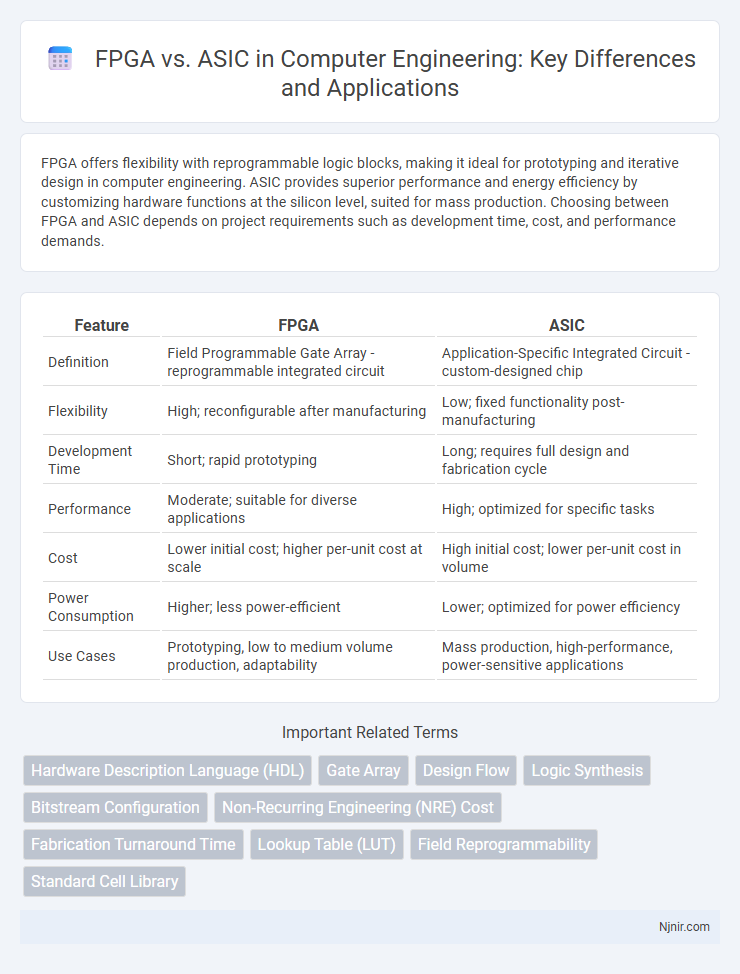

FPGA offers flexibility with reprogrammable logic blocks, making it ideal for prototyping and iterative design in computer engineering. ASIC provides superior performance and energy efficiency by customizing hardware functions at the silicon level, suited for mass production. Choosing between FPGA and ASIC depends on project requirements such as development time, cost, and performance demands.

Table of Comparison

| Feature | FPGA | ASIC |

|---|---|---|

| Definition | Field Programmable Gate Array - reprogrammable integrated circuit | Application-Specific Integrated Circuit - custom-designed chip |

| Flexibility | High; reconfigurable after manufacturing | Low; fixed functionality post-manufacturing |

| Development Time | Short; rapid prototyping | Long; requires full design and fabrication cycle |

| Performance | Moderate; suitable for diverse applications | High; optimized for specific tasks |

| Cost | Lower initial cost; higher per-unit cost at scale | High initial cost; lower per-unit cost in volume |

| Power Consumption | Higher; less power-efficient | Lower; optimized for power efficiency |

| Use Cases | Prototyping, low to medium volume production, adaptability | Mass production, high-performance, power-sensitive applications |

Overview of FPGA and ASIC Technologies

FPGA (Field-Programmable Gate Array) technology offers reconfigurable logic blocks and programmable interconnects, enabling flexible hardware design and prototyping. ASIC (Application-Specific Integrated Circuit) technology provides custom-designed silicon chips optimized for specific applications, delivering superior performance and lower power consumption. FPGAs allow iterative development and rapid deployment, while ASICs are suited for high-volume production with fixed functionality.

Key Architectural Differences

Field-Programmable Gate Arrays (FPGAs) feature a flexible, reconfigurable architecture composed of programmable logic blocks and interconnects, enabling rapid prototyping and iterative design changes. Application-Specific Integrated Circuits (ASICs) are designed with fixed, custom-tailored logic gates optimized for performance, power efficiency, and area, making them ideal for high-volume production. Unlike ASICs, FPGAs rely on lookup tables (LUTs) and configurable routing resources, which incur higher latency and power consumption but offer post-manufacturing adaptability.

Design Flexibility and Customization

FPGAs offer unparalleled design flexibility, allowing engineers to reprogram and modify hardware configurations post-manufacturing to adapt to changing requirements or prototype new designs rapidly. ASICs provide high customization tailored for specific applications, delivering optimal performance, power efficiency, and reduced unit cost at scale, but lack the ability to be reconfigured after fabrication. The choice between FPGA and ASIC hinges on the trade-off between adaptability and fixed, high-efficiency customization for dedicated tasks.

Performance and Speed Comparison

FPGA devices typically offer lower maximum clock speeds compared to ASICs due to their programmable architecture and inherent routing delays, resulting in reduced raw performance. ASICs, being custom-designed for specific applications, achieve significantly higher performance and speed with optimized circuit paths and reduced latency. For high-frequency and compute-intensive tasks, ASICs outperform FPGAs by delivering faster processing speeds and higher throughput.

Power Consumption Considerations

FPGA devices typically consume more power than ASICs due to their reconfigurable architecture and general-purpose logic blocks, which introduce overhead and inefficiencies in switching activity. ASICs offer optimized power consumption by tailoring transistor-level design for specific applications, enabling lower leakage currents and dynamic power through precise circuit techniques. When power efficiency is critical, ASICs remain the preferred choice for applications demanding high performance with minimal energy consumption.

Development Time and Cost Analysis

FPGA development typically offers shorter time-to-market due to its reprogrammable nature, enabling rapid prototyping and iterative testing without fabrication delays. ASIC design requires extensive upfront investment in design, verification, and fabrication, resulting in higher initial costs but lower per-unit expenses for large-scale production. Companies must weigh FPGA's flexibility and lower non-recurring engineering (NRE) costs against ASIC's cost efficiency and performance benefits when committing to volume manufacturing.

Scalability and Production Volume

FPGAs offer high scalability with flexible reconfiguration, making them ideal for low to medium production volumes and rapid prototyping. ASICs provide superior performance and cost efficiency at high production volumes due to their fixed, application-specific design. Enterprises targeting large-scale deployment benefit from ASICs' economies of scale, while FPGA suits demand-driven or evolving applications requiring adaptability.

Application Suitability and Use Cases

FPGA excels in prototyping and low to medium volume production due to its reconfigurability and rapid deployment, making it ideal for applications such as aerospace, defense, and telecommunications where flexibility and adaptability are critical. ASIC offers superior performance, power efficiency, and lower unit cost at high volumes, making it the preferred choice for consumer electronics, mobile devices, and high-performance computing where efficiency and scalability are paramount. The decision between FPGA and ASIC depends on project timelines, budget constraints, production volumes, and specific application requirements.

Future Trends in FPGA and ASIC Development

Future trends in FPGA development emphasize enhanced integration of AI and machine learning accelerators, enabling more adaptive and power-efficient designs suited for edge computing applications. ASIC innovation focuses on advanced process nodes and 3D chip stacking to achieve higher performance and lower power consumption for mass-production in mobile and high-performance computing sectors. Both FPGA and ASIC technologies increasingly incorporate heterogeneous computing architectures to meet growing demands for specialized processing and real-time data handling.

Choosing Between FPGA and ASIC for Your Project

Choosing between FPGA and ASIC for your project depends on factors such as development cost, time-to-market, and production volume. FPGAs offer flexibility and faster prototyping with reprogrammable hardware, ideal for small to medium runs or evolving designs. ASICs deliver high performance and lower unit costs at scale, making them suitable for large-volume, fixed-function applications with stringent power and speed requirements.

Hardware Description Language (HDL)

FPGA development relies on versatile Hardware Description Languages (HDLs) like VHDL and Verilog for reconfigurable logic design, whereas ASIC design uses HDLs to create fixed, custom silicon chips optimized for specific applications.

Gate Array

Gate array ASICs offer customizable logic blocks with faster design cycles compared to FPGAs but lack the reprogrammability and flexibility of FPGA architectures.

Design Flow

FPGA design flow involves rapid prototyping with reusable programmable logic and minimal manufacturing steps, while ASIC design flow requires extensive custom chip design, verification, fabrication, and longer time-to-market.

Logic Synthesis

FPGA logic synthesis translates high-level designs into configurable logic blocks enabling rapid prototyping, while ASIC synthesis optimizes circuits for fixed, high-performance, and low-power custom silicon layouts.

Bitstream Configuration

FPGA devices utilize bitstream configuration files to dynamically program logic functions after manufacturing, whereas ASICs have fixed, hardwired circuits with no reconfigurable bitstream capability.

Non-Recurring Engineering (NRE) Cost

FPGA's Non-Recurring Engineering (NRE) costs are significantly lower than ASIC's due to the absence of expensive mask set fabrication and prototype iterations, making FPGAs more cost-effective for low to medium volume production.

Fabrication Turnaround Time

FPGA fabrication turnaround time is typically measured in weeks due to pre-manufactured programmable logic, while ASIC requires several months for custom silicon design and fabrication.

Lookup Table (LUT)

Lookup Tables (LUTs) in FPGAs provide flexible, reconfigurable logic functions, whereas ASICs use fixed, optimized gate-level logic for higher performance and lower power consumption.

Field Reprogrammability

FPGAs offer field reprogrammability allowing real-time hardware updates, whereas ASICs have fixed functionality with no post-manufacturing reprogramming capability.

Standard Cell Library

Standard cell libraries in ASIC design offer optimized, pre-characterized logic components for higher performance and lower power consumption, whereas FPGAs use configurable logic blocks with fixed standard cells, resulting in greater flexibility but generally lower efficiency.

FPGA vs ASIC Infographic

njnir.com

njnir.com