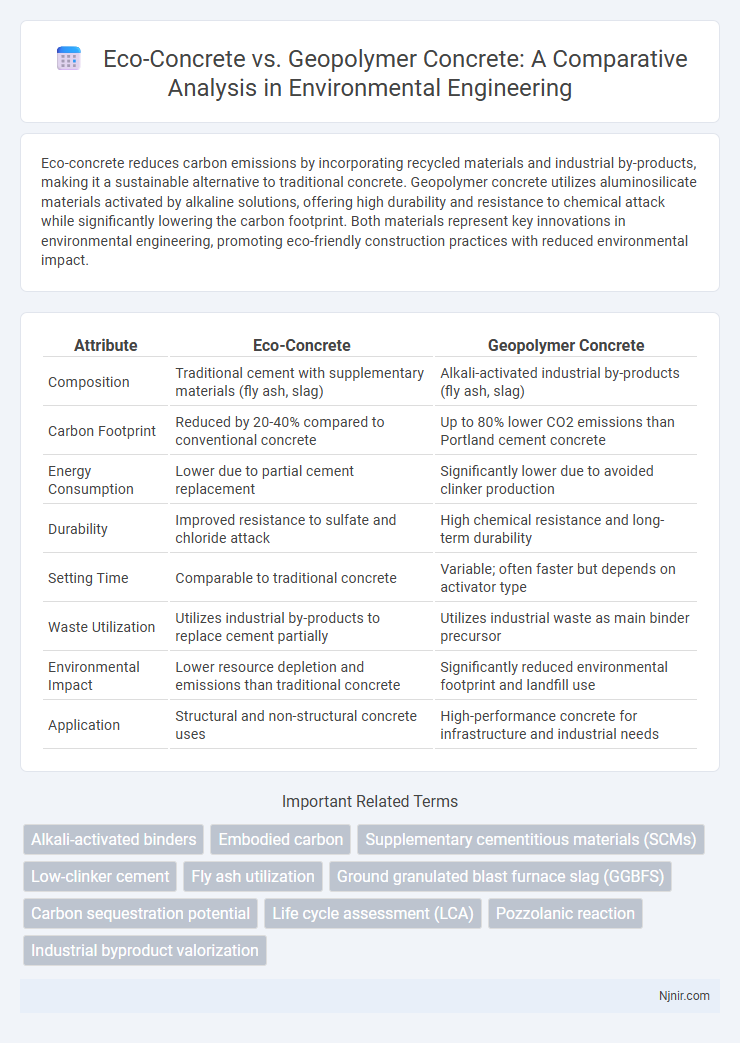

Eco-concrete reduces carbon emissions by incorporating recycled materials and industrial by-products, making it a sustainable alternative to traditional concrete. Geopolymer concrete utilizes aluminosilicate materials activated by alkaline solutions, offering high durability and resistance to chemical attack while significantly lowering the carbon footprint. Both materials represent key innovations in environmental engineering, promoting eco-friendly construction practices with reduced environmental impact.

Table of Comparison

| Attribute | Eco-Concrete | Geopolymer Concrete |

|---|---|---|

| Composition | Traditional cement with supplementary materials (fly ash, slag) | Alkali-activated industrial by-products (fly ash, slag) |

| Carbon Footprint | Reduced by 20-40% compared to conventional concrete | Up to 80% lower CO2 emissions than Portland cement concrete |

| Energy Consumption | Lower due to partial cement replacement | Significantly lower due to avoided clinker production |

| Durability | Improved resistance to sulfate and chloride attack | High chemical resistance and long-term durability |

| Setting Time | Comparable to traditional concrete | Variable; often faster but depends on activator type |

| Waste Utilization | Utilizes industrial by-products to replace cement partially | Utilizes industrial waste as main binder precursor |

| Environmental Impact | Lower resource depletion and emissions than traditional concrete | Significantly reduced environmental footprint and landfill use |

| Application | Structural and non-structural concrete uses | High-performance concrete for infrastructure and industrial needs |

Introduction to Eco-Concrete and Geopolymer Concrete

Eco-concrete incorporates recycled materials such as fly ash, slag, and recycled aggregates to reduce carbon footprint and minimize environmental impact compared to traditional concrete. Geopolymer concrete utilizes industrial by-products like fly ash or metakaolin activated by alkaline solutions, offering enhanced durability and significantly lower CO2 emissions. Both eco-concrete and geopolymer concrete present sustainable alternatives aimed at reducing greenhouse gas emissions in the construction industry while maintaining structural performance.

Material Composition and Source Sustainability

Eco-concrete typically incorporates recycled aggregates, industrial byproducts like fly ash or slag, and low-carbon cement alternatives to reduce environmental impact, emphasizing circular economy principles. Geopolymer concrete relies on aluminosilicate materials such as fly ash, slag, or metakaolin activated by alkaline solutions, offering a sustainable alternative by significantly lowering CO2 emissions compared to conventional Portland cement. Both materials prioritize source sustainability by utilizing industrial waste and reducing reliance on natural resources, but geopolymer concrete often achieves superior carbon footprint reduction due to its minimal cement content and energy-efficient chemical synthesis.

Environmental Impact and Carbon Footprint

Eco-concrete significantly reduces carbon emissions by incorporating recycled materials such as fly ash and slag, minimizing cement usage which is a major CO2 contributor in traditional concrete production. Geopolymer concrete offers an even lower carbon footprint by utilizing industrial by-products like fly ash and metakaolin, which require less energy-intensive processing compared to Portland cement. Both materials enhance environmental sustainability, but geopolymer concrete often achieves up to 80% reduction in carbon emissions relative to conventional concrete, making it a superior choice for low-impact construction.

Mechanical Properties and Durability

Eco-concrete exhibits enhanced mechanical properties such as improved compressive strength and reduced shrinkage due to the use of recycled aggregates and supplementary cementitious materials. Geopolymer concrete demonstrates superior durability, resisting chemical attacks, high temperatures, and aggressive environmental conditions owing to its aluminosilicate binder system. Both materials offer sustainable alternatives with eco-concrete excelling in structural performance and geopolymer concrete providing exceptional longevity in harsh environments.

Energy Consumption During Production

Eco-concrete typically reduces energy consumption by incorporating recycled materials and industrial byproducts like fly ash, which lowers the demand for energy-intensive Portland cement. Geopolymer concrete further decreases production energy by utilizing aluminosilicate materials activated with alkaline solutions, eliminating the need for traditional cement firing processes. Studies show geopolymer concrete can reduce energy consumption by up to 60% compared to conventional Portland cement-based eco-concrete, contributing significantly to carbon footprint reduction in construction.

Performance in Aggressive Environments

Eco-concrete and geopolymer concrete both exhibit enhanced performance in aggressive environments by offering superior chemical resistance and durability compared to traditional Portland cement concrete. Geopolymer concrete, composed primarily of aluminosilicate materials activated by alkaline solutions, demonstrates exceptional resistance to acid, sulfate, and chloride attacks, making it ideal for industrial and marine applications. Eco-concrete, which integrates recycled materials and supplementary cementitious components, improves sustainability while maintaining moderate resistance to environmental degradation, though geopolymer concrete generally outperforms it in highly corrosive conditions.

Cost Comparison and Economic Feasibility

Eco-concrete typically incurs higher initial costs due to the use of recycled aggregates and supplementary cementitious materials, yet its long-term savings stem from durability and reduced environmental penalties. Geopolymer concrete offers competitive pricing by utilizing industrial by-products like fly ash and slag, which lower raw material expenses and energy consumption. Economic feasibility favors geopolymer concrete in regions with abundant industrial waste, while eco-concrete appeals in markets prioritizing recycled content despite modest cost premiums.

Industrial Applications and Case Studies

Eco-concrete and geopolymer concrete exhibit strong potential in industrial applications, with eco-concrete primarily reducing carbon emissions through supplementary cementitious materials like fly ash and slag, while geopolymer concrete uses industrial byproducts such as metakaolin or fly ash activated by alkaline solutions to achieve superior chemical resistance and thermal stability. Case studies in heavy industry demonstrate geopolymer concrete's effectiveness in refractory linings and waste containment facilities due to its high durability and resistance to aggressive chemicals, whereas eco-concrete has been successfully implemented in large-scale infrastructure projects such as highways and bridges to minimize environmental impact without compromising structural integrity. Both materials contribute to sustainable industrial construction by enhancing durability and reducing greenhouse gas emissions associated with traditional Portland cement concrete.

Challenges and Limitations

Eco-concrete faces challenges such as limited long-term durability data and variability in material sources, impacting consistency in performance. Geopolymer concrete struggles with the need for specialized raw materials like fly ash or slag, and issues related to high alkalinity, which can limit its widespread adoption. Both types require further research to address curing conditions and standardization for large-scale infrastructure applications.

Future Trends and Innovations in Green Concrete

Eco-concrete and geopolymer concrete represent cutting-edge advancements in sustainable construction materials, with future trends emphasizing enhanced durability, carbon sequestration capabilities, and resource-efficient manufacturing processes. Innovations include incorporating industrial byproducts like fly ash and slag to reduce carbon footprint, developing hybrid mixes for improved mechanical performance, and integrating nanotechnology to optimize microstructure for longevity. Ongoing research targets scalable production methods and lifecycle assessments to enable widespread adoption in green building certifications and low-impact infrastructure projects.

Alkali-activated binders

Alkali-activated binders in geopolymer concrete offer superior environmental benefits and durability compared to traditional eco-concrete by utilizing industrial byproducts like fly ash and slag to reduce carbon emissions and enhance mechanical performance.

Embodied carbon

Geopolymer concrete reduces embodied carbon by up to 80% compared to traditional eco-concrete methods, making it a significantly more sustainable construction material.

Supplementary cementitious materials (SCMs)

Supplementary cementitious materials (SCMs) in eco-concrete enhance durability and reduce carbon emissions by partially replacing Portland cement, whereas geopolymer concrete utilizes industrial byproducts like fly ash or slag activated by alkaline solutions, offering a low-carbon alternative with comparable or superior performance.

Low-clinker cement

Low-clinker cement in eco-concrete reduces CO2 emissions by minimizing clinker content, whereas geopolymer concrete entirely replaces traditional cement with aluminosilicate binders for superior sustainability and durability.

Fly ash utilization

Fly ash utilization in geopolymer concrete significantly reduces carbon emissions compared to eco-concrete by replacing traditional cement with industrial byproducts for enhanced sustainability.

Ground granulated blast furnace slag (GGBFS)

Ground Granulated Blast Furnace Slag (GGBFS) enhances eco-concrete by reducing cement usage and improving durability, while in geopolymer concrete, GGBFS acts as a key aluminosilicate source that enables alkali activation for sustainable, high-performance binders.

Carbon sequestration potential

Geopolymer concrete offers higher carbon sequestration potential than eco-concrete by utilizing industrial waste materials that chemically trap CO2 within its hardened matrix, significantly reducing overall carbon emissions.

Life cycle assessment (LCA)

Life cycle assessment (LCA) reveals that geopolymer concrete significantly reduces carbon emissions and energy consumption compared to traditional eco-concrete by utilizing industrial waste materials and eliminating cement production.

Pozzolanic reaction

Eco-concrete utilizes natural pozzolanic materials like fly ash and silica fume to enhance strength and durability through the pozzolanic reaction, while geopolymer concrete relies on alkali-activated aluminosilicate precursors producing a geopolymerization reaction that also delivers superior mechanical and chemical properties.

Industrial byproduct valorization

Geopolymer concrete maximizes industrial byproduct valorization by utilizing fly ash and slag as primary binders, significantly reducing cement consumption and carbon emissions compared to eco-concrete formulations.

eco-concrete vs geopolymer concrete Infographic

njnir.com

njnir.com