Zero liquid discharge (ZLD) technology eliminates all wastewater by recovering and recycling water, significantly reducing environmental pollution compared to conventional discharge methods that release treated effluents into water bodies. This approach minimizes freshwater consumption and prevents contamination of aquatic ecosystems by capturing contaminants in solid form for safe disposal or reuse. Implementing ZLD systems enhances sustainability and regulatory compliance in industrial wastewater management.

Table of Comparison

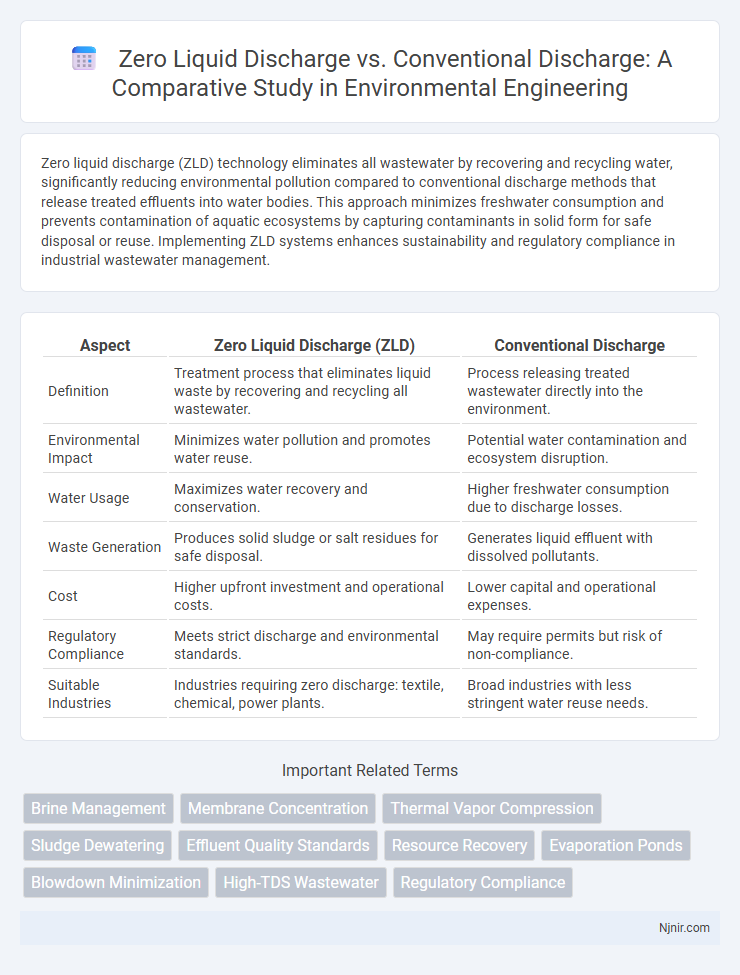

| Aspect | Zero Liquid Discharge (ZLD) | Conventional Discharge |

|---|---|---|

| Definition | Treatment process that eliminates liquid waste by recovering and recycling all wastewater. | Process releasing treated wastewater directly into the environment. |

| Environmental Impact | Minimizes water pollution and promotes water reuse. | Potential water contamination and ecosystem disruption. |

| Water Usage | Maximizes water recovery and conservation. | Higher freshwater consumption due to discharge losses. |

| Waste Generation | Produces solid sludge or salt residues for safe disposal. | Generates liquid effluent with dissolved pollutants. |

| Cost | Higher upfront investment and operational costs. | Lower capital and operational expenses. |

| Regulatory Compliance | Meets strict discharge and environmental standards. | May require permits but risk of non-compliance. |

| Suitable Industries | Industries requiring zero discharge: textile, chemical, power plants. | Broad industries with less stringent water reuse needs. |

Introduction to Zero Liquid Discharge and Conventional Discharge

Zero Liquid Discharge (ZLD) is an advanced wastewater treatment process aimed at eliminating all liquid waste by recovering and recycling water, minimizing environmental impact and complying with stringent discharge regulations. Conventional discharge involves treating wastewater to meet regulatory standards before releasing it into water bodies, often resulting in residual pollutants and lower water recovery rates. ZLD systems integrate technologies such as evaporation, crystallization, and membrane filtration to achieve near-zero effluent, contrasting with conventional methods that rely primarily on biological and chemical treatments.

Fundamental Principles: ZLD vs Conventional Methods

Zero Liquid Discharge (ZLD) fundamentally relies on advanced treatment technologies such as reverse osmosis, evaporators, and crystallizers to recover nearly all water from wastewater, leaving behind solid residues. Conventional discharge methods primarily depend on dilution, biological treatment, and chemical precipitation to reduce pollutant concentration before releasing treated effluent into water bodies. ZLD prioritizes resource recovery and environmental compliance by eliminating liquid waste discharge, whereas conventional methods focus on minimizing environmental impact through pollutant concentration reduction and effluent quality standards.

Regulatory Drivers and Compliance Standards

Zero liquid discharge (ZLD) systems surpass conventional discharge methods by meeting increasingly stringent regulatory drivers aimed at eliminating wastewater discharge and minimizing environmental impact. Regulatory frameworks such as the Clean Water Act in the United States and the European Union's Water Framework Directive enforce strict effluent limits, compelling industries to adopt ZLD technologies to ensure full compliance. Compliance standards demand advanced treatment technologies that recover maximum water and contaminants, reducing pollutants to near-zero discharge levels, whereas conventional discharge typically meets only minimum permissible pollutant thresholds.

Water Recovery and Resource Efficiency

Zero Liquid Discharge (ZLD) systems achieve nearly 100% water recovery by recycling wastewater through advanced treatment technologies like membrane filtration and evaporation, significantly reducing freshwater consumption. In contrast, conventional discharge methods often result in substantial water loss and environmental pollution due to direct effluent release. ZLD enhances resource efficiency by enabling the recovery of valuable salts and minerals from brine, promoting sustainable water management and minimizing ecological impact.

Environmental Impact: Pollution and Ecosystem Protection

Zero liquid discharge (ZLD) systems significantly reduce environmental pollution by eliminating wastewater discharge and enabling complete recovery of water and contaminants, thus protecting aquatic ecosystems from toxic effluents and chemical pollutants typically released in conventional discharge methods. Conventional discharge often leads to contamination of surface and groundwater sources with harmful substances, causing habitat degradation, biodiversity loss, and long-term ecological imbalance. Implementing ZLD technology ensures compliance with stringent environmental regulations and supports sustainable water resource management by minimizing the environmental footprint of industrial processes.

Energy Consumption and Carbon Footprint

Zero liquid discharge (ZLD) systems significantly reduce energy consumption compared to conventional discharge methods by recycling wastewater and minimizing effluent volume, leading to lower steam and power demands during treatment. Conventional discharge often involves large volumes of untreated or partially treated effluent being released, resulting in higher carbon emissions due to energy-intensive processes and pollution control measures. Implementing ZLD can decrease the carbon footprint of industrial water management by reducing greenhouse gas emissions associated with wastewater treatment and effluent disposal.

Operational Costs and Economic Feasibility

Zero Liquid Discharge (ZLD) systems typically incur higher operational costs compared to conventional discharge methods due to advanced treatment technologies like evaporation and crystallization requiring significant energy input. Despite the upfront expenses, ZLD offers long-term economic feasibility by reducing environmental penalties, wastewater disposal fees, and potential regulatory fines. Conventional discharge methods may appear cost-effective initially but often face escalating costs from stringent environmental compliance and potential resource scarcity issues.

Technological Challenges and Innovations

Zero Liquid Discharge (ZLD) systems face significant technological challenges such as high energy consumption, complex brine management, and scaling issues that limit their widespread adoption compared to conventional discharge methods. Innovations in membrane technologies, advanced crystallizers, and integration of renewable energy sources are enhancing the efficiency and cost-effectiveness of ZLD processes. These advancements contribute to improved water recovery rates and reduced environmental impact, positioning ZLD as a sustainable alternative to traditional liquid discharge systems.

Integration with Sustainable Industry Practices

Zero liquid discharge (ZLD) systems eliminate wastewater discharge by recycling and recovering all water, aligning with sustainable industry practices focused on reducing environmental impact. Conventional discharge methods release treated effluents into water bodies, posing risks of pollution and resource depletion, which contradicts circular economy principles. Integrating ZLD enhances water reuse efficiency, supports regulatory compliance, and promotes responsible resource management essential to sustainable industrial operations.

Future Outlook for Wastewater Management

Zero liquid discharge (ZLD) systems represent the future of sustainable wastewater management by almost entirely eliminating liquid waste, thereby preventing environmental contamination and promoting water reuse. Conventional discharge methods, which release treated effluents into water bodies, face increasing regulatory constraints and rising concerns over water scarcity and pollution. Advancements in membrane technologies, evaporation, and crystallization processes position ZLD as a critical solution to meet stringent discharge regulations and support circular water economies.

Brine Management

Zero Liquid Discharge (ZLD) systems achieve complete brine management by eliminating liquid waste through advanced evaporation and crystallization processes, contrasting with conventional discharge methods that release concentrated brine into the environment, posing greater ecological risks.

Membrane Concentration

Membrane concentration in zero liquid discharge systems significantly reduces wastewater volume by recovering valuable solutes, unlike conventional discharge methods that release untreated effluents.

Thermal Vapor Compression

Thermal Vapor Compression in zero liquid discharge systems enhances water recovery and minimizes brine disposal compared to conventional discharge methods by recycling vapor to boost evaporation efficiency.

Sludge Dewatering

Zero liquid discharge systems enhance sludge dewatering efficiency by minimizing water content and reducing sludge volume compared to conventional discharge methods.

Effluent Quality Standards

Zero liquid discharge systems consistently achieve effluent quality standards far superior to conventional discharge methods by eliminating liquid waste and minimizing pollutant release.

Resource Recovery

Zero liquid discharge systems maximize resource recovery by recycling and reusing all wastewater constituents, unlike conventional discharge methods that often waste valuable water and minerals.

Evaporation Ponds

Zero liquid discharge systems eliminate waste by fully recycling water and producing no liquid effluent, whereas conventional discharge relies on evaporation ponds that can cause environmental contamination through seepage and air emissions.

Blowdown Minimization

Zero liquid discharge systems minimize blowdown by recycling and reusing wastewater, significantly reducing environmental impact compared to conventional discharge methods.

High-TDS Wastewater

Zero liquid discharge (ZLD) systems achieve near-complete recovery of water and minerals from high-TDS wastewater, eliminating liquid waste and reducing environmental impact compared to conventional discharge methods that release concentrated brine into water bodies.

Regulatory Compliance

Zero liquid discharge systems ensure strict regulatory compliance by eliminating wastewater discharge and minimizing environmental pollution compared to conventional discharge methods that often lead to regulatory challenges and fines.

zero liquid discharge vs conventional discharge Infographic

njnir.com

njnir.com