Microplastic filtration effectively removes particles larger than 1 micron, reducing visible pollution in water systems. Nanomaterial filtration targets smaller contaminants, including nanoplastics and dissolved toxins, offering a higher purification efficiency at the molecular level. Combining both methods enhances overall water quality by addressing a broader spectrum of pollutants in environmental engineering applications.

Table of Comparison

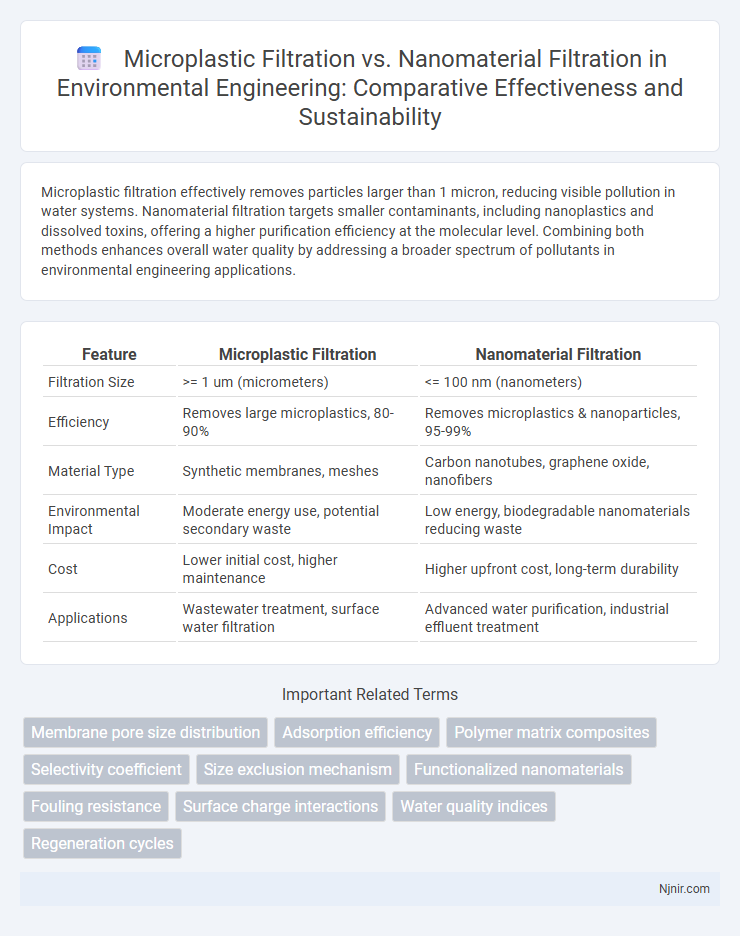

| Feature | Microplastic Filtration | Nanomaterial Filtration |

|---|---|---|

| Filtration Size | >= 1 um (micrometers) | <= 100 nm (nanometers) |

| Efficiency | Removes large microplastics, 80-90% | Removes microplastics & nanoparticles, 95-99% |

| Material Type | Synthetic membranes, meshes | Carbon nanotubes, graphene oxide, nanofibers |

| Environmental Impact | Moderate energy use, potential secondary waste | Low energy, biodegradable nanomaterials reducing waste |

| Cost | Lower initial cost, higher maintenance | Higher upfront cost, long-term durability |

| Applications | Wastewater treatment, surface water filtration | Advanced water purification, industrial effluent treatment |

Introduction to Microplastic and Nanomaterial Filtration

Microplastic filtration targets particles typically ranging from 1 micrometer to 5 millimeters, utilizing mesh-based filters and advanced sieving techniques to remove plastic debris from water sources. Nanomaterial filtration employs engineered nanoparticles, such as graphene oxide and carbon nanotubes, to capture smaller contaminants at the molecular level, enabling higher filtration precision and efficiency. These technologies address different scales of pollution, with microplastic filtration focusing on visible plastic fragments and nanomaterial filtration enhancing pollutant removal in water treatment processes.

Sources and Environmental Impact of Microplastics

Microplastic filtration targets particles typically between 1 micrometer and 5 millimeters, originating from sources such as synthetic textiles, tire wear, and cosmetic products, which heavily contaminate aquatic environments and soil. Nanomaterial filtration can capture smaller nanoparticles, often below 100 nanometers, enabling removal of more elusive microplastic fragments that originate from plastic degradation and manufacturing processes. Effective filtration of both microplastics and nanoplastics is critical to reducing their pervasive environmental impacts, including toxicity to marine life and bioaccumulation in food webs.

Overview of Nanomaterial Contaminants

Nanomaterial contaminants pose unique challenges in water filtration due to their ultra-small size, often below 100 nanometers, which allows them to bypass traditional microplastic filtration systems designed for larger particles. Compared to microplastic filtration, nanomaterial filtration requires advanced materials like graphene oxide membranes, carbon nanotubes, and metal-organic frameworks that can selectively capture and degrade nanoparticles. Effective removal of nanomaterials is critical, as their high surface area and reactivity may induce toxicity in aquatic ecosystems and human health through bioaccumulation.

Filtration Technologies for Microplastics

Microplastic filtration technologies primarily utilize physical barriers like membrane filters and advanced mesh materials capable of capturing particles larger than 1 micrometer, while nanomaterial filtration incorporates engineered nanoparticles and nanofibers designed to trap particles down to the nanometer scale. Membrane filtration methods, including microfiltration and ultrafiltration, effectively reduce microplastic pollution in water treatment by targeting particle sizes between 0.1 and 10 micrometers. Nanomaterial filtration enhances removal efficiency through high surface area adsorption and catalytic degradation, offering promising solutions for microplastic contaminants that evade conventional filters.

Filtration Technologies for Nanomaterials

Nanomaterial filtration technologies utilize advanced materials like graphene oxide membranes and carbon nanotubes to achieve superior removal efficiency of contaminants at the nanoscale, surpassing traditional microplastic filtration methods. These filtration systems exploit high surface area and tunable pore sizes to target particles as small as a few nanometers, enabling effective separation of heavy metals, organic pollutants, and viruses. Ongoing developments in nanomaterial-based filters emphasize durability, reusability, and enhanced permeability without sacrificing filtration performance.

Efficiency Comparison: Microplastic vs Nanomaterial Filtration

Microplastic filtration efficiency typically ranges from 70% to 90% depending on filter pore size and media, effectively capturing particles larger than 1 micron. Nanomaterial filtration, leveraging materials like graphene oxide and carbon nanotubes, achieves over 95% removal rates for particles as small as a few nanometers due to their high surface area and adsorption properties. Nanomaterial filters outperform traditional microplastic filters by providing superior contaminant retention, faster filtration rates, and enhanced durability in water treatment applications.

Challenges in Detecting and Removing Microplastics

Detecting and removing microplastics poses significant challenges due to their heterogeneous sizes and complex chemical compositions, which often evade conventional filtration systems. Microplastic filtration struggles with clogging and low retention efficiency, especially for particles below 20 micrometers, whereas nanomaterial filtration offers enhanced adsorption and catalytic degradation capabilities but faces scalability and environmental safety concerns. Advanced characterization techniques like Raman spectroscopy and electron microscopy are essential for accurate identification, yet integrating these with effective real-time filtration remains a critical hurdle in environmental remediation efforts.

Advancements in Nanomaterial Filtration Techniques

Advancements in nanomaterial filtration techniques have significantly enhanced the removal efficiency of pollutants at the molecular level, outperforming traditional microplastic filtration methods. Nanomaterials such as graphene oxide, carbon nanotubes, and metal-organic frameworks offer superior surface area, selectivity, and reusability for capturing contaminants including microplastics, heavy metals, and organic toxins. These innovations enable more sustainable and cost-effective water treatment solutions, addressing the limitations of conventional filtration systems.

Environmental and Health Implications of Incomplete Filtration

Incomplete filtration of microplastics results in persistent environmental contamination, leading to bioaccumulation in aquatic organisms and potential disruption of ecosystems. Nanomaterial filtration, while more efficient in capturing smaller particles, poses risks due to nanoparticle release that can cause toxicological effects on human health and aquatic life if not properly managed. Both filtration methods require stringent control to prevent secondary pollution and minimize long-term environmental and health impacts.

Future Prospects in Filtration Strategies

Advancements in nanomaterial filtration offer superior efficiency in removing microplastics at the molecular level, enabling the capture of particles smaller than traditional microplastic filters. Future prospects emphasize integrating nanomaterials like graphene oxide and carbon nanotubes into filtration systems to enhance adsorption capacity and durability. Scaling nanomaterial-based filters while ensuring environmental safety and cost-effectiveness remains critical for widespread adoption in water treatment technologies.

Membrane pore size distribution

Nanomaterial filtration achieves finer separation with membrane pore sizes typically below 100 nanometers, enabling efficient removal of microplastics that traditional microplastic filters with larger, micron-scale pores cannot effectively capture.

Adsorption efficiency

Nanomaterial filtration demonstrates significantly higher adsorption efficiency for microplastics compared to conventional microplastic filtration due to its enhanced surface area and reactive sites.

Polymer matrix composites

Polymer matrix composites offer enhanced efficiency in microplastic filtration compared to nanomaterial filtration due to their tailored porosity and mechanical stability, enabling selective capture and durability in water treatment applications.

Selectivity coefficient

Nanomaterial filtration exhibits a higher selectivity coefficient than microplastic filtration, enabling more precise removal of contaminants at the molecular level.

Size exclusion mechanism

Nanomaterial filtration excels over microplastic filtration by using a size exclusion mechanism that targets particles as small as a few nanometers, enabling more effective removal of microscopic contaminants.

Functionalized nanomaterials

Functionalized nanomaterials enhance filtration efficiency by selectively targeting and removing microplastics at the molecular level, outperforming conventional microplastic filtration methods in sensitivity and specificity.

Fouling resistance

Nanomaterial filtration exhibits superior fouling resistance compared to microplastic filtration by effectively preventing pore blockage through enhanced surface chemistry and smaller pore size.

Surface charge interactions

Nanomaterial filtration exhibits superior efficiency over microplastic filtration by leveraging enhanced surface charge interactions that attract and immobilize smaller particles through electrostatic forces.

Water quality indices

Nanomaterial filtration significantly improves water quality indices by more effectively removing microplastics, heavy metals, and organic contaminants compared to conventional microplastic filtration methods.

Regeneration cycles

Nanomaterial filtration systems typically offer significantly higher regeneration cycles than microplastic filtration, enhancing long-term efficiency and cost-effectiveness in pollutant removal.

microplastic filtration vs nanomaterial filtration Infographic

njnir.com

njnir.com