PCBs offer superior durability, reliable electrical connections, and compact design, making them ideal for final product development and mass production. Breadboards facilitate rapid prototyping and testing with easy component insertion and removal but suffer from unstable connections and limited current capacity. Choosing between PCBs and breadboards depends on the project phase, balancing flexibility and professional quality.

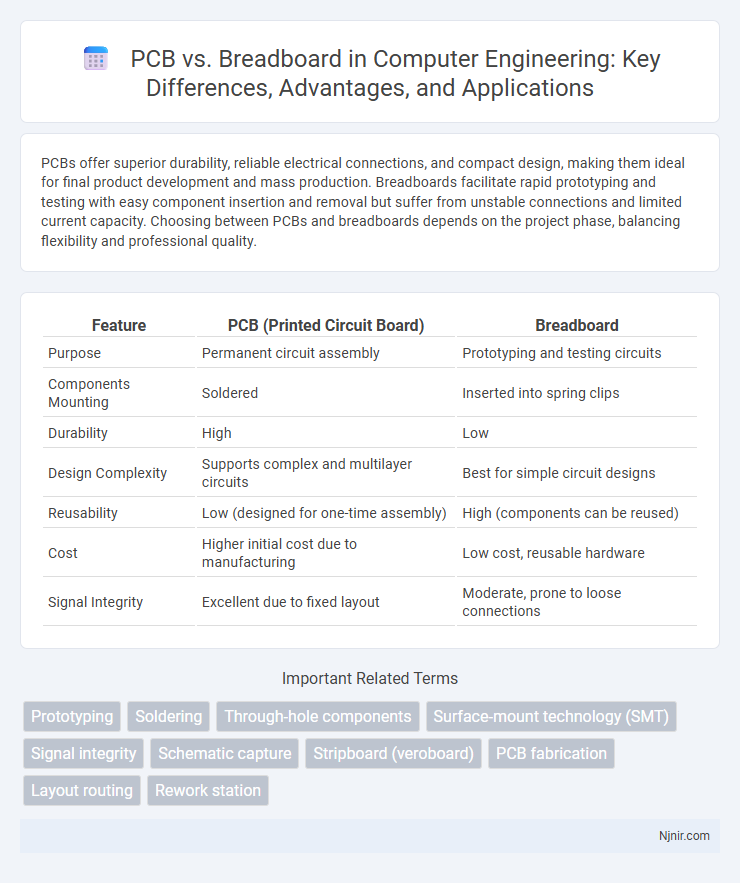

Table of Comparison

| Feature | PCB (Printed Circuit Board) | Breadboard |

|---|---|---|

| Purpose | Permanent circuit assembly | Prototyping and testing circuits |

| Components Mounting | Soldered | Inserted into spring clips |

| Durability | High | Low |

| Design Complexity | Supports complex and multilayer circuits | Best for simple circuit designs |

| Reusability | Low (designed for one-time assembly) | High (components can be reused) |

| Cost | Higher initial cost due to manufacturing | Low cost, reusable hardware |

| Signal Integrity | Excellent due to fixed layout | Moderate, prone to loose connections |

Introduction to PCB and Breadboard

Printed Circuit Boards (PCBs) are rigid or flexible substrates used to mechanically support and electrically connect electronic components through etched copper pathways. Breadboards serve as reusable platforms for prototyping electronic circuits without soldering, featuring a grid of interconnected holes for easy component insertion. PCBs offer permanent, reliable circuit connections ideal for final products, while breadboards enable quick and flexible circuit testing during development stages.

Key Differences Between PCB and Breadboard

Printed Circuit Boards (PCBs) offer permanent, compact, and reliable electrical connections by etching copper pathways on insulating substrates, whereas breadboards provide temporary, flexible prototyping with interconnected holes for component insertion and jumper wires. PCBs enable complex, high-frequency circuit designs with precise and durable soldered joints, while breadboards are limited to low-frequency applications and easily modifiable layouts without soldering. The key differences include durability, electrical performance, and suitability for final product manufacturing versus rapid prototyping and testing.

Applications of PCB in Computer Engineering

Printed Circuit Boards (PCBs) are integral in computer engineering for designing compact, reliable, and high-performance hardware like motherboards, graphic cards, and CPUs. Their precise layout supports efficient signal integrity and power distribution essential for complex computing tasks. PCBs enable mass production of devices with consistent quality, a crucial factor in developing scalable computer systems and embedded devices.

Common Uses of Breadboards in Prototyping

Breadboards are extensively used in prototyping for quickly assembling and testing electronic circuits without soldering, making them ideal for experimental designs and iterative development. Their reusable nature allows engineers and hobbyists to easily modify circuit layouts and components while troubleshooting functionality in real-time. Breadboards serve as essential tools in education and rapid prototyping by enabling the validation of circuit concepts before committing to printed circuit board (PCB) fabrication.

Durability and Reliability Comparison

Printed circuit boards (PCBs) offer superior durability and reliability compared to breadboards due to their rigid construction and soldered connections that prevent loose contacts and signal interference. Breadboards, made from plastic with spring clips, are prone to wear and unreliable connections, especially under mechanical stress or environmental factors like humidity and vibration. PCB's robust design ensures consistent electrical performance and longevity in both prototype and final product applications.

Circuit Design Flexibility: PCB vs Breadboard

Printed Circuit Boards (PCBs) offer superior circuit design flexibility through precise, compact layouts and multi-layer routing, enabling complex and high-speed electronic designs. Breadboards provide easy prototyping with quick component swaps and reconfigurations but are limited by physical size and unreliable connections, making them less suitable for permanent or intricate circuits. PCB designs support custom traces and soldered components, ensuring durability and signal integrity unmatched by breadboard setups.

Cost Implications: PCB versus Breadboard

Printed Circuit Boards (PCBs) generally involve higher initial costs due to design, fabrication, and assembly expenses, but they become cost-effective for large-scale or long-term projects because of their durability and reliability. Breadboards, on the other hand, have low upfront costs and are ideal for prototyping and small-scale development, but they lack permanence and can incur higher labor costs over time due to manual wiring and troubleshooting. Selecting between PCB and breadboard depends heavily on project volume, complexity, and the need for scalability in production costs.

Ease of Assembly and Modification

Breadboards offer exceptional ease of assembly and modification due to their reusable and solderless design, allowing quick prototyping and component swapping without permanent connections. Printed Circuit Boards (PCBs) require soldering, making initial assembly more time-consuming and skill-dependent but providing a robust, durable setup that is less prone to loose connections. Modifying PCBs is more complex, often involving desoldering or redesigning the board, whereas breadboards enable fast iterative changes ideal for experimentation.

Signal Integrity and Performance

Printed Circuit Boards (PCBs) offer superior signal integrity compared to breadboards due to their controlled impedance traces and minimized parasitic capacitance and inductance, which reduce signal distortion and electromagnetic interference. Breadboards are prone to noise and crosstalk because of loose connections and longer, unshielded wiring paths, leading to degraded performance in high-frequency or sensitive analog circuits. For advanced electronic designs requiring reliable high-speed signal transmission, PCBs provide consistent electrical characteristics and enhanced overall performance.

Choosing the Right Platform for Your Project

Choosing between a PCB and a breadboard depends on project complexity and longevity requirements. PCBs provide durable, compact, and reliable circuit connections, ideal for final products and mass production, while breadboards offer quick, flexible prototyping with easily adjustable components for early development stages. Consider factors like signal integrity, component density, and project scalability to determine the most efficient platform.

Prototyping

PCBs provide durable, reliable connections ideal for advanced prototyping, while breadboards offer quick, flexible setups for initial circuit testing and design iteration.

Soldering

PCB offers permanent, reliable soldered connections with precise component placement, whereas breadboards allow temporary, solder-free prototyping ideal for quick circuit testing.

Through-hole components

Through-hole components offer reliable mechanical strength and better electrical connectivity when mounted on PCBs compared to the temporary and less durable connections on breadboards.

Surface-mount technology (SMT)

Surface-mount technology (SMT) on PCBs offers higher component density, improved electrical performance, and greater durability compared to the temporary and prototyping nature of breadboards.

Signal integrity

PCB designs maintain superior signal integrity compared to breadboards due to controlled impedance, minimized crosstalk, and reduced parasitic capacitance and inductance.

Schematic capture

Schematic capture enables precise, reusable circuit designs on PCBs, offering superior reliability and integration compared to the temporary, manual wiring of breadboards.

Stripboard (veroboard)

Stripboard (veroboard) offers a durable alternative to breadboards by providing pre-drilled copper strips for permanent soldered connections, making it ideal for prototyping circuits transitioning from breadboard layouts to finalized PCBs.

PCB fabrication

PCB fabrication involves precise layering, etching, and solder mask application to create durable, reliable circuits, contrasting with the temporary and manual wiring of breadboards.

Layout routing

PCB layout routing offers precise, compact, and durable circuit connections with optimized signal integrity and reduced noise compared to the temporary and flexible but less reliable and cluttered routing on breadboards.

Rework station

Rework stations provide precise soldering control and heat management essential for repairing PCBs, while breadboards are primarily used for temporary prototyping without soldering.

PCB vs Breadboard Infographic

njnir.com

njnir.com