Renewable diesel offers higher energy density and better cold flow properties compared to biodiesel, making it more efficient for engine performance and reducing emissions more effectively. Biodiesel, derived from vegetable oils or animal fats, tends to have higher oxygen content, which can lead to increased nitrogen oxide emissions and potential compatibility issues with existing fuel infrastructure. Both fuels contribute to lower greenhouse gas emissions than traditional petroleum diesel, but renewable diesel's compatibility and stability position it as a superior choice for sustainable transportation.

Table of Comparison

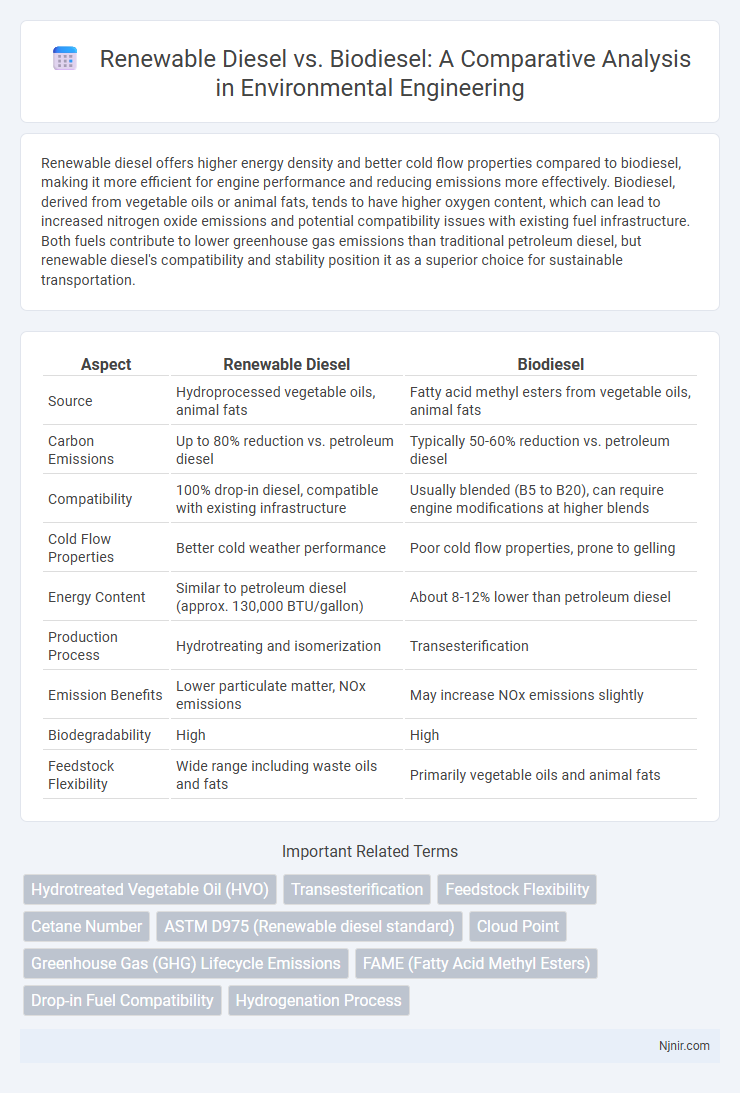

| Aspect | Renewable Diesel | Biodiesel |

|---|---|---|

| Source | Hydroprocessed vegetable oils, animal fats | Fatty acid methyl esters from vegetable oils, animal fats |

| Carbon Emissions | Up to 80% reduction vs. petroleum diesel | Typically 50-60% reduction vs. petroleum diesel |

| Compatibility | 100% drop-in diesel, compatible with existing infrastructure | Usually blended (B5 to B20), can require engine modifications at higher blends |

| Cold Flow Properties | Better cold weather performance | Poor cold flow properties, prone to gelling |

| Energy Content | Similar to petroleum diesel (approx. 130,000 BTU/gallon) | About 8-12% lower than petroleum diesel |

| Production Process | Hydrotreating and isomerization | Transesterification |

| Emission Benefits | Lower particulate matter, NOx emissions | May increase NOx emissions slightly |

| Biodegradability | High | High |

| Feedstock Flexibility | Wide range including waste oils and fats | Primarily vegetable oils and animal fats |

Introduction to Renewable Diesel and Biodiesel

Renewable diesel and biodiesel are both sustainable fuels derived from biomass feedstocks such as vegetable oils, animal fats, and waste oils, but they differ significantly in chemical composition and production processes. Renewable diesel is produced through hydrotreatment, resulting in a hydrocarbon fuel virtually identical to petroleum diesel, offering higher energy density and compatibility with existing diesel engines and infrastructure. Biodiesel is created via transesterification, producing fatty acid methyl esters (FAME) that may require blending with petroleum diesel to meet engine performance and emissions standards.

Production Processes and Feedstocks

Renewable diesel is produced through hydrotreating, where vegetable oils, animal fats, or waste oils undergo hydrogenation to create a high-quality, drop-in fuel compatible with existing diesel engines. Biodiesel is made via transesterification, where oils and fats react with an alcohol, typically methanol, to produce fatty acid methyl esters (FAME) that can blend with petroleum diesel. Renewable diesel feedstocks include soybean oil, used cooking oil, and tallow, while biodiesel commonly uses similar sources but can also incorporate non-food oils like jatropha and algae.

Chemical Composition and Properties

Renewable diesel and biodiesel differ significantly in chemical composition and properties; renewable diesel consists of hydrocarbons chemically similar to petroleum diesel, primarily straight-chain alkanes, whereas biodiesel is composed of fatty acid methyl esters (FAME) derived from vegetable oils or animal fats. Renewable diesel exhibits superior cold flow properties, higher energy content, and greater oxidative stability compared to biodiesel, which tends to have higher viscosity and susceptibility to oxidation due to the presence of ester bonds. These differences impact engine compatibility and emissions, with renewable diesel providing a cleaner burn and better performance in existing diesel engines without modification.

Environmental Impact Assessment

Renewable diesel produces significantly lower greenhouse gas emissions compared to biodiesel, reducing lifecycle carbon output by up to 80% relative to petroleum diesel. Its chemical composition allows it to combust more completely, resulting in lower particulate matter, NOx, and sulfur oxide emissions, which contribute less to air pollution and smog formation. Biodiesel, while biodegradable and renewable, tends to increase nitrogen oxide emissions and may cause higher particulate emissions, posing challenges for strict environmental regulations and air quality standards.

Greenhouse Gas Emissions Comparison

Renewable diesel significantly reduces greenhouse gas emissions by up to 80% compared to conventional diesel, while biodiesel typically offers a 50-70% reduction depending on feedstock and production methods. Renewable diesel's hydroprocessing production process yields a cleaner-burning fuel with lower particulate matter and nitrogen oxide emissions, enhancing overall air quality. Lifecycle analyses show renewable diesel provides greater carbon intensity reductions, making it a more effective option for combating climate change in transportation sectors.

Engine Performance and Compatibility

Renewable diesel offers superior engine performance compared to biodiesel due to its higher cetane number and chemical similarity to petroleum diesel, resulting in smoother combustion and reduced engine deposits. It is fully compatible with existing diesel engines and infrastructure, requiring no modifications, while biodiesel can cause fuel filter clogging and material compatibility issues in some engines. Both fuels reduce greenhouse gas emissions, but renewable diesel's compatibility and performance advantages make it a preferred choice for fleet operators aiming for seamless integration and reliability.

Lifecycle Analysis of Renewable Diesel vs Biodiesel

Lifecycle analysis of renewable diesel reveals lower greenhouse gas emissions compared to biodiesel due to its higher energy density and more efficient combustion processes. Renewable diesel production involves hydrotreating fats, oils, and greases, resulting in a fuel chemically similar to petroleum diesel, which enhances engine compatibility and reduces particulate emissions. Biodiesel, produced through transesterification of vegetable oils or animal fats, tends to have higher lifecycle emissions because of feedstock cultivation, processing energy, and lower fuel efficiency.

Infrastructure and Distribution Challenges

Renewable diesel integrates seamlessly with existing fuel infrastructure and distribution networks due to its chemical similarity to petroleum diesel, enabling use in standard engines without modifications. Biodiesel, composed of fatty acid methyl esters, often requires dedicated handling systems to prevent corrosion and compatibility issues, complicating widespread distribution. These infrastructure differences influence fuel adoption, with renewable diesel benefiting from lower logistical barriers and broader market access.

Regulatory Policies and Incentives

Renewable diesel and biodiesel are subject to distinct regulatory policies and incentives that influence their production and market adoption. The Renewable Fuel Standard (RFS) in the U.S. assigns Renewable Identification Numbers (RINs) that differ by fuel type, with renewable diesel classified as a biomass-based diesel (D4) and biodiesel also eligible for D4 credits but facing stricter feedstock and production criteria. Tax incentives, such as the Biodiesel Mixture Excise Tax Credit, support both fuels, but renewable diesel benefits from more favorable low-carbon fuel standards (LCFS) in states like California due to its superior lifecycle greenhouse gas reduction profiles.

Future Trends and Technological Innovations

Renewable diesel and biodiesel are both advancing through innovations such as hydroprocessing for renewable diesel, which offers higher energy density and better cold flow properties compared to traditional transesterification used in biodiesel production. Future trends indicate a growing industry shift towards renewable diesel due to its compatibility with existing fuel infrastructure and engines, alongside investments in feedstock diversification including algae and waste oils. Enhanced catalytic processes and biotechnological improvements are expected to further reduce production costs and carbon emissions, positioning renewable diesel as a key component in decarbonizing the transportation sector.

Hydrotreated Vegetable Oil (HVO)

Hydrotreated Vegetable Oil (HVO) renewable diesel offers higher energy density, superior cold flow properties, and better engine compatibility compared to traditional biodiesel derived from transesterification processes.

Transesterification

Renewable diesel is produced through hydrogenation and hydrocracking processes, while biodiesel is directly produced via transesterification of vegetable oils or animal fats with methanol or ethanol.

Feedstock Flexibility

Renewable diesel offers greater feedstock flexibility than biodiesel by efficiently processing diverse inputs such as vegetable oils, animal fats, and waste oils into high-quality fuel compatible with existing diesel engines.

Cetane Number

Renewable diesel typically has a higher cetane number ranging from 70 to 90, compared to biodiesel's cetane number of 45 to 65, resulting in improved combustion efficiency and engine performance.

ASTM D975 (Renewable diesel standard)

ASTM D975 specifies quality standards for renewable diesel as a direct petroleum diesel substitute with superior cold flow and stability compared to biodiesel, which follows ASTM D6751.

Cloud Point

Renewable diesel typically has a lower cloud point than biodiesel, making it more suitable for cold weather conditions and improving engine performance by preventing fuel gelling.

Greenhouse Gas (GHG) Lifecycle Emissions

Renewable diesel reduces greenhouse gas lifecycle emissions by up to 80% compared to conventional diesel, while biodiesel typically achieves a 50-60% reduction depending on feedstock and production methods.

FAME (Fatty Acid Methyl Esters)

Renewable diesel is a hydrocarbon fuel chemically similar to petroleum diesel, while biodiesel primarily consists of Fatty Acid Methyl Esters (FAME) derived from transesterified vegetable oils or animal fats.

Drop-in Fuel Compatibility

Renewable diesel offers superior drop-in fuel compatibility compared to biodiesel, enabling seamless use in existing diesel engines and infrastructure without modifications.

Hydrogenation Process

Renewable diesel is produced through a hydrogenation process that removes oxygen from fats and oils, resulting in a high-quality, energy-dense fuel with superior cold flow properties compared to biodiesel, which is typically made through transesterification.

Renewable diesel vs Biodiesel Infographic

njnir.com

njnir.com