Flue gas desulphurization (FGD) effectively removes sulfur dioxide (SO2) emissions from industrial exhaust streams by using chemical absorbents, significantly reducing acid rain and respiratory pollutants. Selective catalytic reduction (SCR) targets nitrogen oxides (NOx) by catalyzing their conversion into nitrogen and water vapor through the injection of ammonia or urea at high temperatures. Integrating FGD and SCR systems enhances overall air pollution control efficiency, addressing multiple harmful emissions for improved environmental compliance.

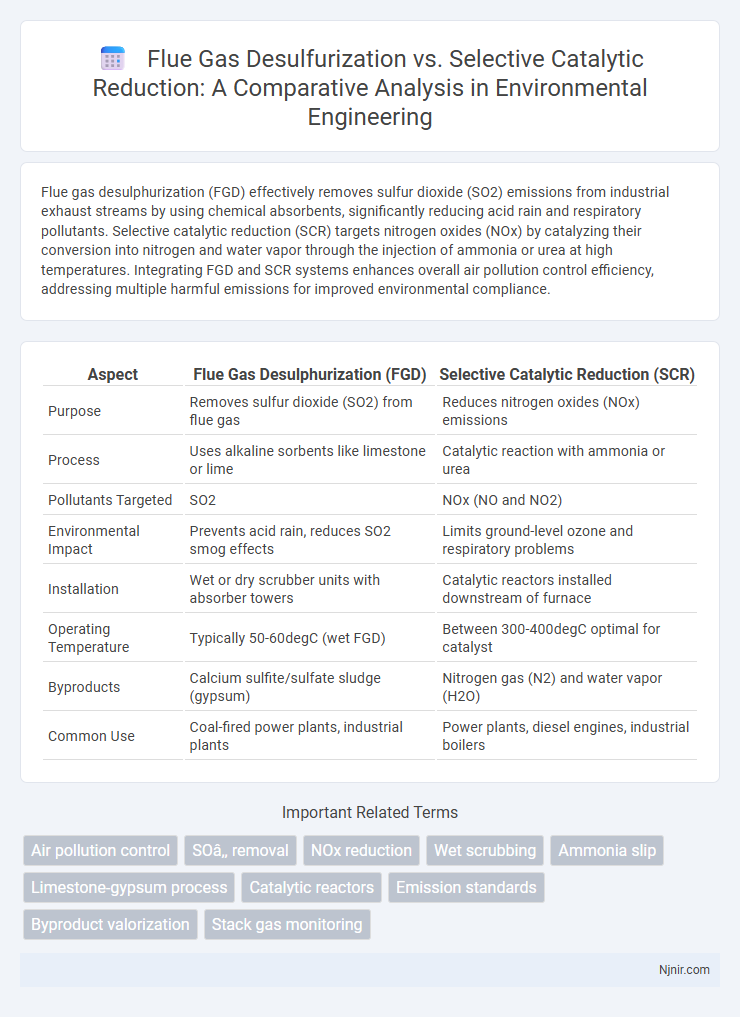

Table of Comparison

| Aspect | Flue Gas Desulphurization (FGD) | Selective Catalytic Reduction (SCR) |

|---|---|---|

| Purpose | Removes sulfur dioxide (SO2) from flue gas | Reduces nitrogen oxides (NOx) emissions |

| Process | Uses alkaline sorbents like limestone or lime | Catalytic reaction with ammonia or urea |

| Pollutants Targeted | SO2 | NOx (NO and NO2) |

| Environmental Impact | Prevents acid rain, reduces SO2 smog effects | Limits ground-level ozone and respiratory problems |

| Installation | Wet or dry scrubber units with absorber towers | Catalytic reactors installed downstream of furnace |

| Operating Temperature | Typically 50-60degC (wet FGD) | Between 300-400degC optimal for catalyst |

| Byproducts | Calcium sulfite/sulfate sludge (gypsum) | Nitrogen gas (N2) and water vapor (H2O) |

| Common Use | Coal-fired power plants, industrial plants | Power plants, diesel engines, industrial boilers |

Introduction to Flue Gas Desulphurization and Selective Catalytic Reduction

Flue Gas Desulphurization (FGD) and Selective Catalytic Reduction (SCR) are key technologies for reducing air pollutants from industrial exhaust gases. FGD primarily targets sulfur dioxide (SO2) emissions through chemical absorption processes, often using limestone or lime. SCR focuses on reducing nitrogen oxides (NOx) by injecting ammonia or urea into the flue gas over a catalyst, converting NOx into nitrogen and water.

Environmental Impact: SO₂ vs NOₓ Emission Control

Flue gas desulfurization (FGD) primarily targets the removal of sulfur dioxide (SO2) from industrial emissions, significantly reducing acid rain and respiratory health issues associated with SO2 exposure. Selective catalytic reduction (SCR) focuses on the reduction of nitrogen oxides (NOx), key contributors to smog formation and ground-level ozone, by converting NOx into harmless nitrogen and water vapor. Both technologies play crucial roles in minimizing air pollution, with FGD addressing SO2 emissions and SCR mitigating NOx emissions, each optimizing environmental impact based on specific pollutant control.

Core Principles of Flue Gas Desulphurization Technology

Flue gas desulphurization (FGD) technology primarily removes sulfur dioxide (SO2) from exhaust gases by using chemical scrubbing processes, most commonly employing limestone or lime slurry to react with SO2 forming calcium sulfite or sulfate. This wet scrubbing method effectively reduces acid rain-causing emissions from coal-fired power plants, ensuring compliance with environmental regulations. Core principles include the absorption of sulfur dioxide in an alkaline medium, efficient mass transfer, and subsequent byproduct handling, distinguishing FGD from selective catalytic reduction (SCR), which targets nitrogen oxides (NOx) removal through catalytic conversion.

Key Mechanisms in Selective Catalytic Reduction Systems

Selective Catalytic Reduction (SCR) systems rely on the injection of a reductant, typically ammonia or urea, into flue gas, which then passes over a catalyst to convert nitrogen oxides (NOx) into nitrogen (N2) and water (H2O). The catalyst in SCR typically consists of materials such as titanium dioxide, vanadium pentoxide, and tungsten trioxide, which facilitate the reduction reaction at temperatures ranging from 250 to 450 degrees Celsius. Unlike Flue Gas Desulfurization (FGD) systems that primarily remove sulfur dioxide (SO2), SCR focuses exclusively on NOx removal through catalytic chemical reduction mechanisms.

Comparative Efficiency in Pollutant Removal

Flue gas desulfurization (FGD) efficiently removes sulfur dioxide (SO2) from industrial emissions, typically achieving removal rates above 90%, whereas selective catalytic reduction (SCR) targets nitrogen oxides (NOx) with reduction efficiencies often exceeding 85%. FGD processes use sorbents like limestone or lime to neutralize SO2, while SCR employs catalysts such as vanadium or zeolites to convert NOx into nitrogen and water. Combined use of FGD and SCR systems maximizes overall pollutant reduction, addressing both acid rain precursors and smog-forming emissions for improved environmental compliance.

Operational Costs and Lifecycle Analysis

Flue gas desulphurization (FGD) systems generally incur higher operational costs due to the extensive use of reagent chemicals like limestone and the management of byproducts such as gypsum, along with significant energy consumption for slurry circulation and fans. Selective catalytic reduction (SCR) units present comparatively lower operational costs, largely driven by ammonia or urea consumption and catalyst replacement schedules, while requiring precise temperature control to maintain efficiency. Lifecycle analysis reveals that while FGD systems have considerable capital and maintenance expenses over a longer operational period, SCR technology often benefits from lower overall lifecycle emissions and cost-effectiveness in NOx reduction, making it favorable in installations prioritizing nitrogen oxide control.

Engineering Challenges and Implementation Considerations

Flue gas desulfurization (FGD) systems face engineering challenges such as managing large volumes of corrosive slurry, ensuring effective reagent consumption, and handling byproduct disposal, which require robust materials and complex waste treatment processes. Selective catalytic reduction (SCR) systems demand precise control of ammonia injection and catalyst temperature to optimize nitrogen oxide (NOx) reduction efficiency while preventing catalyst poisoning and degradation. Implementation considerations for both technologies include integration with existing combustion systems, space constraints, and maintaining operational flexibility to meet stringent environmental regulations.

Regulatory Standards and Compliance Factors

Flue gas desulphurization (FGD) and selective catalytic reduction (SCR) are crucial technologies for meeting stringent regulatory standards on sulfur dioxide (SO2) and nitrogen oxides (NOx) emissions in power plants. FGD systems are designed to comply with Clean Air Act (CAA) Section 112 standards targeting SO2 reduction, typically achieving removal efficiencies above 90%, while SCR units address NOx limits set by National Emission Standards for Hazardous Air Pollutants (NESHAP) and state implementation plans (SIPs). Compliance factors emphasize continuous emissions monitoring systems (CEMS) integration, operational reliability, and adherence to emission limits stipulated by the Environmental Protection Agency (EPA) and international bodies like the European Union Industrial Emissions Directive (IED).

Integration Potential in Existing Industrial Facilities

Flue gas desulphurization (FGD) systems are highly compatible with existing industrial facilities, offering seamless integration due to their modular designs and ability to retrofit onto coal-fired boilers and power plants. Selective catalytic reduction (SCR) technology requires precise placement within flue gas ducts to optimize nitrogen oxide reduction, demanding careful engineering to accommodate catalyst modules without disrupting plant operations. Both technologies can be combined effectively in multi-pollutant control strategies, enhancing compliance with environmental regulations while utilizing existing infrastructure efficiently.

Future Trends in Emission Control Technologies

Flue gas desulphurization (FGD) and selective catalytic reduction (SCR) technologies are evolving with advancements in materials science and automation to enhance efficiency in reducing sulfur dioxide and nitrogen oxides emissions, respectively. Emerging trends include the integration of hybrid systems combining FGD and SCR with carbon capture technologies to meet stringent environmental regulations and improve operational cost-effectiveness. Digital monitoring, AI-driven process optimization, and development of low-pressure drop catalysts are poised to drive the next generation of emission control solutions in power generation and industrial sectors.

Air pollution control

Flue gas desulfurization effectively removes sulfur dioxide from industrial emissions, while selective catalytic reduction targets nitrogen oxides, both crucial for comprehensive air pollution control.

SO₂ removal

Flue gas desulphurization (FGD) effectively removes over 90% of SO2 emissions by using wet or dry scrubbing methods, whereas selective catalytic reduction (SCR) primarily targets NOx reduction and does not significantly reduce SO2 levels.

NOx reduction

Selective catalytic reduction achieves up to 90% NOx reduction by converting nitrogen oxides into nitrogen and water using ammonia, whereas flue gas desulphurization primarily targets SO2 removal with limited NOx reduction efficacy.

Wet scrubbing

Wet scrubbing in flue gas desulfurization efficiently removes sulfur dioxide (SO2) using limestone or lime slurry, contrasting with selective catalytic reduction that targets nitrogen oxides (NOx) through ammonia-based catalysts.

Ammonia slip

Selective catalytic reduction (SCR) systems typically experience ammonia slip ranging from 2 to 10 ppm, whereas flue gas desulphurization (FGD) processes do not produce ammonia slip but primarily focus on removing sulfur dioxide (SO2) from exhaust gases.

Limestone-gypsum process

The Limestone-gypsum Flue Gas Desulfurization (FGD) process efficiently removes SO2 emissions by reacting flue gas with limestone slurry to produce gypsum, whereas Selective Catalytic Reduction (SCR) primarily targets NOx reduction through catalytic reaction with ammonia or urea.

Catalytic reactors

Selective catalytic reduction utilizes catalytic reactors to convert nitrogen oxides into nitrogen and water using ammonia or urea, while flue gas desulphurization primarily employs scrubbers and non-catalytic methods to remove sulfur dioxide from emissions.

Emission standards

Flue gas desulfurization effectively reduces sulfur dioxide emissions to meet stringent environmental regulations, while selective catalytic reduction targets nitrogen oxide emissions to comply with increasingly strict air quality standards.

Byproduct valorization

Flue gas desulphurization generates gypsum as a valuable byproduct used in construction, while selective catalytic reduction primarily produces harmless nitrogen and water without significant byproduct valorization.

Stack gas monitoring

Flue gas desulphurization primarily targets sulfur dioxide removal from stack gases using scrubbers, while selective catalytic reduction focuses on reducing nitrogen oxides through catalytic reaction, both requiring precise stack gas monitoring for emission compliance.

Flue gas desulphurization vs Selective catalytic reduction Infographic

njnir.com

njnir.com