Microplastic filtering techniques primarily target particles larger than 1 micrometer, effectively capturing visible and larger plastic fragments in water treatment processes. Nanoplastic filtering requires advanced membrane technology capable of removing particles smaller than 100 nanometers, posing greater challenges due to the nanoscale size and potential chemical interactions. Combining both methods enhances overall filtration efficiency, addressing diverse pollution scales and improving environmental safety.

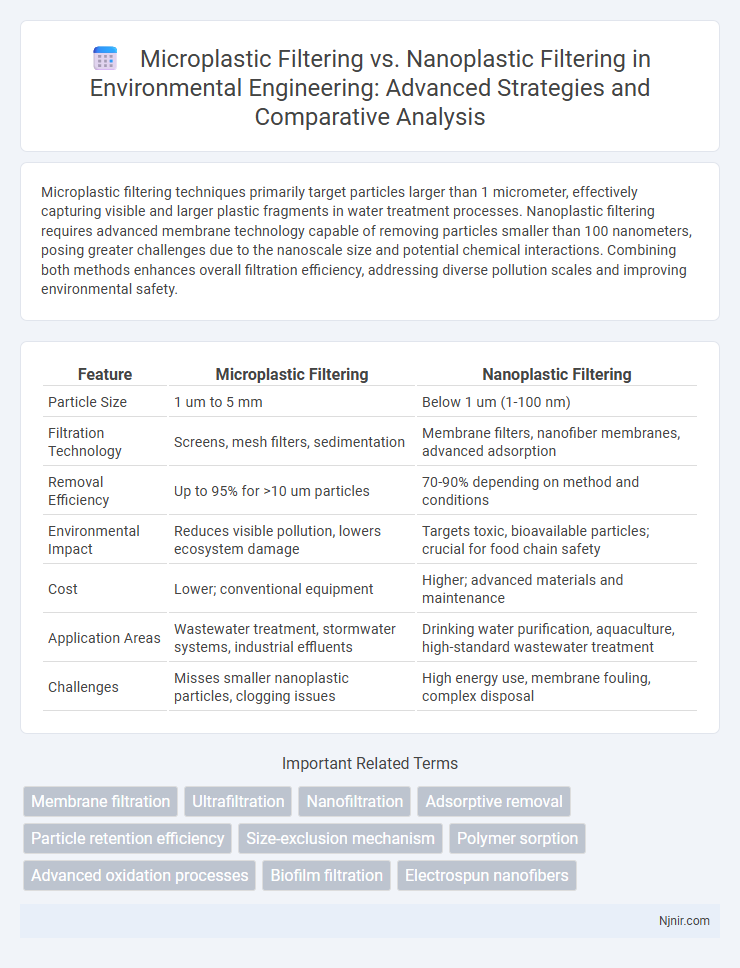

Table of Comparison

| Feature | Microplastic Filtering | Nanoplastic Filtering |

|---|---|---|

| Particle Size | 1 um to 5 mm | Below 1 um (1-100 nm) |

| Filtration Technology | Screens, mesh filters, sedimentation | Membrane filters, nanofiber membranes, advanced adsorption |

| Removal Efficiency | Up to 95% for >10 um particles | 70-90% depending on method and conditions |

| Environmental Impact | Reduces visible pollution, lowers ecosystem damage | Targets toxic, bioavailable particles; crucial for food chain safety |

| Cost | Lower; conventional equipment | Higher; advanced materials and maintenance |

| Application Areas | Wastewater treatment, stormwater systems, industrial effluents | Drinking water purification, aquaculture, high-standard wastewater treatment |

| Challenges | Misses smaller nanoplastic particles, clogging issues | High energy use, membrane fouling, complex disposal |

Overview of Microplastic and Nanoplastic Pollution

Microplastic pollution consists of plastic particles smaller than 5 millimeters, commonly originating from cosmetic products, clothing fibers, and degraded larger plastics, while nanoplastic pollution refers to even smaller particles under 100 nanometers, often resulting from the further breakdown of microplastics and industrial processes. Microplastics accumulate in marine environments, soil, and air, affecting aquatic life and entering the food chain, whereas nanoplastics pose greater risks due to their ability to penetrate biological membranes and cause cellular damage. Effective filtering technologies target specific particle sizes, with microplastic filters often using mesh screens or sedimentation, while nanoplastic filtration requires advanced methods such as membrane filtration and nanotechnology-based adsorbents to capture ultra-fine particles.

Key Differences Between Microplastics and Nanoplastics

Microplastic filtering targets particles ranging from 1 micrometer to 5 millimeters, primarily using coarse filtration techniques, whereas nanoplastic filtering addresses particles smaller than 1 micrometer, necessitating advanced methods like membrane filtration or adsorption. Microplastics originate from the breakdown of larger plastics and are often visible to the naked eye, while nanoplastics result from further degradation and pose greater health risks due to their ability to penetrate biological barriers. The key differences lie in particle size, filtration complexity, and environmental impact, with nanoplastics requiring more intricate removal technologies because of their minute scale and potential toxicity.

Sources and Pathways of Plastics in the Environment

Microplastic filtering targets particles larger than 1 micrometer, primarily originating from degraded plastic debris like cosmetic microbeads, synthetic textiles, and tire wear, which enter the environment through wastewater and runoff. Nanoplastic filtering addresses particles smaller than 1 micrometer produced by the further breakdown of microplastics and industrial processes, often disseminating through atmospheric deposition and aquatic systems. Both filters aim to reduce the release of plastics from key pathways such as sewage treatment plants, stormwater overflow, and agricultural runoff, yet nanoplastic filtration remains more challenging due to particle size and widespread distribution.

Current Technologies for Microplastic Filtering

Current technologies for microplastic filtering primarily utilize advanced membrane filtration, such as microfiltration and ultrafiltration, effectively capturing particles typically larger than 0.1 micrometers. Techniques like activated carbon adsorption and coagulation-flocculation are also employed to enhance removal efficiency in wastewater treatment plants. Emerging innovations focus on optimizing filter pore size and material properties to improve retention of microplastics while maintaining system throughput.

Advances in Nanoplastic Removal Techniques

Nanoplastic removal techniques have advanced through the development of innovative filtration materials such as graphene-based membranes and bio-inspired nanofibers, enabling the capture of particles smaller than 100 nanometers that traditional microplastic filters miss. Emerging methods like photocatalytic degradation and magnetic nanoparticle aggregation enhance efficiency by breaking down or collecting nanoplastics from complex aquatic environments. These cutting-edge approaches significantly improve water purification processes, targeting pollutants at a nanoscale precision unattainable by conventional microplastic filtering technologies.

Efficiency Comparison: Microplastic vs Nanoplastic Filters

Microplastic filters effectively capture particles ranging from 5 micrometers to several millimeters, achieving filtration efficiencies of up to 95% in wastewater treatment plants. In contrast, nanoplastic filters target particles smaller than 1 micrometer, but their efficiency often drops below 80% due to challenges in trapping ultrafine particles and higher energy demands. Advances in membrane technology and electrospun nanofibers are improving nanoplastic filtration performance, but microplastic filters remain more efficient and cost-effective for large-scale applications.

Environmental Impact of Incomplete Plastic Removal

Incomplete removal of microplastics and nanoplastics results in significant environmental contamination, as these particles persist in aquatic and soil ecosystems, disrupting food chains and harming wildlife health. Microplastic filters often fail to capture particles smaller than 5 micrometers, while nanoplastic filtration poses greater challenges due to particle size below 100 nanometers, leading to widespread bioaccumulation and toxicological effects. Inefficient filtration systems contribute to the continuous release of plastics, exacerbating pollution, affecting water quality, and threatening biodiversity on a global scale.

Challenges in Detecting and Filtering Nanoplastics

Detecting nanoplastics presents significant challenges due to their minuscule size, often below 100 nanometers, which hinders standard filtration and analytical methods effective for microplastics larger than 1 millimeter. Conventional microplastic filters fail to capture nanoplastics, necessitating advanced techniques such as membrane filtration combined with spectroscopy or electron microscopy for identification and removal. The high surface area-to-volume ratio of nanoplastics also leads to aggregation and complex interactions with environmental matrices, complicating filtration efficiency and detection accuracy.

Future Innovations in Plastic Filtration Systems

Future innovations in plastic filtration systems prioritize advanced nanotechnology to enhance nanoplastic filtering efficiency beyond conventional microplastic removal capabilities. Emerging filters incorporate graphene-based membranes and electrospun nanofibers, enabling selective capture of particles smaller than 100 nanometers with higher permeability and durability. Integration of AI-driven monitoring systems promises real-time detection and adaptive filtration adjustments, significantly improving environmental plastic remediation efforts.

Policy Implications and Regulatory Considerations

Microplastic filtering technologies are currently prioritized in environmental regulations due to their established impact on marine ecosystems and human health, while nanoplastic filtering remains less regulated because of limited scientific data and detection challenges. Policymakers face gaps in standardized monitoring methods for nanoplastics, necessitating regulatory frameworks that integrate emerging scientific evidence to address potential risks effectively. Enhanced collaboration between regulatory bodies, researchers, and industry stakeholders is crucial to develop adaptive policies that respond to the evolving understanding of both microplastic and nanoplastic pollution.

Membrane filtration

Membrane filtration effectively removes microplastics larger than 1 micron while nanoplastic removal requires advanced ultrafiltration or nanofiltration membranes with pore sizes below 100 nanometers.

Ultrafiltration

Ultrafiltration effectively filters microplastics by removing particles typically larger than 0.01 microns but requires advanced membrane technology to capture nanoplastics smaller than 0.001 microns due to their ultrafine size.

Nanofiltration

Nanofiltration effectively removes nanoplastics by targeting particles smaller than 1 nanometer, offering higher filtration precision compared to microplastic filtering methods that capture larger particles above 1 micrometer.

Adsorptive removal

Adsorptive removal of microplastics utilizes larger surface area materials for capturing particles typically above 1 micron, while nanoplastic filtering demands advanced nanomaterials with enhanced adsorption capacities to effectively target particles below 100 nanometers.

Particle retention efficiency

Nanoplastic filtering achieves higher particle retention efficiency than microplastic filtering due to its ability to capture particles smaller than 100 nanometers, whereas microplastic filters typically retain particles larger than 1 micrometer.

Size-exclusion mechanism

Microplastic filtering targets particles typically larger than 1 micrometer using size-exclusion membranes with pore sizes designed to block particles above this threshold, whereas nanoplastic filtering requires advanced nanoscale membranes or materials with pore sizes below 100 nanometers to effectively capture nanoplastics through precise size-exclusion mechanisms.

Polymer sorption

Nanoplastic filtering exhibits enhanced polymer sorption efficiency compared to microplastic filtering due to the increased surface area-to-volume ratio and higher adsorption sites inherent in nanoplastics.

Advanced oxidation processes

Advanced oxidation processes effectively degrade nanoplastics due to their smaller size and higher reactivity, while microplastic filtering primarily relies on physical separation methods.

Biofilm filtration

Biofilm filtration effectively enhances microplastic removal by promoting microbial degradation, while nanoplastic filtering remains challenging due to smaller particle size and limited biofilm interaction.

Electrospun nanofibers

Electrospun nanofibers demonstrate superior efficiency in filtering nanoplastics compared to microplastics due to their high surface area and tunable pore sizes optimized for capturing particles below 100 nanometers.

Microplastic filtering vs Nanoplastic filtering Infographic

njnir.com

njnir.com