresses for targeted communication.

Physical layer topology

CAN bus features a multi-master linear bus topology with differential signaling over twisted pair cables, whereas LIN bus employs a single-master, single-wire, single-ended linear topology optimized for low-speed, low-cost applications.

Automotive embedded networks

CAN bus offers higher data rates up to 1 Mbps and robust error handling ideal for complex automotive embedded networks, while LIN bus provides a cost-effective, low-speed solution up to 20 Kbps primarily for simple body electronics.

CAN bus vs LIN bus Infographic

njnir.com

njnir.com